Vibro Sifter Machine

Ideal for separate and screen of granules, powder, semi liquid and solids Inlet hopper, inspection window, valve to control material outflow as option One deck, two decks, three decks or four decks as per your URS Easy cleaning and dismantling

Vibro Sifter Machine : Product Description

Senieer vibro sifter also called circular vibrating screen, the rotary vibrating screen is used to screen, separate, remove impurities and filter materials according to the particle size difference.

The vibro sifter is widely used in pharmaceutical, health product and food industries.

Details of Vibro Sifter Machine

- Wide range of screening: Any particle, powder, slurry can be screened. Sieving small to 500 mesh(28 micron),filtering small to 5 micron, can achieve efficient screening and filtering.

- Mesh anti-clogging: Three-D vibration function and design the automatic cleaning anti-clogging settings to minimize the chances of blocking screen.

- Single layer or multilayer sorting: You can select one to five screens, simultaneously sorting or filtering two to six grades.

- High efficiency accurate screening: All materials into the machine automatically emissions, no deposit material inside the machine. Sieving machine screen surface than other types of the same screen machines have a greater capacity.

- Screen convenient replacement: According to the different needs of a variety of screen grid structure. One of the replacement screen time down to 3-5 minutes. Screen longer life and higher efficiency.

- No mechanical vibration conduction: The three-dimensional vibration generated by the new vibration source is strong and steady. Equipment can be installed into any desired location and ease of movement.

- Economic and environmental: The machine and screen have a long life, low energy consumption, low maintenance costs, high efficiency, easy to replace and other features make the device affordable. Low noise, fully enclosed, outstanding environmental performance.

Sifting and rebolting: It is one of the key implementations in the distinct type of computing equipment. In this, the lumps eventually formed on the products after storaging for a long time.

Screening and scoring: It is an important function of the vibro sifter that applies in the processing of segregating the material as per the accurate dimensions. They include different kinds of properties to improve the speed of the process of screening.

Products are widely used in: pharmaceutical industry, health product industry, food industry, chemical synthesis industry, plastic industry, resin industry, Chinese and Western medicine industry, coating ceramic industry, metal powder mining industry, electronic magnetic material industry, paper industry, environmental protection industry, etc.

Custom design your layers according to your process requirement

High output, min noise and compact design

Energy saving

Contact product part SS316L or SS304 is available

Base part SS304 or carbon steel is available

Vibratory motion in the adjustable mode

Multiple screen variation

More Models of Vibro Sifter Machines

Single layer vibro sifter machine

Double layers vibro sifter machine

Three layers vibro sifter machine

Any Question About Senieer Vibro Sifter Machine

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize equipment for you

Equipment Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Equipment Training & Maintance Service

Free Equipment training & maintenance Service for you, we will provide your team in-depth training on safe operation and equipment maintenance

Equipment Installation Service

Senieer offers equipment installation & commissioning service for production products, your equipment and control systems are qualified based on the GAMP lifecycle

Vibro Sifter Machine Ultimate Buying Guide for Importers

Let’s dive right in:

- Chapter 1: What is a vibrio sifter machine?

