Video

Senieer® technical team memebers improve complete project services (also called one-stop solution services) from consulting to design and is committed to providing customers with unmanned factory construction.

Senieer Automated Granulation Line

The Senieer Granulation Line offers a complete granulation process designed for various industries, including pharmaceuticals, food, and chemicals. The system integrates multiple stages of granulation, including mixing, granulating, drying, and sieving, to provide a fully automated, streamlined process. With improved project services(also called one stop solution), Senieer can custom design and manufacture products as per your requirements to improve the production process of your granulation line.

- June 19, 2024

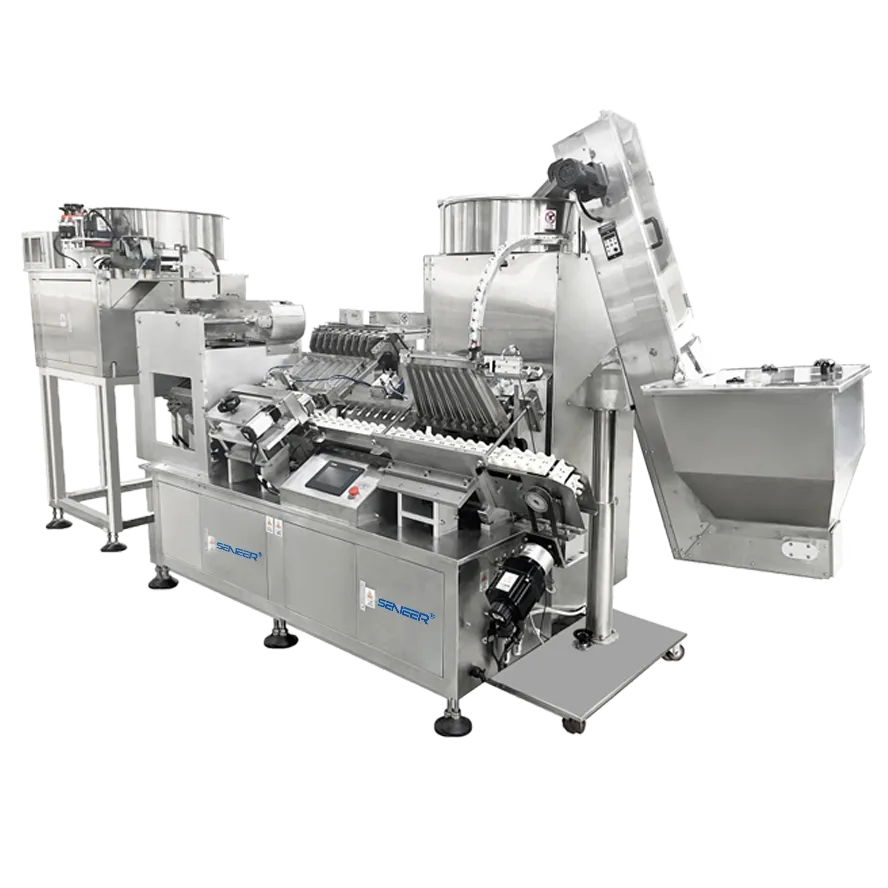

Senieer Integrated Packing Line

Senieer offers a set of smart and automated packing line, including counting, blister packing, sealing, folding and cartonning machines. Each part is integrated together to form a efficient packing line. The counting machine counts, the blister packing machine forms blister packs, the sealing machine seals them, the folding machine converts flat material into cartons, and the cartoning machine opens and seals cartons for distribution.

- June 19, 2024

Senieer Powder Line

Senieer has a complete set of powder production line which is widely used in the pharmaceutical, food and chemical industries. It contains Dust-free feeding machine, conveying machine, reactor, metal detector, and sealing machine. Senieer powder line is designed to focus on energy conservation and high efficiency, with low operating costs. The entire production line adopts sealed transportation to reduce dust leakage and protect the environment.

- June 19, 2024

Choose Your Interested Production Line

All Videos

Senieer products cover the whole pharmaceutical production line including solid dosage line, packing line, powder line, liquid filling line, etc. It provides equipment including rapid mixer granulator, fluid bed system(dryer/granulator/processor), dry & wet cone mill, ibc bin, lifters, vacuum conveying, bin blenders, tablet press machine, tablet coating machine, capsule filling machine, etc.

