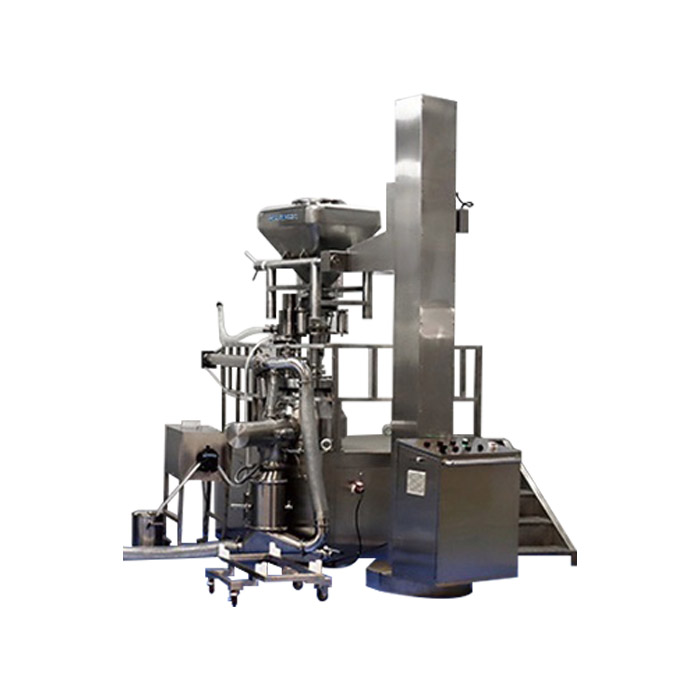

High Containment Rapid Mixer Granulator OEB 4/5 Features:

- It has a high blending and mixing speed

- use of organic solvents or only water

- OEB 5 Containment level

- The machine produces highly dense and less brittle tablets.

- It is designed to maintain health and safety according to norms of Current Good Manufacturing Practices (cGMP).

- A unique inline dispensing system to discharge granular powders, which optimizes granulation time

- Its mixing and grinding process is completely automated in one bowl

- The blending and granulation are accomplished in a short period with high precision and accuracy

High Containment OEB 4/5 High Shear Mixer Product Features:

Health concerns have also increased significantly with the medical industry and technology progress. Many toxic and hazardous compounds are used to process and produce various pharmaceutical products.

Senieer is fully aware of the adverse effects of OEB 5 compounds on the people’s health in the vicinity. Therefore, we have developed advanced, user-friendly, and environmentally friendly devices. Our uniquely designed High shear mixer provides efficient and uniform granulation of potentially dangerous compounds.

Our Rapid mixer granulators are designed to provide OEB 5 containment level. They are highly safe and health-friendly for the operator. We care for our staff and customers; therefore, we make sure that our products are according to the cGMP health and safety standards.

We also produce inline high shear mixers. Inline mixers feed and produce output in a continuous stream, allowing products to be perfectly homogenized and hydrated in a single pass.

Material is fed into the granulating bowl through a material feeding lifter. After this impeller, centrifugal force function and the spray gun injection provide pressure for the dosing system. The cutting knife rotates at high speed at the same time. The material is bonded into hollow particles in the pot body. After granulation in the granule machine, the material is transported through a vacuumed, air-tight pipeline to a fluid bed drier.

We have standard as well as customized models for high shear mixers. Our OEB 5 containment level RMGs are available in three models with uniquely designed features and structures.

Technical Details of Models:

| Model | Main Dimensions | Feeding Quantity (Kg/Batch) (Material Bulk Density 0.5 kg/L) | Impeller Power (kW) | Chopper Power (kW) | Milling Power (kW) | ||

| L | Y | W | |||||

| SRMG 100 | 2100 | 1650 | 2800 | 20-40 | 11 | 3 | 3 |

| SRMG 200 | 2600 | 1900 | 2950 | 40-80 | 18.5 | 3 | 4 |

| SRMG 300 | 3000 | 2090 | 3530 | 60-120 | 22 | 5.5 | 5.5 |

Senieer is recognized globally for its quality products and unique designs. Customer satisfaction is our top priority. Enlisted are some of the features of our high shear mixer series that make them most suitable for granulation and drying processes:

- The diameter and height ratio of the pot body makes the granules forming effect more uniform and enhances its reproducibility.

- The gap between the pot body and the stirring paddle is 1.5mm.

- The bottom of the pot has no material residue.

- The Inlet air control valve uses proportional adjustment.

- The endpoint determining system of granulation ensures the reliable reproducibility of granulation.

- An Integrated WIP system assures clean and no dead corners.

- It provides a high containment of over OEB 4 containment level.

- Its Feeding system has A/B valve docking.

- Wet granulation is equipped with a negative pressure exhaust system.

- The air exhausts through efficient filtration.

- All dynamic sealing systems adopt double sealing.

- Monitored sealing states

- It is equipped with power off and gas off protection measures.

- Optional explosion-proof design can provide Ex II B (explosive gas) and Exa21 /B21 combustible dust protection grade design.

- The machine is compliant with FDA/ cGMP production norms.

The machine can provide an anti-1 Obar detonation design according to the customers’ needs.

Machine manufacturing is a highly complex and competitive business that requires a high sense of responsibility. With our years of industry experience, we are equipped with the best technology and staff to ensure all the testing, sales, repair, and servicing requirements. Our team has the skills, knowledge, and tools to comply with all the OEB 5 compounds requirements.

Senieer being the worldwide supplier of pharmaceutical machinery understands the nature of responsibility it has and provides efficient, reliable, user-friendly, and eco-friendly machines. Our Rapid Mixer Granulator machine also has a unique high shear mixer and granulator technology, making it perfect and faultless to work effortlessly in almost every industry.

Contact us to learn more about our high shear mixer series and services and how they can benefit your pharmaceutical company.

CEO Note

Hey! This is Nikki. Thanks for visiting our website, and I hope we serve your needs meeting the international standards. We are pharmaceutical equipment and machine manufacturer with over 30 years of experience, and I would like to share with you our expertise in this field and answer any questions you may have about pharmaceutical machinery. I am always happy to help.