Capsule Filler : Units and Features

- Embedded with a stainless steel frame.

- Safety precautions applied to an interlocking system.

- Advanced capsule and powder feeding parameters.

- An LCD touch-screen display.

- Adjustable weights and changeable parts.

- An automatic lubrication system.

- Vacuum system present.

- CE and cGMP compliance.

- Adjustable gap between the tamping plate and dosing disc.

- Sensors that detect the flow of materials

Senieer Is Worlds Leading Capsule Filler Manufacturer & Supplier

Capsule Filling Machine Or Encapsulation Machinery: Introduction

The pharmaceutical industry has to invest in different technologies for manufacturing different types of medications. A capsule machine is one of the most significant equipment because it produces a cylindrical-like medicine with round ends. It operates by filling hard or soft gelatin capsules with various substances which can either be pellets, powder, liquid, or suspension.

The capsule machine or Encapsulator machine has several parts which we shall discuss below. Furthermore, we shall explore some of its sub-products accompanied by its features. Small and large scale manufacturers benefit from this equipment significantly. At laboratories, you can utilize the machine’s unique parameters for research and development.

Capsule Filler: What is it?

A Capsule Filler is standard for pharmaceutical and industrial purposes. It is an electro system designed to fill soft or hard gelatin capsules with different substances in the form of granules, liquids, powder, and etcetera. Ideally, any material containing active pharmaceutical ingredients is ideal for this equipment. Professionals refer to the entire process as encapsulation. There exist three types of capsule machines which include manual, semi-automatic, and automatic capsule machines.

Capsule Filling Or EncapsulatorMachine: Working Principle

Some of the most common operating principles of a capsule machine include rectification which eliminates bad gelatin capsules. All the devices should also be able to separate capsule caps and dose them with different substances. They should also be capable of rejoining caps and ejecting filled capsules. So, if anyone asks you how capsule machines work, take them through the following steps. The first step includes placing the machine on a flat space. You then disassemble the capsules; that is, open them and make sure the short lids are on top while the longer ones are on the bottom facing upwards. The equipment then fills the empty caps with different materials and closed it. The entire process depends on the model and features. Some eliminate excess drug mixtures automatically while others require manual operation. Either way, the last step is to eject filled capsules.

Capsule Encapsulation Machinery: Parts and Working Principle

Most capsule filling machines or encapsulators have a 200-300 bed hole, a loading tray, a powder tray, and a pin plate. They also have a sealing rubber-cap-plate, a lever, and a cam handle. Let us discuss some of the most significant parts;

Capsule Hopper

This level-sensor-activated part (for automatic capsule filling machine) holds all the empty capsules you might want to fill. It comes in a cylindrical, cubic, or conical shape and we make it with stainless steel materials. You will come across a capsule hopper with two, level sensors placed on low and high levels respectively. These hoppers open and close automatically based on the filling process.

Capsule Feeding Unit

This part has a rotating wheel designed to be in constant motion as perfect capsules flow to the primary capsule hopper. A capsule feeding unit connects the main hopper through a vacuum loader. Ideally, the capsule feeding unit is found at the top of the machine as shown below;

Powder Hopper

This part comes with a screw feeding mechanism whereby a screw conveyor transfers powder from the hopper to the filling section. A Powder hopper accommodates the substance you feed into a capsule machine through the power port. It also has a level sensor that regulates the amount of power fed into the hopper.

