Senieer at CPHI Shanghai 2025

Senieer is participating the CPHI Shanghai 2025 exhibition which started from June 24, 2025, and ended at June 26, 2025. In the exhibition, Senieer will showcase its latest pharmaceutical equipment, production line, and communicates with peers and customers from all over the world. From solid dosage form, powder line, packaging line, semi solid, bottle/liquid filling line, to water treatment and cleanroom system, Senieer offers GMP turnkey project for clients. Customization service is available. Senieer will design and manufacture as per URS and fully complies with related international standards such as CMP. Strict quality control system ensures excellent product performance.

- June 23, 2025

4 Details You Must Know About Pin Mill

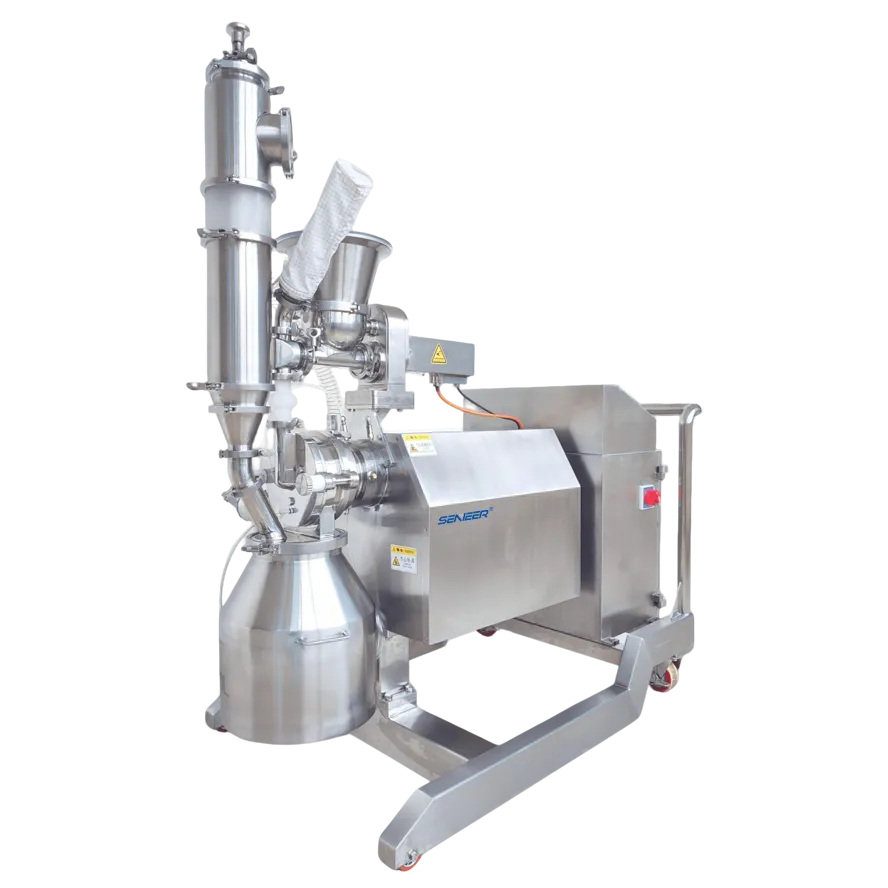

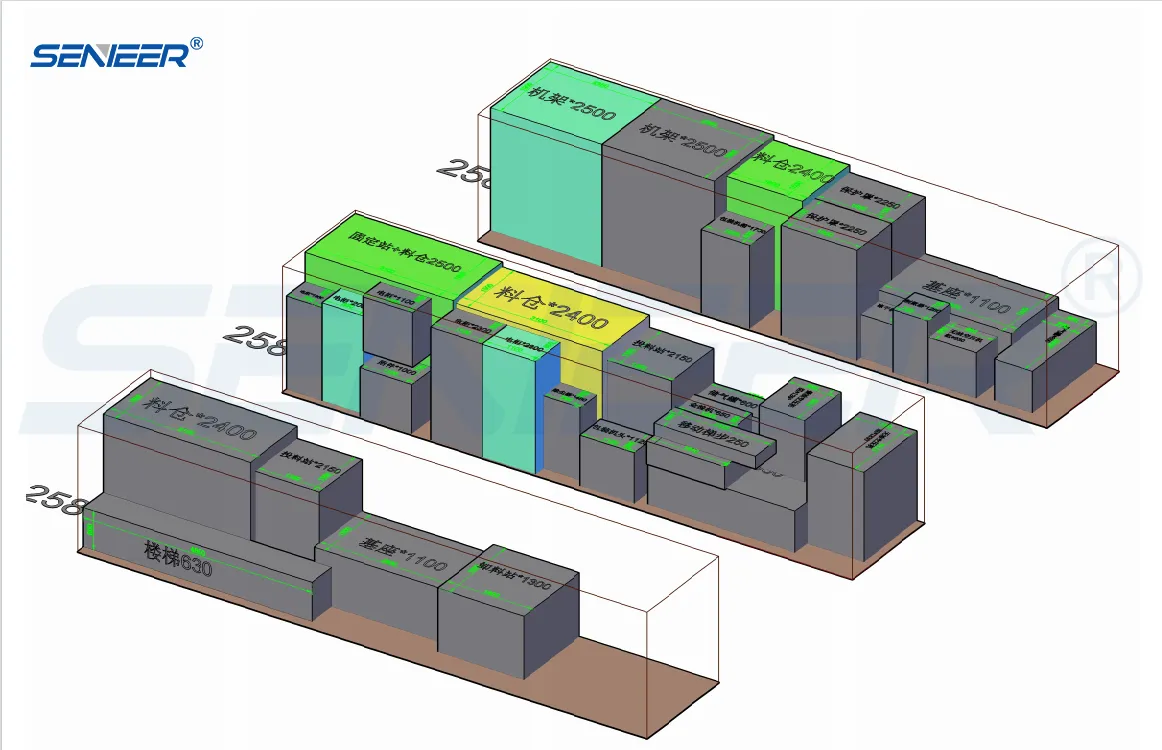

Senieer’s pin mill is a high-speed impact precision grinding mill, which can process various types of materials. The minimum particle size of processed materials can reach 5μm (largely influenced by material characteristics).

Case Study: Customized Coffee Processing Equipment Solutions Help Malaysian Coffee Brands Achieve Dual Upgrades in Quality and Efficiency

Roll compactor(or roller compactor) is a professional machine used mainly for the dry granulation of various substances such as those heat or moisture sensitive materials.

Tablet compression machine is mainly used to transfer powdered materials into tablets by compression. These compressed tablets usually have a uniform size and shape. It is also called tablet press machine, tablet making machine, etc.

Powder Packaging Machine

Powder packaging machine is a professional equipment used to fill and seal various bags such as sachet, pouch, stick and strip. For convenient use, except for filling powders, it can also be applied to fill other materials like granules or tablets or bulks.

Top 3 Capsule Filling Machine Manufacturers And Suppliers In Arabia

This article will introduce to you the top 3 capsule filling machine manufacturers and suppliers in the Arabian peninsula. Each has its exclusive technology and advantages.

What Is Pouch Packing Machine?

Pouch packing machine is an automatic packaging machine used specifically for filling various products such as food, medicine and agricultural products into pouches and sealing them.

Powder Packaging Machine

Powder packaging machine is a professional equipment used to fill and seal various bags such as sachet, pouch, stick and strip. For convenient use, except for filling powders, it can also be applied to fill other materials like granules or tablets or bulks.

What Is Pouch Packing Machine?

Pouch packing machine is an automatic packaging machine used specifically for filling various products such as food, medicine and agricultural products into pouches and sealing them.

Top Spray Fluid Bed Granulator is an efficient equipment dedicated to powder granulation and drying. It is widely used in the pharmaceutical, food and fine chemical industries.

The multifunctional fluidized bed processor, also known as a fluidized bed coating machine, is a device that processes granules using a bottom spray technique.

