What Is Fluid Bed Dryer?

Fluid bed dryer is a drying equipment which is widely used in the pharmaceutical, food, chemical and many other industries, for effectively and uniformly drying materials of particles or powders. The core principle is the fluidization technology which makes the solid particles suspend and quickly dehydrate in the hot air flow to achieve fast drying.

Key Factors Need to Be Considered by Both Suppliers and Clients

When choosing fluid bed dryer, there are many factors need to be taken into consideration. But the most important points is following: first, clients need to tell the capacity which they want to achieve in the operation of fluid bed dryer or other machines. After making sure the capacity, the manufacturers also need to learn about more detailed information like voltage of local place, requirements of clients, technical parameters, etc, and then begin the manufacturing of specific equipment. It is noted that all details need to be considered completely and each part should reach a consensus in every details to avoid some unnecessary disputes in the future.

Configuration Of Fluid Bed Dryer

Air Supply System

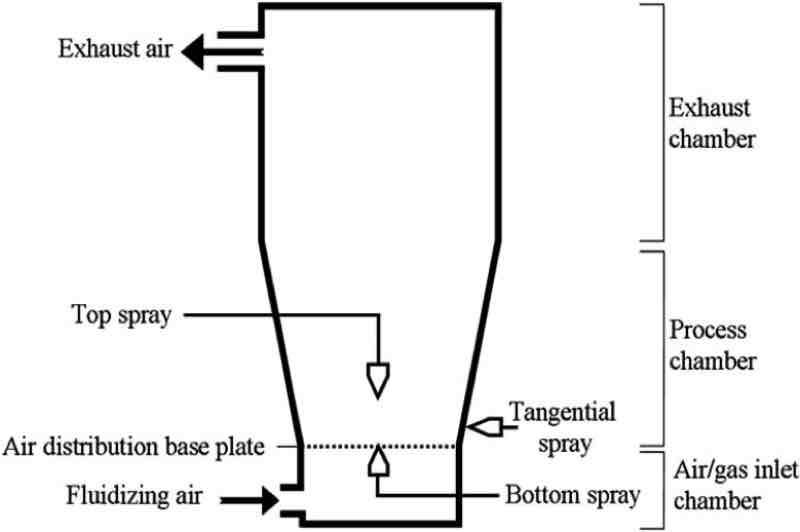

The core function of air supply system is offering uniform and stable air flow to achieve the fluidized state of solid particles so as to enhance the heat and mass transfer efficiency. Its key parts include: air inlet duct, rectifying tube, air chamber, and air distributor plate.

- Air inlet duct: the duct used for introducing air flow into system or equipment.

- Rectifying tube: setting rectifying tube in the vertical air inlet tube to reduce the skewed speed of air flow to achieve the uniform distribution of air flow.

- Air chamber and air distributor plate: air flow enter into the air chamber through the diffusion tube, then enter into the fluid bed through air distributor plate. The air distributor plate plays the function of supporting solid particles and uniformly distribute air flow.

Heating Devices

There are mainly two heating ways: electric heating and steam heating. Each heating way has its unique advantages and disadvantages.

- Electric heating: it is applicable to the situations where needs to control the temperature precisely. By electric heating units, convert electric energy into thermal energy, heating air flow. Its advantages are fast heating speed and high precise temperature control. It is suitable for small fluid bed dryer or processes which has a high requirement for temperature control.

- Steam heating: utilize the latent heat of steam to heat air flow or other media. Steam transfer heat to the air flow by a heat exchanger, making the air reach the needed temperature. It features high thermal efficiency and good thermal stability, is suitable for large scale industrial production, especially the pharmaceutical and chemical industries.

It is noted that in the electric heating, it usually doesn’t need cold or hot air damper, but needs anemometer. Whereas in the steam heating, it is usually equipped with cold and hot air damper.

Dehumidification Method

The dehumidification methods of fluid bed dryer usually have two kinds: cooling coil dehumidification and rotary wheel dehumidification.

- Cooling coil dehumidification: make use ofa surface cooler to reduce the air temperature, causing the water vapor in the air to condense, thus achieving the purpose of dehumidification. This method is suitable for situations where has high requirements for the air humidity, which can effectively control the relative humidity of air. The temperature of inlet water is 5~7℃, that of outlet water is about 12~15℃.

- Rotary wheel dehumidification: adsorb the moisture in the air through the rotary adsorbent, and then heat and dehydrate it in the regeneration zone to achieve continuous dehumidification.The advantages of this dehumidification method is its excellent dehumidification effect, suitable for high humidity environments, has a wide applications especially in the drying process of pharmaceutical industry.

after cooling coil dehumidification, the water content per cubic meter can be reduced to below 10g. compared to the cooling coil dehunidification method, the rotary wheel dehunidification has a better effect in dehumidification. It can reduce the water content per cubic to below 3g,

Other Parts Of Fluid Bed Dryer

Secondary dust removal(optional): if there is no central dust removal, it can be equipped with secondary dust removal device, such as cyclone separator or baghouse dust collector, to have a further treatment of waste gas discharged from fluid bed dryer, removing the dust particles in it reducing its impact on the environment.

Automatic washing machine: Senieer offers automatic washing machine which can be shared between fluid bed dryer and rapid mixer granulator(high shear mixer), achieving WIP.

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line