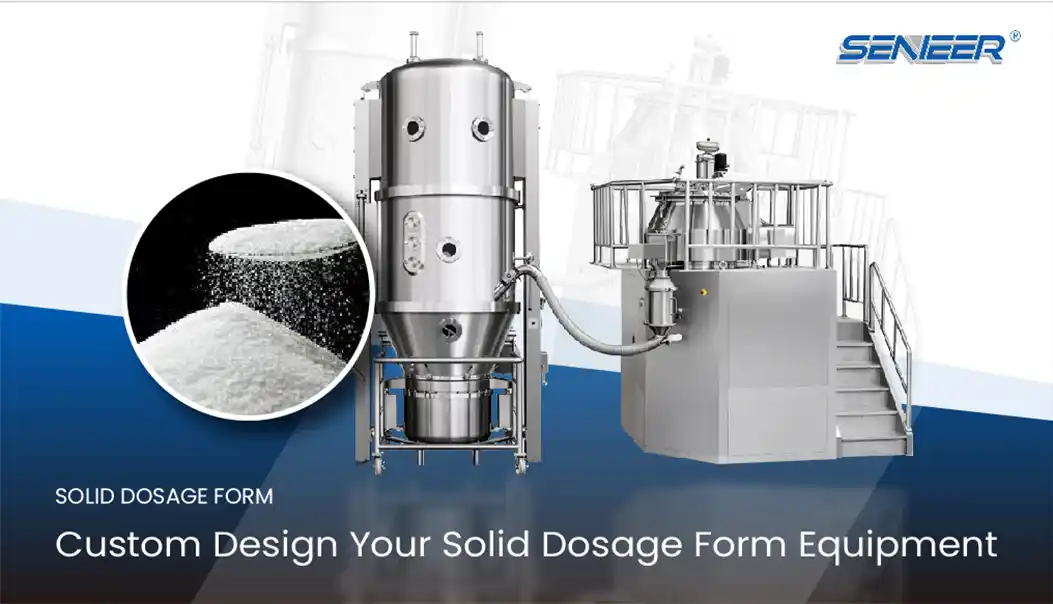

Solid Dosage Form

Senieer provides comprehensive solid dosage production equipment, covering the entire production process from raw material handling to the final packaging. Main equipment includes hammer mill, bin blender, rapid mixer granulator, fluid bed system, tablet press and coating machines, capsule filling machine, etc. Granulation line combines both granulation and drying processes to ensure continuous and stable production, it can highly increase the yield of finished

products. Senieer solid dosage production line integrates a set of key processes, ensuring high efficient, stable and international standards-compliant production.

Packing Line

Senieer packing line covers the entire process from primary packaging to secondary packaging and can meet the packing needs of different products. Main functions include automated cartoning, sealing, labeling and palletizing. Senieer packing line adopts advanced automation technology, significantly enhancing the production efficiency and reducing labor cost.

Powder Line

Senieer powder line is an automated, efficient and environmental-friendly one-stop solution, covering the whole production process from raw material handling to the final packaging. It is widely used in the pharmaceutical, food and chemical industries. It features low energy consumption and low cost, high accurate measurement, environmental-friendly design and automated control(PLC control system), etc.

Semi-Solid

Senieer also offers semi-solid one-stop solution for clients. Semi solid dosages usually include ointments, creams, gels, pastes, etc., and are mainly used for topical administration. Its production process varies according to the differences of dosage forms and use. Main equipment includes vacuum emulsifying mixer, tube filling machine, etc.

Cleanroom

Senieer offers one-stop solutions for clean room, aims to solve and satisfy strict requirements for production environment in pharmaceutical, food, chemical and cosmetics industries. Senieer clean room system includes clean room panel, clean room window, clean room door, etc. These equipment and accessories are dedicatedly designed to ensure the airtightness and efficient operation of the clean room.

Cleanroom

Water Treatment

Water plays an important role in the industrial production and it usually has strict hygienic standards. Senieer water treatment system is mainly used in producing purified water and water for injection, and it meets strict standards for pharmaceutical industry. After pre-treatment, reverse osmosis and post-treatment(such as ion exchange, EDI, etc.), purified water will be transferred into various points.