The pharmacy fluid bed processor integrates drying, granulation, coating, and mixing functions into a single machine.

The FBG 200 Fluid Bed Granulator is a common piece of pharmacy equipment, which can realize integrated operations of mixing, granulating, and drying in one process.

The coating effect of top spray in the fluid bed is relatively poor.

The high-speed mixer granulator, also known as the high-efficiency wet granulation machine, is a high-efficiency wet mixing and granulation device that accomplishes the mixing, humidification, and granulation processes in a single operation.

Hammer mill machine is a kind of high- efficiency crusher, Different crushing methods can be selected according to the different physical properties of materials, and the raw materials of different sizes can be crushed into uniform particles.

Dry granulation and wet granulation are two core granulation processes in pharmaceutical production, with the key difference lying in the use of wetting agents/adhesives, as well as the resulting variations in process routes, applicable materials, and product characteristics.

The SPM series pin mill is an industrial ultrafine grinding device that reduces materials to micron-scale through impact, grinding, and shearing actions between a high-speed rotating pin rotor and stator.

The SD Series Drum is an exquisite stainless steel storage container for processed products in the pharmaceutical, food, and chemical sectors.

Senieer’s pin mill is a high-speed impact precision grinding mill, which can process various types of materials. The minimum particle size of processed materials can reach 5μm (largely influenced by material characteristics).

A jet mill is a type of equipment used for ultra - fine grinding of powders that utilizes high - speed airflow as a carrier.

The industrial rapid mixer granulator, also known as the high shear mixer granulator or wet granulator, is a common granulation machine widely used in the fields of pharmaceuticals, nutrition, and veterinary medicine.

The Blister Packaging Machine is used for packaging capsules, tablets, fudge, and other materials in pharmaceutical processes.

Post bin blender, also named single column bin blender,is a high-efficiency mixing equipment widely used in pharmaceutical, food, chemical, and other industries.

Hammer mill machine is a kind of high- efficiency crusher, Different crushing methods can be selected according to the different physical properties of materials, and the raw materials of different sizes can be crushed into uniform particles.

LVM vacuum conveyor with cone mill is a kind of process equipment and used to transfer the materials and complete the mill operation by conical mill.

The Blister Packaging Machine is used for packaging capsules, tablets, fudge, and other materials in pharmaceutical processes.

The STC series tablet coating machine, also known as a film coating machine, is primarily used in the fields of pharmaceuticals, food, and biological products.

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line