- Chapter 2: How a Vibro Sifter Machine Works

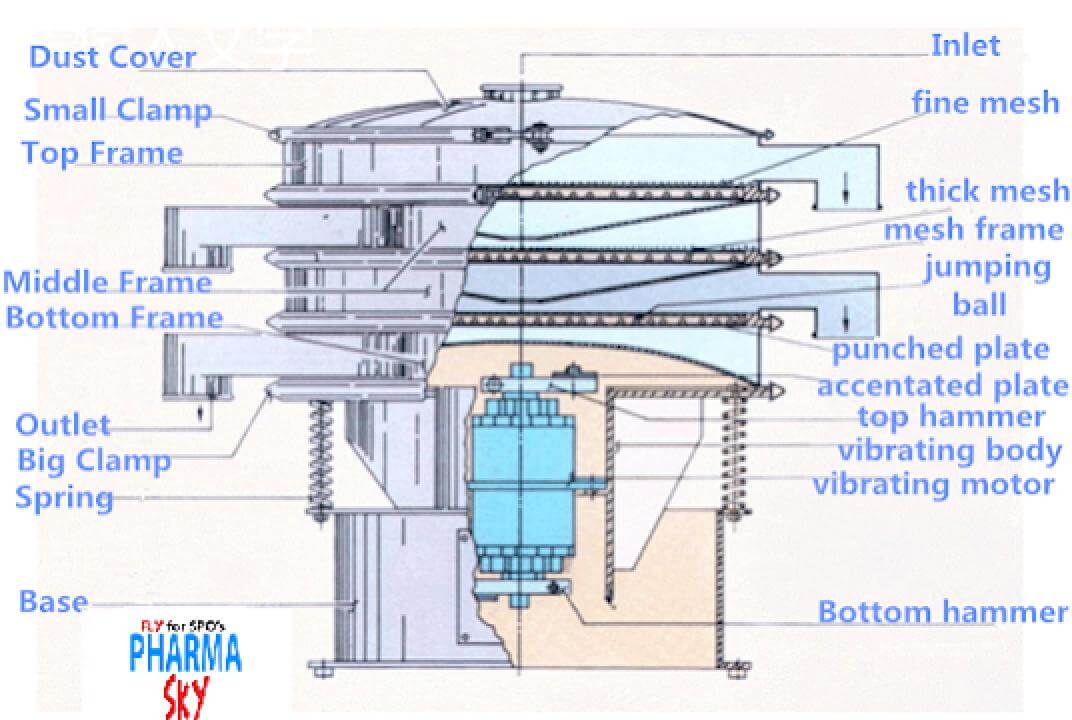

- Chapter 3: Main Parts and Components of a Vibro Sifter Machine

- Chapter 4: Main Uses of Vibro Sifter Machine in the Material Processing

- Chapter 5: Classifications and designs of Vibro Sifters

- Chapter 6: Types of Vibro Sifter Machines

- Chapter 7: Benefits of Vibro Sifter Machines

- Chapter 8: How to Choose Vibro Sifter Machine

- Chapter 9: Frequently Asked Questions About Vibro Sifter Machines

- Chapter 10: Conclusion

You will also get the right information with regards to choosing pharmaceutical bins manufacturers and suppliers.

Chapter 1: What is a vibrio sifter machine?

This is a vibrio sifter. It is used to separate vibrios that are smaller than 0.85 mm in size from larger vibrio particles. Vibro sifter has a vibrating screen surface that separates vibrios based on size and density.

The vibrio sifter machine basically has an electrically powered motor with steel balls as shaker or separator mechanism, vibrio motor, and vibro cell unit which creates vibration for separation purposes.

There are different vibrio sifter machines such as vibro permanent magnetic vibrio sifters or vibro separators which work by vibrating a separating surface at a very high rate.

Vibrio has a Greek origin and means “to vibrate.“ The vibration of the machine makes it possible to separate particles of different sizes

What is vibro sorting?

Vibro sorting refers to the process of separating vibrio smaller than 85 µm from vibrio above 85 mm in size. This technology was first invented by Dr. Arthur Haven at the University of Wisconsin – Madison, which has revolutionized many areas requiring sterile filtration such as blood products and vaccines production.

The basic principle behind vibrio sorting technology is that when vibrio passes through a vibro-sorter they are separated according to their vibratory amplitude; i.e., the smaller ones are entirely shunted while the larger ones pass through without any separation.

Chapter 2: How a Vibro Sifter Machine Works

A vibro sifter machine works by vibrating the material that is in mesh bags in which they are placed through a vibro sifter machine. The vibro sifter machine has a wide opening at one end that allows the vibro sifters to be inserted into the vibro sifter and then subjected to different vibrational frequencies by turning different gears on the vibro sifter machine.

There are 2 vibes, one large and heavy-duty for hard objects and two smaller ones. All of them have mesh bags inside of them where you place their contents (fill). Then those vibes are turned on using gears on the vibro sifter machine, which makes it vibrate at different frequencies. Some turn clockwise while others move counter-clockwise.

