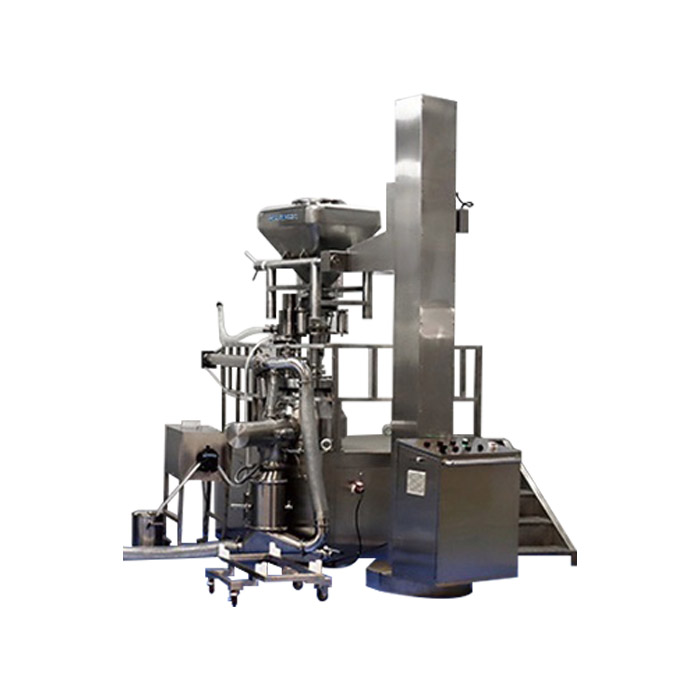

SRMG 300 High Containment OEB 4/5 High Shear Mixer Features:

- It produces highly dense granules.

- Compliant with CE and cGMP norms.

- OEB Containment Level 5.

- The gap between the pot body and the stirring paddle is 1.5mm.

- An integrated WIP system assures clean and no dead corners.

- High milling power of 5.5kW

- Chopper power of 5.5kW

- Feeding capacity of 60-120kg, suitable for medium-large scale production.

- Impressive impeller power of 22kW

SRMG 300 High Containment OEB 4/5 High Shear Mixer Description:

Senieer SRMG Series Rapid Mixer Granulators are multi-purpose high shear mixers for various material processes such as milling, drying, or granulation. It has a high-quality stainless-steel structure with advanced dust handling ability for effective OEB 5 drug containment. Our devices are compliant with the strict cGMP standards.

With a fully automatic system, Senieers SRMG 300 is suitable for large and industrial-scale processing of OEB 5 compounds. It has a feeding capacity ranging from 60 kgs to 120 kgs. With a high feeding capacity and impeller power of 22 kW, SRMG 300 is ideal for milling, granulation, and mixing in pharmaceutical, cosmetics, chemical and food industries. Senieer provides various configurations in the SRMG 300 model, depending upon process requirements, batch sizes, and layout concepts.

Material is fed into the granulating pot of the High shear Mixer head through a material feeding lifter. After this impeller, centrifugal force function and the spray gun injection provide pressure for the dosing system. The cutting knife rotates at high speed at the same time. The material containing OEB 5 Compounds is safely bonded into hollow particles in the pot body. After granulation in the high shear mixer, the material is transported through a vacuumed, air-tight pipeline to a fluid bed drier.

The Device has a chopper with a 5.5kW power motor along with a 5.5 kW Miller. High-speed blending impellers and choppers strengthen the chopping and blending of the raw materials. It also has Safety Guard rails to maintain a safe distance between the machine and the operator.

Senieer’s high shear mixers are used for material mixing and granulation. In the process of granulating, the material is shaped as the spray of the solution. Next, the rotatory impeller mixes, stir, and piles up the OEB 5 material to form granules of different sizes and shapes. The shaped material is then moved across the chopper and chopped into bulky grains.

SRMG 300 is specifically designed to keep operators and workers safe from the toxic fumes and contaminants of OEB 5 compounds. We are fully aware of the consequences of exposure to OEB 5 drugs. Therefore, we have designed our machines to maintain the health and safety of our clients.

Senieer is a prime pharmaceutical manufacturer. We do not compromise on the quality and integrity of our product. Our company is known for its trained and experienced experts. They strive to provide the highest possible level of OEB Containment to customers. We provide guiding manuals, tech support, and repair and cleaning services to our clients at the lowest possible costs.

If you want to know more about our SRMG 300 High shear mixer, contact us right away.

- Send Inquiry