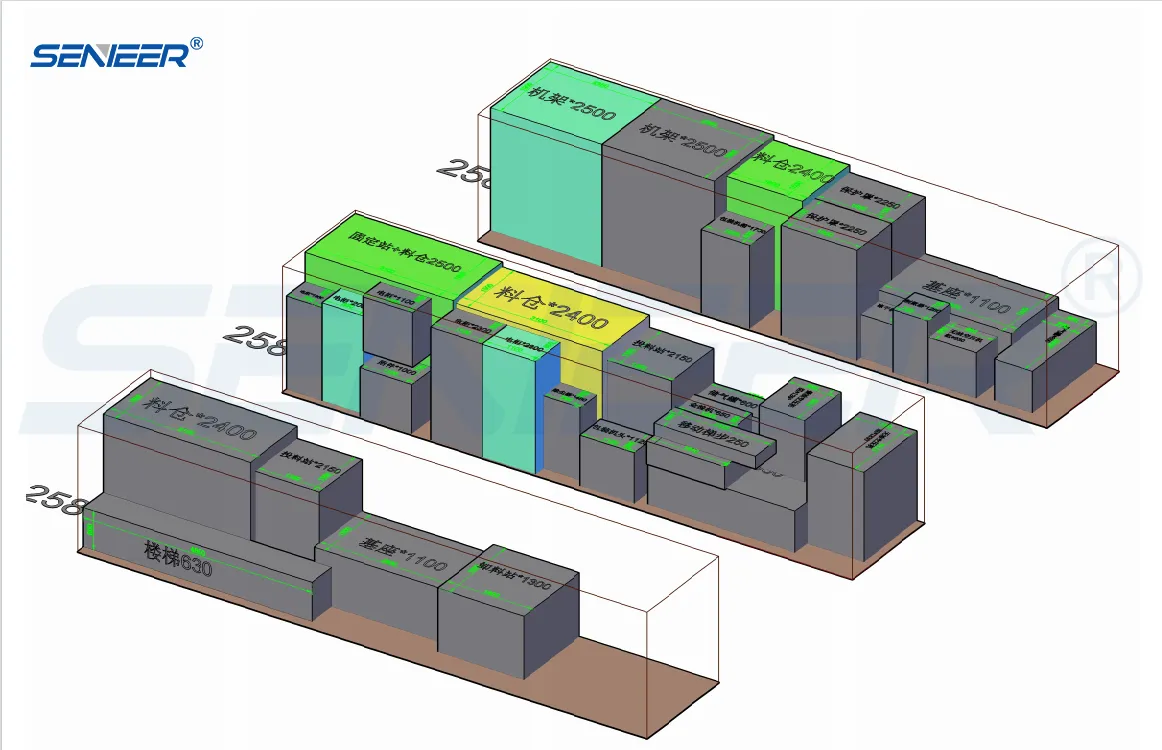

Turnkey Project

Senieer offers one-stop turnkey projects for clients. From projects consultancy & design, equipment manufacture & customization, to installation & commissioning, training & technical support, Senieer provides clients with full-process services. Custom design as per client’s processes and layout requirements and all equipment complies with international standards such as ISO 9001 and CE, etc.