The vibes are placed on a vibrating machine and then the vibro sifter machine is plugged in with a VCR cord. Then you can start to adjust the different vibing speeds by turning different gears that have letters for vibing speeds, or you can choose to always have it set to one speed by just using the same gear until its content is sorted.

These vibers also have knobs adjustments for a higher range of frequency movement, which makes the vibro sifters go faster so that they sort quicker. An elaborate control panel will allow you to do all kinds of adjustments to the speed of sifting.

Some vibro sifter machines make it easier if they were to be turned manually (hand-held) instead of being vibed automatically using motors and gears on the vibro sifter machine. However, automatic vibro sifter machines are still preferred because they are faster and more efficient.

The vibro sifter machine has exit components that allow the sifted materials to exit through. From there you can collect the materials as they will be ready for the next production stage.

This working principle is also known as gyratory vibrations. Under this principle, particles are sifted and separated based on their size. In vibro sifter machines, the mixing of materials and their frequency allows for greater speed by which the vibes will sift at. This is called gyratory vibrations.

The materials being sorted in vibro sifters are kept inside mesh bags so that they are held intact while being subjected to vibes. These mesh bags also aid in separating finer particles, since finer particles tend to be lighter and so they will float above the vibro sifter machine as it vibrates.

Chapter 3: Main Parts and Components of a Vibro Sifter Machine

The main parts of the vibrating sifter machine include:

3.1 Vibratory electric motor:

This is the lifeline of a vibro sifter machine. It vibrates the cylinder that is used to move material from one end to the other and back to separate it based on differences in weight. This part makes all the difference between a successful sifting process and nothing happening at all!

The vibratory motor converts electrical energy into mechanical energy. This means that it is responsible for the vibrations that set the whole sifting process into motion.

Some vibro sifter models come equipped with larger motors than others. The horsepower rating is what determines how much power your machine has. The higher the number, the more powerful it will be and therefore, better suited for tougher jobs.

A lower horsepower won’t necessarily mean that you’re getting less quality vibro sifting; just that you’ll need a bigger capacity or more power for the work you’ll be doing.

3.2 Driveshaft:

This drives the vibrations that are responsible for processing material. It’s attached to an electric motor or a gas engine depending on what type of vibro sifter machine you have. Once connected, it moves back and forth according to how powerful its motor is. This makes it easy for particles to pass out of the vibrating head into the screen.

For additional options, you can choose from models which contain a centrifugal force of up to 1.5 T/m as well as models that allow for fine-tuning based on the rpm.

3.3. Vibrating head:

The vibrating head is what moves back and forth so that material eases through while being sifted. Vibration frequency varies depending on the machine model; there are those which go all the way up to 7000 times per hour.

This makes it easy to get rid of even finer particles. The headless shaft helps make vibration possible at a high frequency while also maintaining control over them. When choosing this part, consider its diameter and type since these will determine how much flexibility you’ll have for sifting different sizes of materials.

3.4 Filter screen:

This is another vital component of a vibro sifter machine. Its job is to trap the finest particles that come along with the material being sifted so that they don’t end up in your product.

A vibratory screen is what separates large particles from small particles. Due to this, they’re usually made of high-quality materials such as stainless steel or plastic.

While there are different types of screen filters available on the market, smooth wire mesh and nylon window screen are the most common types used in vibro sifter machine applications.

The size you choose should be based on specific parameters such as the type of material you’re working with and how fine or coarse it is. If the particle size is a major factor of concern for whatever reason, we recommend purchasing extra-fine meshes.

They have fibers that are closer together than what would be found on standard screens and allow finer bits to pass through whereas coarser particles remain inside.

The screen is held into its position by the tensional force. this makes it easy for the particles to pass through. You can also adjust the motion of the screen so that it gets in line with the performance of the motor.

It is also important to note that the screens for the vibro sifter must be FDA-approved. This is because the screen will be in contact with food products and therefore, must be safe for consumption.

