Current Product: Industrial Mixing Tank

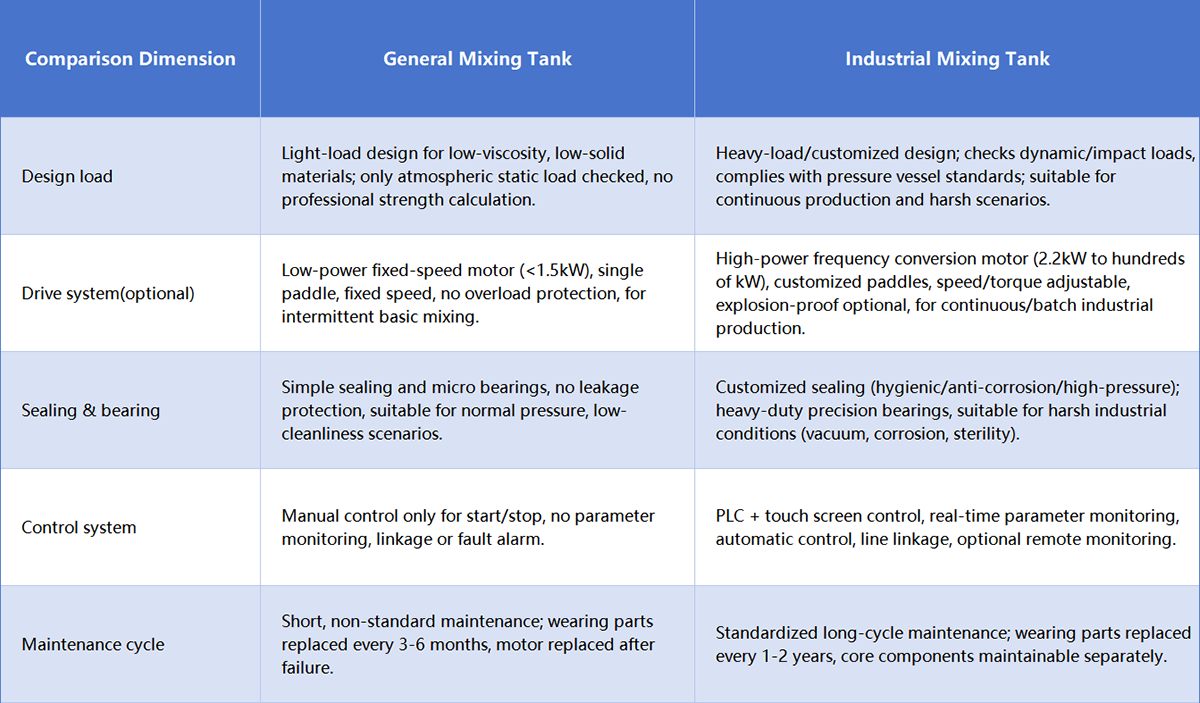

Industrial Mixing Tank offers a variety of material options, yet the mainstream materials are primarily stainless steel 304/316L. This is because it has a longer service life, moderate strength, and a wider range of applicable materials compared to other materials. If you have strict standards for long-term heavy-duty continuous operation, then Industrial Mixing Tank is your best choice.

Are you confused about the model selection? Talk to Our Mixing System Engineer