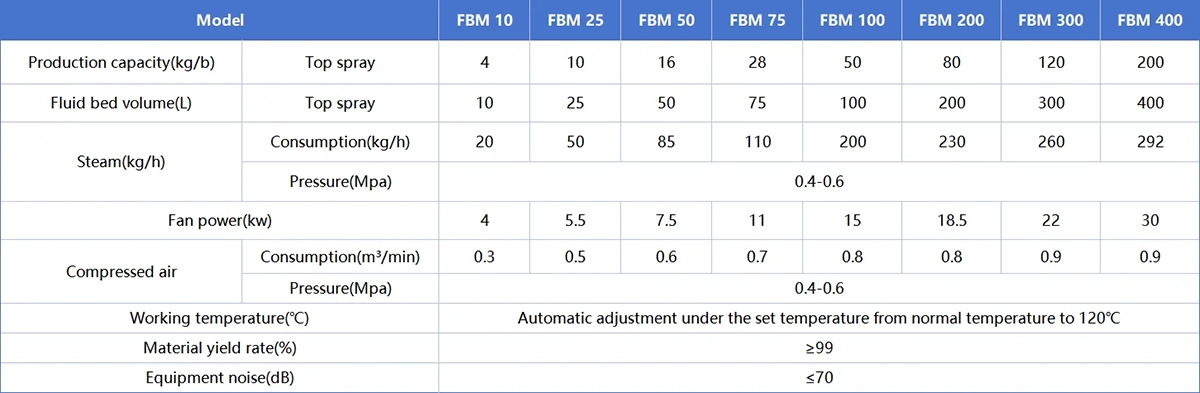

Current Product: Top Spray Fluid Bed Granulator

This series of top-jet fluidized bed granulation dryers is a standardized product specially developed for the granulation and drying process of solid preparations. It has a mature structure and stable operation, and is suitable for laboratory, pilot scale and industrial production.The equipment integrates granulation and drying, and adopts the classic top spray granulation process. It can complete the granulation and moisture removal of materials in the same closed system, effectively reducing intermediate transfer, reducing pollution risks, and improving production efficiency.