3.5 Material Hopper:

The sifting process only begins once you load up material into the hopper of your vibro sifter machine. This part has a lid that helps keep it closed so that no unprocessed material comes out while the machine works its magic on what’s inside.

One way to make sure particles don’t pass through unnecessarily is to consider making use of an anti-flux shield that attaches to the hopper opening and prevents any foreign debris from entering. It makes sense to have it if there are other pieces around such as exhaust fans or fans used in industrial settings.

For safety reasons, don’t forget that an effective way to keep your employees safe while working with the vibro sifter machine is to have it installed on a reinforced platform.

3.6 Locking system:

This is another piece of equipment you might want to invest in if you’re using this system for industrial purposes. The locking mechanism secures the hopper’s lid to prevent any accidental contact or injury during operation.

It also helps maintain the best sifting performance and prevents material from moving around unnecessarily.

3.7 Cover/lid

The cover helps protect the vibro sifter machine and keep it in good condition. You should remember to secure the cover to the top of your hopper so that there are no unnecessary openings from which material can escape.

If you will be working with flour products, for example, you may want to consider an additional piece called a baghouse screen frame that can attach directly to the hopper opening. This is used when a more sophisticated filtration system is necessary; one with electronic sensors would be best as they provide automatic protection against overloads.

The cover also plays a role in preventing the contamination of the materials by any foreign material that could enter. For this reason, it’s best to use covers made of high-quality materials such as stainless steel. The higher the level of durability, the longer your vibro sifter machine will last for processing many batches.

3.8. Base and column:

These components are often available in a kit when you buy your machine. Depending on what you’ll be using its capacity for, consider whether or not you want to have casters installed on it; they make it easy to move around if necessary. In addition, this is another area where additional features can be added depending on the level of sophistication you want for your vibro sifter machine.

The base will keep the vibro sifter machine in place so that it can work efficiently while the column provides a system to support the upper mechanical components and connect them effectively. With this option, you also gain access to advanced vibration functions which allow for fine-tuning as well as agitator options.

3.9 Outer casing:

The outer casing provides stability for the vibro sifter machine by keeping its inner parts in place. They may be made of metals such as aluminum or carbon steel depending on how durable you need them to be while also providing electrical insulation.

When working with a more traditional vibratory screen, this part is usually painted black; this helps it absorb solar energy so that it doesn’t overheat during use. This is especially important if you’ll be using your machine outdoors without consistent shade cover.

3.10 Springs:

Springs are primarily responsible for keeping powerful vibrations in place so that material can pass through easily without becoming damaged. In most cases, you’ll find that the springs will be oil tempered; this ensures that they won’t lose their tension and shape over time.

3.11 Control panel:

A vibro sifter machine features a PLC control panel. These panels are known for their accuracy when it comes to controlling the vibration frequency and amplitude so that the material passing through remains in line with desired specifications.

They also feature a programmable logic controller which allows you to set up specific parameters for automatic operation over time as well as an easy-to-read display that shows information about the vibro sifter machine and its settings.

Chapter 4: Main Uses of Vibro Sifter Machine in the Material Processing

Let’s have a look at the main functions of a vibro sifter machine:

Sifting of the materials:

The sifting process entails the removal of lumps from the particles. These lumps are usually formed during the storage of the particles. The machine sifts or sieves materials by shaking it in a particular direction. The vibro sifter machine is widely used to separate the size of materials that have different granulation and sizes.

Smaller vibro sifters are largely used for sifting fine powder products like flour, pharmaceutical products such as pills, or sugar grains from the larger ones. They also help in removing the impurities present inside them that include dust, stone fragments, or other unwanted materials. On the other hand, bigger vibro sifters are usually used for separating soil particles on a large scale, and then again finer vibro sifters can be used to remove particles of 2mm size from larger grained materials as well.

Screening and grading materials:

Vibro screening machines are also used for the grading of materials. It is done by placing vibro sifters in a line or row. The grading vibro sifter machine then shakes the particles from larger to smaller ones so that the finer material can be collected at one place and in the same way, heavier lumps will gather somewhere else.

