Current Product: Homogeneous Machine

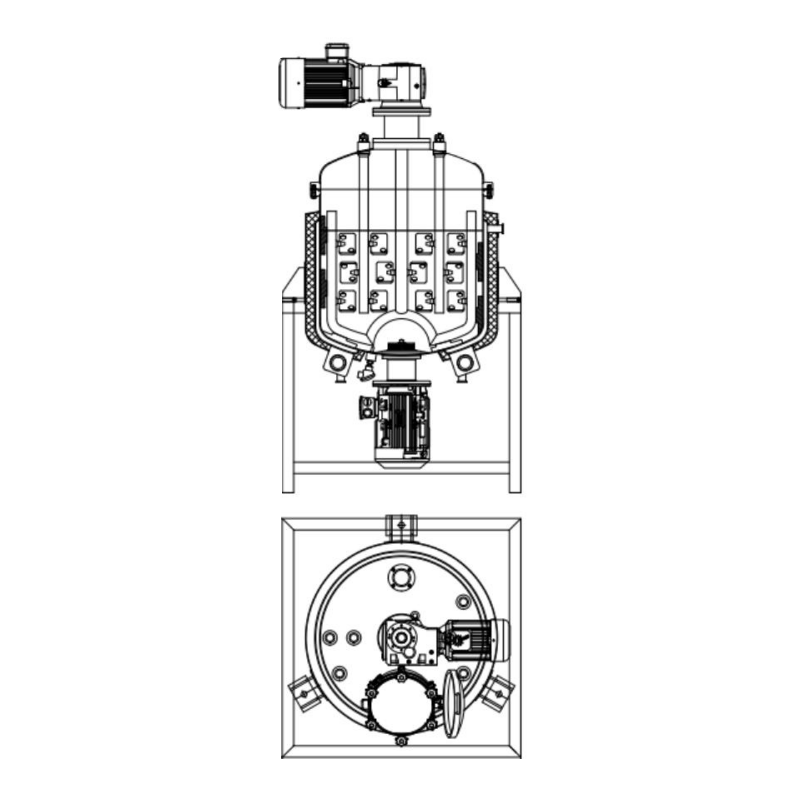

Homogeneous machine is widely used in various industries such as food, pharmaceuticals, cosmetics, and chemicals. In the food industry, for instance, it can be used to improve the texture and stability of products like milk, yogurt, and ice cream by breaking down fat globules and ensuring a consistent distribution. In the pharmaceutical field, homogeneous machines help in creating uniform drug formulations, enhancing the bioavailability and efficacy of medications. For cosmetics, they can achieve a fine and even dispersion of ingredients, resulting in better-quality products with improved sensory properties. In the chemical industry, these machines are essential for producing homogeneous mixtures of different substances, facilitating various chemical reactions and processes.

Are you confused about the model selection? Talk to Our Mixing System Engineer