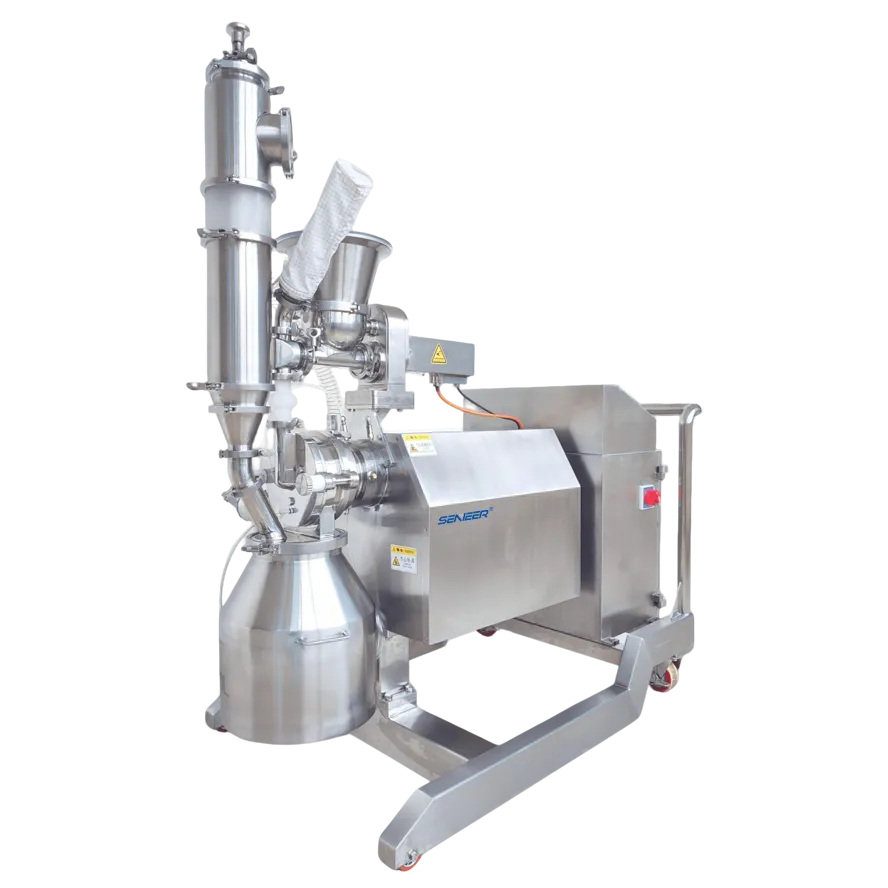

The SPM series pin mill is an industrial ultrafine grinding device that reduces materials to micron-scale through impact, grinding, and shearing actions between a high-speed rotating pin rotor and stator.

The SD Series Drum is an exquisite stainless steel storage container for processed products in the pharmaceutical, food, and chemical sectors.

Senieer’s pin mill is a high-speed impact precision grinding mill, which can process various types of materials. The minimum particle size of processed materials can reach 5μm (largely influenced by material characteristics).

A jet mill is a type of equipment used for ultra - fine grinding of powders that utilizes high - speed airflow as a carrier.

The industrial rapid mixer granulator, also known as the high shear mixer granulator or wet granulator, is a common granulation machine widely used in the fields of pharmaceuticals, nutrition, and veterinary medicine.

The Blister Packaging Machine is used for packaging capsules, tablets, fudge, and other materials in pharmaceutical processes.

Post bin blender, also named single column bin blender,is a high-efficiency mixing equipment widely used in pharmaceutical, food, chemical, and other industries.

Hammer mill machine is a kind of high- efficiency crusher, Different crushing methods can be selected according to the different physical properties of materials, and the raw materials of different sizes can be crushed into uniform particles.

LVM vacuum conveyor with cone mill is a kind of process equipment and used to transfer the materials and complete the mill operation by conical mill.

The Blister Packaging Machine is used for packaging capsules, tablets, fudge, and other materials in pharmaceutical processes.

The STC series tablet coating machine, also known as a film coating machine, is primarily used in the fields of pharmaceuticals, food, and biological products.

The pharmaceutical hammer mill, also referred to as a pharmaceutical pulverizer, is constructed entirely from 316L stainless steel.

The pharmaceutical fluid bed dryer is a drying equipment used for high - rate moisture removal through fluidization.

The fluid bed granulator integrates mixing, drying, coating, granulation, and other technologies, which are suitable for a variety of powders.

Case Study: Customized Coffee Processing Equipment Solutions Help Malaysian Coffee Brands Achieve Dual Upgrades in Quality and Efficiency

STT 150 tablet tube filling machine, specifically designed for packaging similar to effervescent tablets in straight tubes.

The SBF 260 bottle filling line, also known as the automated counting and packaging line, integrates bottle handling, feeding, counting, filling, and sealing into a seamless workflow.

The Blister Packaging Machine is used for packaging capsules, tablets, fudge, and other materials in pharmaceutical processes.

The STF 800 tube filling machine is a device specifically engineered for large-scale production industries. Compared to standard tube filling machines, it features a dual-station design.

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line