When it comes to screening, vibro sifters are very useful for removing fine fractions from large-sized grained material. A vibro sifter might be having a 1mm mesh size but it does not mean that it cannot pass 5cm grains. As we keep shaking the vibro sifter machine in different directions, it will allow the finest particles to pass through while large-sized ones will be retained inside the vibro sifter machine.

Scalping:

It is a process of vibro screening which involves the removal of fines from materials that can be used for recycling purposes. A vibro sifter machine will help us remove larger-sized particles or lumps from materials that are light and required to be separated.

In vibro scalping, vibro sifters work much like in vibro sizing. It chops up granules into small proportions so that the storage and transportation become more convenient as trucks have a comparatively lesser load to carry. Scalping saves on transportation costs too as sized down materials occupy less space than the original material size.

Proof sifting:

Vibro sifters are also used to separate the inferior quality material from good ones. This is what we call proof-sifting. For example, vibro vibro sifters in a flour mill are used to test whether the incoming material is wheat or not.

This is done by shaking the vibro sifter machine at different speeds and if the wheat particles move faster than chaffs then only that particular proportion will be separated from other materials so that they could be recycled for making animal feed or even good quality flour can be obtained through the material sizing process.

Some of these functions can be combined like scalping and grading for an efficient operation of vibratory sifter machines in any industrial sector.

Chapter 5: Classifications and designs of Vibro Sifters

Vibro sifter machines are categorized into different classes based on their physical designs and appearances. Some of the key design characteristics that are used for classifying these vibratory machines include:

The number of sieves:

Vibro sifters may be classified according to the number of sieves that they contain. They are mainly two-sieve vibro sifters, three vibro sift machines, and four vibro sifters.

Inclination angle:

Vibro sifters can also be categorized based on the inclination angle at which the plates are hung from a vibrating driver. Machines with an inclination angle of 20°C have been shown to have optimal removal efficiency for coarse particles in comparison to those machines with an inclination rate of 40°C.

However, vibro machines with a 30°C inclination angle are easier to operate than the former ones as well as occupy low floor space thereby improving productivity.

Some vibro sifters have an inclination angle of 20°C, others 30°C and vibro shakers while others often have an inclination angle of 40°C.

The speed or revolutions per minute (RPM) at which the machines are driven:

The operating frequency to drive the machine can affect the performance parameters of the vibro sifter machines. Higher operating frequencies produce greater vibration amplitudes, hence more intense particle agitation leading to increased removal efficiency.

However, excessive vibrations could lead to a breakdown of vital components within the electric motor that drives them resulting in reduced lifespans and vibro sifter efficiency.

The vibro sifter shaker speed or frequency is usually expressed in terms of RPMs. The vibro shaker machines are driven with an operating speed between 35 and 40 Hz (revolutions per minute).

However, vibro machines like vibro sifters can also be driven at frequencies as low as 20 Hz or less depending on the application requirements while vibro filters can operate with higher frequencies between 80 and 100 Hz.

Area of application:

Vibro sifters are usually categorized depending on their specific areas of application. Some sifters are used for major industrial applications while others are used in labs for research purposes. The design characteristics of these vibro sifter machines will vary.

Type of drive system

The vibrating drivers that power these vibro sifting machines can be identified based on their layout characteristics. Some drivers consist of a main transverse shaft while others have cross-shafts mounted on base pad plates with driver arms positioned above them.

General design:

Vibro sifters may also be classified according to their general designs. Vibro sifter machines can be designed as either single vibro sifters with a trapezoidal or rectangular design and vibro shakers that feature a cylindrical frame while others have a spherical-shaped housing.

Chapter 6: Types of Vibro Sifter Machines

There are different types of vibro sifter in pharma. Let’s look at some of these types and their key features.

6.1 One-layer vibro sifter

This is the simplest type of sifter. It consists of a vibrating sieve plate, which is separated from the product by a layer of air. This style has been known as *single-layer vibro shaker.

The bottom layer designates the actual vibration part, while the top layer can be made up of various types of materials. Different types of materials are used for different types of pharmaceutical powders or granules that require to be sifted and they vary in weight and thickness.

The single-layer vibro shaker provides higher speed shaking power than any other type because there are no obstructions present between the product and moving parts in this machine.

Due to its high amount of vibrations per minute (VPM), this one of the types provides a higher sifting speed than others. This is an advantage over other types such as Double-layer Vibro Sifter or Triple-layer Vibro Sifter that vibrates much less, owing to their presence of 2-3 layers between the product and moving parts.

This type is mostly used for lightweight powders where there is no need for high separation efficiency, but only a faster sifting rate is required.

6.2 Double-layer vibro sifter

The double-layer vibro sifter consists of two types of plates, one top and bottom plate analogous to single-layer types. This is a very simple but effective type that doesn’t have major design differences from the single-layer types.

6.3 Triple-layer Vibro Sifter

The types consist of three types of plates, two top layers, and a bottom plate. The bottom and top layers are usually made from aluminum or steel with the weight varying depending on the application.

Also, there is an intermediate mesh layer present which separates the product from vibrating layers in between. This type has been known as triple-layer vibro sifter machine or triple-decker vibro sifters for making its manufacturing easy incorporating multiple types of materials to separate different types of powder having almost similar density levels.

6.4 Industrial vibro sifter

On the other side, industrial types of vibro sifters have become an indispensable part of any pharmaceutical and food processing factory. These types usually provide high separation efficiency along with higher capacity compared to other types.

The capacity level is indirectly proportional to the amount of shaking power provided by a machine. These types are quite expensive in comparison with other types, mainly because they consist of many vibration layers which make them heavier in weight than others.

They are used in large-scale production and for applications where particles need highly efficient separation as well as controlling their quality specifications based on customer requirements or company quality standards.

6.5 L-shaped sieve vibro sifter

As types of vibro sifters are used for various types of powders, they may differ in application and types. For instance, an L-shaped vibro sifter is an example of a type that removes all types of solids from dried milk or any other commodity as it has a large capacity to separate numerous types of particles at one time.

It is also very useful in separating liquid products from gas or steam-based products such as canned foods, fruits, and veggies, etc. The product is separated according to density level by the layers made up of different types of materials.

This type incorporates two vibrating decks that usually support each other along with the vibrating parts present at their bottom through the middle layer consisting of mesh structure below these top decks.

This middle part is known as a sieve or screen and its thickness is based on the types of material being separated by it. The types of vibro sifters are used in several types of industries such as food & beverage, pharmaceuticals, chemicals, fertilizers, etc.

Chapter 7: Benefits of Vibro Sifter Machines

Since we have already seen the uses of vibro sifters, let’s have a look at the key benefits that you can gain from using Senieer vibro sifters:

Quality sifting: Vibro sifters provide excellent screening performance, which helps remove dust or foreign particles from the desired aggregate

Fast separator: Since vibro sifters use vibrations to screen out aggregates, and not centrifugal force like other screening machines, vibro sifters work slower than other materials separating machinery. This makes them ideal for applications that require low throughput rates (which is usually easily achievable when dealing with small tonnage at a time) while still obtaining high-quality output.

Automation friendly: As we’ve seen earlier in this article, the advantage of using vibration-based screens for separation is that they are friendly to automation. Other machines which use centrifugal force, such as other vibratory sifters or cyclones, require more space within the machine in order for materials to flow through the screen and be separated.

Versatile; easily customized: Senieer vibro sifter machines provide excellent screening performance from only using basic components, making them highly versatile. This also means that you can easily customize these machines by adding additional features such as vibrating feeders or blowers if needed for your application!

Wide range of applications: The machines can be used on different materials and in different industries. For example, you can find vibro sifters in various types of manufacturing processes for screening out dust and other particles from aggregate material before it is processed.

Portable design: many vibro sifters are built with a lightweight aluminum structure, so they are easy to move around and set up in different locations. The design also makes it easy to handle and use.

No risk of dust explosions: unlike air or centrifugal force separation machines (like cyclones), Senieer vibro sifter machines have no risk of dust explosion due to the lack of pressure within the machine. This helps you eliminate possible safety hazards associated with working with other material separating machinery!

Energy-efficient: vibro sifters are also very energy efficient, and this makes them great for reducing costs of production. You will incur minimum expenses when it comes to dealing with the cost of energy.

It doesn’t matter which Senieer model you’ll choose; all of them come with advantages that will help you achieve your desired goals for any application you have!

Chapter 8: How to Choose Vibro Sifter Machine

Here are the key factors to consider when buying a vibro sifter machine:

8.1 . What are you going to use the sifter for?

Before buying a vibro sifter, one should first consider what purpose the device will be used for. For instance, some screening applications include cleaning, separating, classifying, and grading materials by particle size.

Some vibrating screens can perform multiple functions such as deagglomeration (removal of clumps), drying or washing products, etc.The majority of these types of screening applications require material sizes ranging from less than 1 mm to 50 mm and more; whereas others need only specific sizes. Your application is key to determining the capacity and specifications of your vibro sifter.

8.2 Are there any regulatory requirements pertaining to your vibro sifter machine

In certain applications, what you are working with may have specific restrictions or rules governing its use. Products being processed through a vibrating screen may be subject to federal guidelines that dictate how the product should be handled; these include but are not limited to food processing plants (FDA, USDA), pharmaceuticals, and medical equipment manufacturing plants.

For example, if you plan on using vibro sifters to handle pharmaceutical products like pills, drugs, etc. you will need vibro sifters that meet all regulations governing such materials as stipulated by the US Food and Drug Administration (FDA).

Regulatory agencies have to ensure that products like food, drugs, medical equipment, and accessories meet required standards for public health and safety; this is a necessary step in protecting consumers from contaminated or dangerous materials.

8.3. Size and dimensions of particles to be separated

In industrial vibratory sifters, size plays an important role in separating materials. Materials such as pharmaceutical grains and granules need to be sifted through small-size screens which have openings between 0.02 mm and 4.0 mm.

This shows that the size and dimensions of particles will determine the size of the screen that should be used for separation.

8.4. What are you going to use it for?

As mentioned earlier vibro sifters are used in a wide variety of applications from pharmaceuticals to food processing plants. Vibrating screening machines are ideal for separating fine, dry particles from other materials (like flour, dust, and dirt) to create a finer grade of material.

Vibro sifter machines are also used in chemical manufacturing facilities; these types of vibro sifters are called vibratory concentrate grinders or VCG’s. There are three different types of VCG’s available on the market today, each designed to meet specific processing needs.

8.5 Machine capacity per batch

The amount of material to be processed within a given amount of time) is also an important consideration when choosing a vibro sifter. For example, if you plan on buying vibro sifters for use in a pharmaceutical company, you will need industrial vibrating screen machines with a larger capacity per batch to meet the production needs set forth by your company. The capacity of the vibro sifter should be high enough so it can adequately handle the amount of material that needs to be processed within a given period for your company’s production to be efficient.

8.6. Vibro sifter Control features

Vibro sifters come with a variety of control features – some have controls that are separate from the vibrator motor, allowing you to set them at different speeds and levels of vibration.

Other models have remotes that can be attached to your vibro sifter and allow for easy control while it is being used. Additionally, many vibro sifting machines offer automatic shut-off options if they become overloaded or need servicing.

8.7 Your budget/Vibro sifter price

Vibrating screener machines range in price, depending on the features and specifications as well as size. You can expect to pay anywhere from $10k-$150k for a vibrating sifter. If you are looking for powerful industrial vibro sifters that will handle large amounts of material or if you want to purchase multiple machines, your budget could reach the millions.

These high-capacity vibro sifting equipment units come with unique features such as automatic controls, remote control capability, and overload protection mechanisms; they are designed to meet special requirements (such as processing pharmaceuticals).

8.8 Vibro sifter machine manufacturers

It is important to consider where you buy the vibro sifter machine. You should buy your industrial vibrating screen machine directly from the manufacturer of high quality and durable equipment.