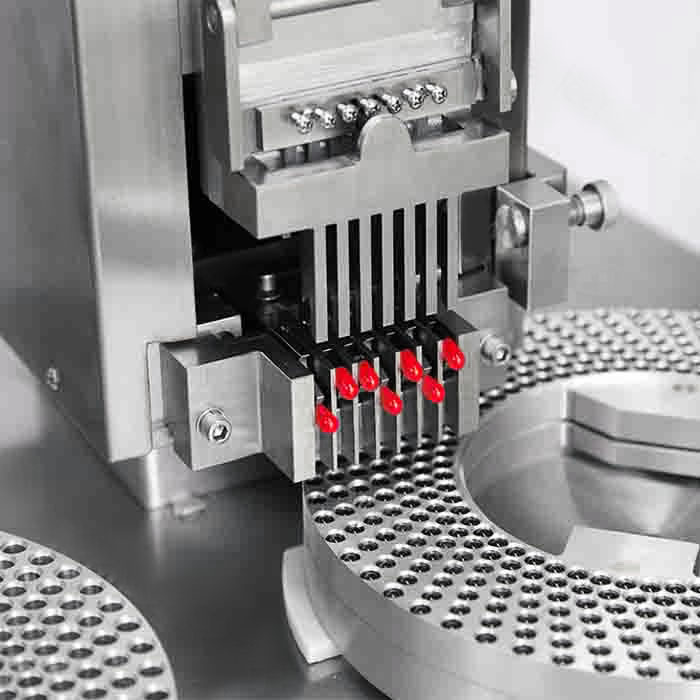

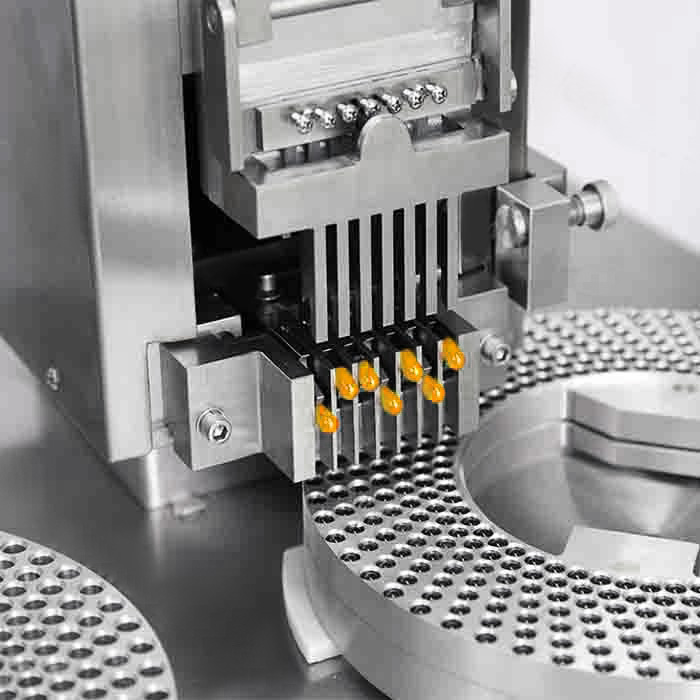

Powder Dosage Filling Device

The part plays a significant role in supplying a precise amount of powder into the filling parameters. It has a level sensor that regulates powder quantity from the hopper to the filling element automatically. Based on the size of the encapsulator, the filling process occurs when the powder held on the dosing disc becomes compresses by an air jet and released to the filling funnels. Note that some of the capsules filling machines have two power dosage devices.

Complete Closed Rotary Turret

This part allows the capsules to filter out excess powder and move to the block containing cups. The extra amount goes back to the hopper.

Mechanical Drive System

The part is designed to create a linear, rotary, or oscillatory motion. It harmonizes all the moving parameters in a capsule machine. We have the main drive, motor drive, and a vacuum pump.

Lubrication System

The presence of numerous moving parts calls for a reliable lubrication system. It prevents wear and tear of mechanical parts. Furthermore, it reduces friction during motion as well.

Vacuum System

This part connects the capsule loading panel to the capsule hopper as well as the powder loading part to the powder hopper. The vacuum system ensures capsules remain intact by separating empty capsules. A cleaning station is also available within the vacuum system.

PLC and Touch Screen Control Panel

This is a control interface that drives operations on command. It protects the capsule machine overload as well as running safety precautions. It carries intellectual instructions throughout the entire process.

Powder and Capsules Loading devices

The powder loading device provides consistency and accuracy by minimizing wastages and capsule rejection. The empty capsule loading parameter controls the capsule loading process. It has two or more loading plates ideal for small and large production.

Capsule Filling or Ecanpsulation Machine Manufacturers:

At Senieer, we only assemble the best technology for you and your business. Get your free quotation now, and we shall ship at your convenience. We ensure our clients do not miss out on the latest pharmaceutical devices in the market. Reach us for a series of high-tech capsule filling machines or encapsulation machines for your business.

Free consultation and Technical Support for Encapsulation Machine or Capsule Fillers:

Senieer provides all its esteemed customers with a free consultation and technical Support for Capsule filling machines. We guide you through the whole process of design, implementation, and operations of Capsule filling machines.

Why Global Companies Trust Senieer

Trust Senieer! Your Most Professional Partner

Hey! This is Nikki. Thanks for visiting our website, and I hope we serve your needs meeting the international standards. We are pharmaceutical equipment and machine manufacturer with over 30 years of experience, and I would like to share with you our expertise in this field and answer any questions you may have about pharmaceutical machinery. I am always happy to help.

We offer a wide variety of Capsule Filling Machines and offer free consultancy to many clients, and if you need any help even on any other pharmaceutical products, you are always welcome to reach out to me by sending your request below: