Home » Tablet Compression Machine

Tablet Compression Machine

Tablet Compression Machine

Tablet compression machine is mainly used to transfer powdered materials into tablets by compression. These compressed tablets usually have a uniform size and shape. It is also called tablet press machine, tablet making machine, etc. The most common industries this machine are used including pharmaceutical, nutraceutical and chemical. From single punch to rotary tablet press, the types of tablet compression machine are diverse and each is designed for specific conditions.

Features of Tablet Compression Machine

- From lab to large scale of production, meeting multiple needs.

- From tens of thousands to hundreds of thousands.

- Automatic operation make powder filling and tablet compression easy.

- Recycling device reduces the materials waste.

- Can freely control the weight, hardness and size of tablets.

Chapter 1:what isTablet Compression Machine Used For?

Tablet compression machine can achieve multiple functions such as uniform tablet size, density, weight, and production efficiency. According to authoritative report, the tablet press and package market is rapidly increasing and the market size reaches billions of US dollars.

The driven factors include increasingly ageing population and the importance attached into health by people.

The tablet compression machine is mainly used in the pharmaceutical, nutraceutical, chemical and cosmetic industries. In a complete tablet production line, it is usually used in conjunction with bin blender, blister packing machine, cartoning machine, etc.

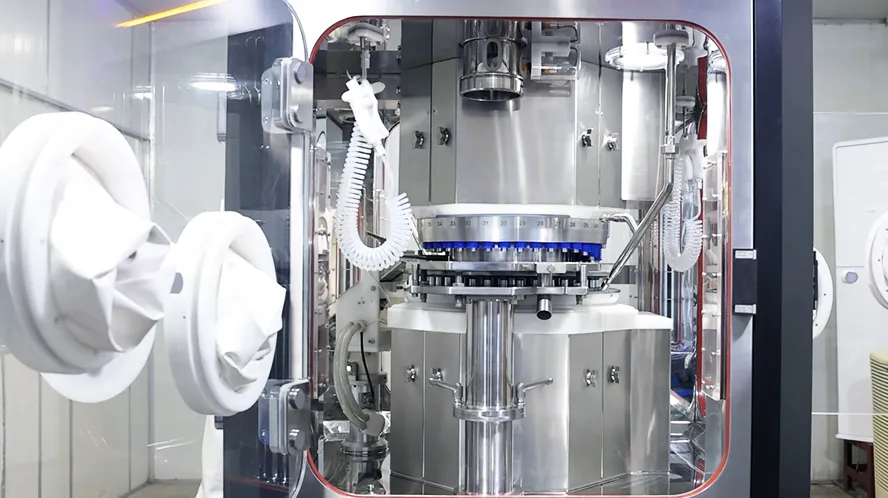

Chapter 2: Working principle of Tablet Compression Machine

The working process of tablet compression machine is briefly divided into the following steps: powder filling, tablet press, tablet discharge.

There are upper punch, lower punch and middle. The lower punch locates under the middle die. It moves upwards into the middle die hole. Then materials like powder or granules are filled into the middle hole by feeder. After filling, the upper punch moves downwards into the middle die hole. After compression between two punches, the tablets are formed. The compressed tablets are then pushed out by lower punch and go into the material bin.

Chapter 3:Structure And components of Tablet Compression Machine

Although tablet compression machine has many different types, there are some basic components and parts which can help you understand the structure and working process of tablet compression machine.

Hopper

It is a bin for storing materials like powders or granules. Filling material are fed into the die before compression.

Feed Cup

It is used to transfer materials from hopper into the die cavity. This device can ensure materials are filled into the die cavity evenly, and it can also control the filling speed and volume, which is important to produce tablets with uniform shape, weight and quality.

Die

It is the mold in which the tablets are pressed , its shape usually is round. This part is key during the formation of tablets as it determines the shape, size and thickness of tablets.

Punch

The function of punches is to compress powders or granules into tablets with specific shape or size. It is divided into upper and lower punch, and they exert force on the materials together. The shape and size of punches determine that of tablets. So, the punches can be designed as round, oval and other specific shapes to meet different needs.

Pressing Wheels

It is responsible for driving die and punch to rotate to achieve the continuous tablet compression. It is divided into upper pressing wheel and lower pressing wheel.

Ejection Cam

The function of ejection cam is to eject compressed tablets out of die cavity. During the rotation of turret, the ejection cams push lower punches upwards to eject tablets out of die cavity in the correct time point.

Chapter 4:How To Maintain a Tablet Compression Machine?

To ensure the normal and excellent operation of machine, necessary and regular maintenance is needed. The maintenance includes the following aspects:

Inspection

In order to ensure the long operation of machine, the regular inspection is the most important. By often monitoring and inspection, the signs of breakdown, wear, loose or damage can be known early and repair them to avoid further damage.

Cleaning

Regular cleaning is important, which can reduce dust accumulation, prevent cross-contamination, extend the service life, enhance production efficiency, and guarantee the product quality. The cleaning include internal and external. The optional cleaning way have WIP(wash in place) and CIP(clean in place).

Lubricating

Lubrication is necessary in the ordinary maintenance of machine. It is unavoidable that some accessories and machine parts rust as the time goes by. Add lubricating oil regularly on these parts can effectively avoid the conditions of those phenomenon.