Current Product: Mixing Tank

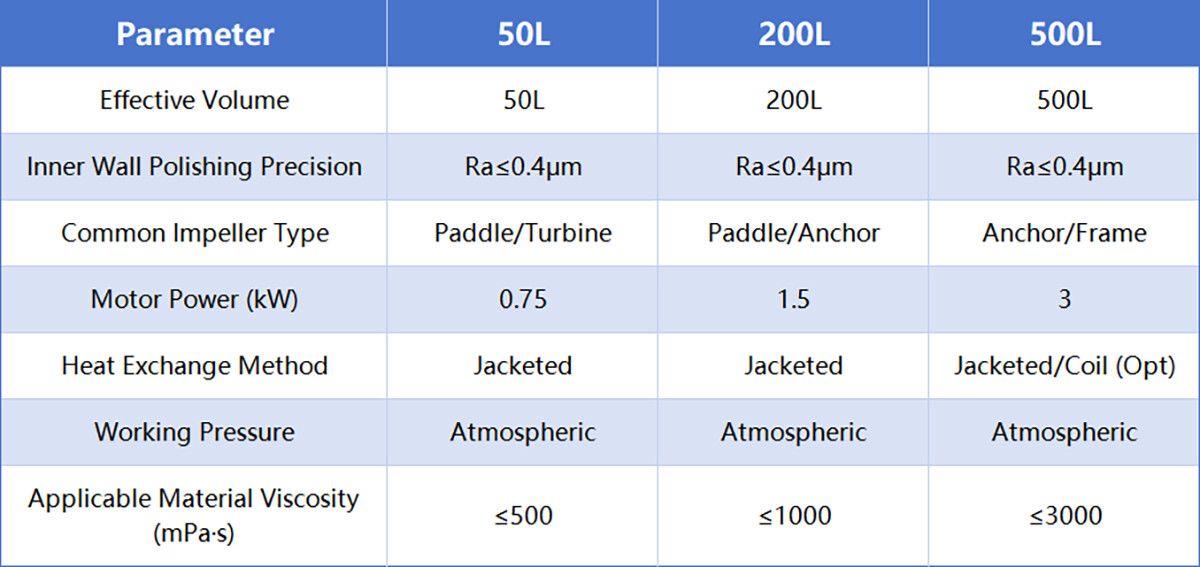

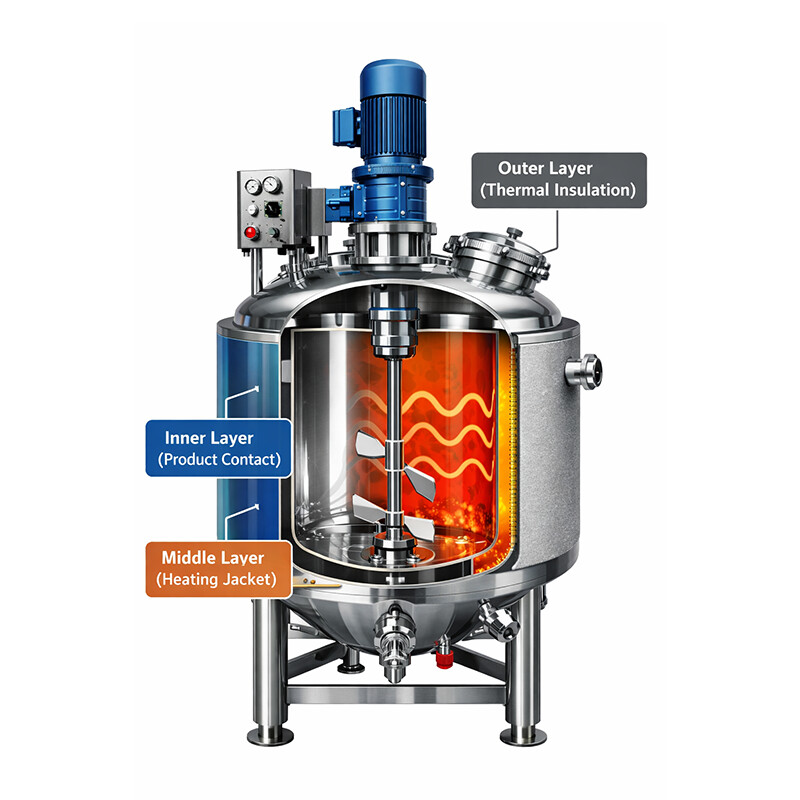

Mixing tank, as a frequently used industrial piece of equipment, is made of 316L stainless steel, which ensures excellent corrosion resistance and durability. The uniform mixing function is achieved through a well-designed agitator system, enabling efficient blending of various materials. Moreover, the heating and cooling feature allows for precise temperature regulation during the mixing process, meeting different production requirements.

Senieer provides economically feasible solutions and is committed to solving your mixing problems.