You want to be sure you get a company that offers after-sales service, support, and warranties for their products.

Chapter 9: Frequently Asked Questions About Vibro Sifter Machines

Which industries use vibro sifter machines?

Some of the industries that utilize the vibrating sifting equipment include;

- Pharmaceutical

- Food and beverage

- Chemical production

- mining industry, etc.

There are numerous applications for vibro sifter machines. Commonly in industries like pharmaceuticals sifting is used to remove foreign particles from samples that need to be further analyzed & tested.

Sifters can also be used in food and beverage industries for removing unwanted materials such as dyes out of juices or syrups · The sifter machines can also be used in the chemical production industry for extracting chemicals that will be processed later into different materials or compounds.

What are the limitations of vibro sifter?

The main disadvantage is that the vibration sifting machine uses a lot of power and can be very expensive to operate especially when used for extended periods · Vibration sifters are mainly designed for fine powders, however, some models can also have a large capacity with coarse powders ·

When using vibratory screens it takes time before you start seeing results, because the material is being sifted from coarse particles to medium ones until eventually only fine powder remains.

How to choose a suitable mesh screen for a vibro sifter?

There are some factors to consider when choosing a suitable mesh screen for the sifter machine. The following are major considerations:

-Mesh Opening Size (EP) commonly referred to as European Polyester, refers to the size of holes in your sifting screen. – Commonly used range is 0.5 mm through 50 mm ·

-Fiber Length Generally available in 2mm, 3mm & 6mm ·

-Thickness. Commonly available in gage numbers 1, 1/16″ and 1/8″ ·

-Exterior Material. This will affect how much weight can be supported by the vibro sifters machine that you’ll be using with it and also its durability.

How can I improve vibro sifter performance?

Some considerations to improve vibro sifter performance include:

-Using the correct EP (European Polyester) Mesh Opening Size that suits your application

-Using enough power for your vibratory machine, if too little you won’t be able to move particles out correctly and also it might damage the equipment ·

Also, make sure when choosing a sifting screen with a fiber length of 3mm or more that they are not getting clogged up by fine rock and other material · Commonly screeners with a 9″ diameter design is best suited for larger pits or tanks.

What is the difference between vibro sifter and mechanical sifter?

Vibro sifters and mechanical sifter machines are basically for the same purpose, to improve the separation of solid particles from a combination of different materials. The main difference is that vibratory equipment will normally have a finer mesh design than mechanical ones.

Why is sifting important in the pharmaceutical industry?

It’s used to remove undesirable materials as well as different stages of the separation process. Common final products for tablets and capsules are processed through vibration screens which separate it from additives, binders or dilution liquid ·

Commonly vibratory equipment is also used for removing large amounts of product sediments so that customer gets a more refined product · –

Sometimes they’re used for cutting down on cross-contamination of components during the manufacturing process where certain raw materials can contain dangerous chemicals.

How does vibro sifter for pharma preserve high hygiene?

Vibratory sifters are commonly used in the pharmaceutical industry and food processing plants to save time and improve hygiene. Commonly the material will pass through a vibrating screen which both separates it from different components as well as removes unwanted materials such as fine silts.

Commonly the material is then passed on for packaging immediately after, this allows companies to maintain high hygiene standards by packaging products before cross-contamination has taken place.

The presence of the lid also helps to maintain hygiene standards by preventing dust and particles from escaping during production. Commonly the lid has gaps that allow for air to flow in and out while the material is being sifted.

Chapter 10: Conclusion

In conclusion, I hope that you have gained adequate knowledge about the vibro sifter machine. I know that this machine is a very important role in the food industry. Because of its function, it can help the manufacturer produce product with high quality and low production costs. I am sure that knowledge about vibro sifters will be very helpful to you to do your job well as a vibrating sifter.

If you want to get more information about vibro sifter or vibration screen, please don’t hesitate to contact us. We are a reliable supplier of vibration sifter machines in China. We mainly offer vibrating screens, vibration feeders, and washing machines. Our products are sold all over the world.