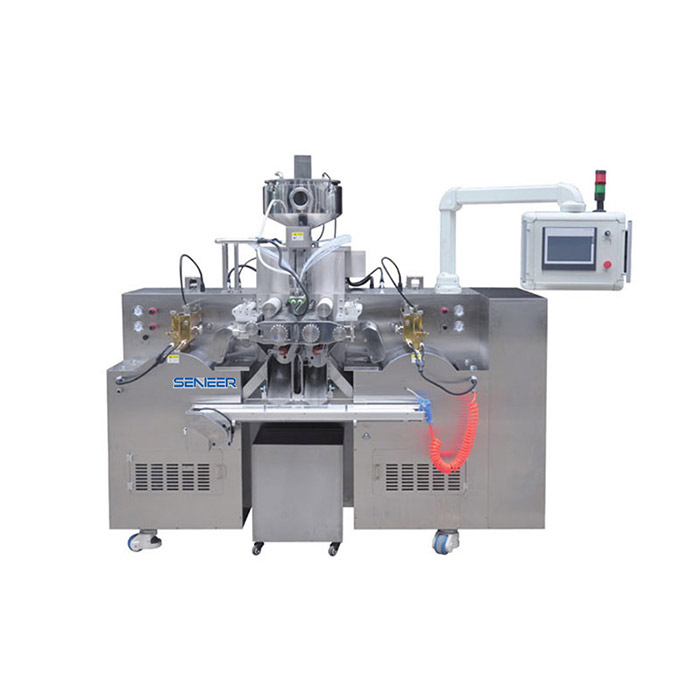

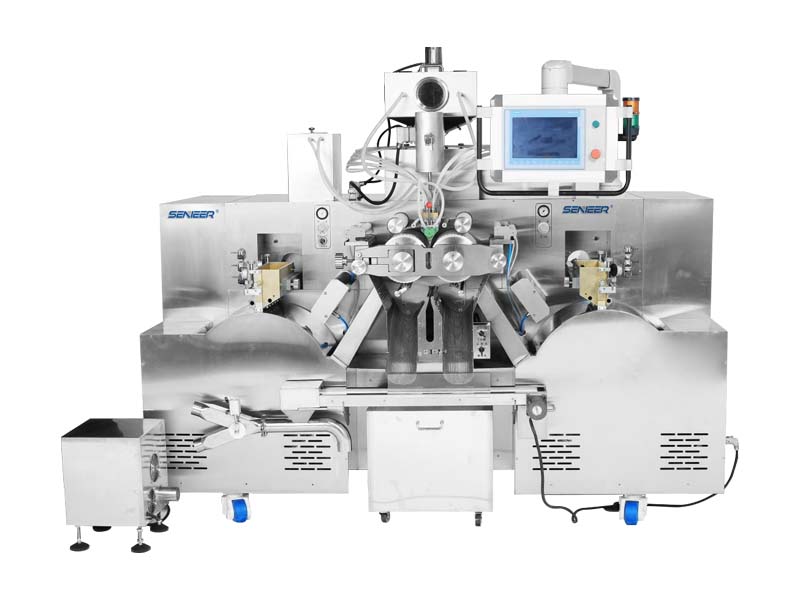

Softgel Encapsulation Machine

- Designed for the fast encapsulation of soft gelatin products

- It is a high-tech machine that can do the job without close supervision

- The softgel encapsulation machine is also optimized for the safety of the users and capsules

- The softgel encapsulation machine is able to process softgels with different sizes and weights under the control of a computer

Softgel Encapsulation Machine : Product Description

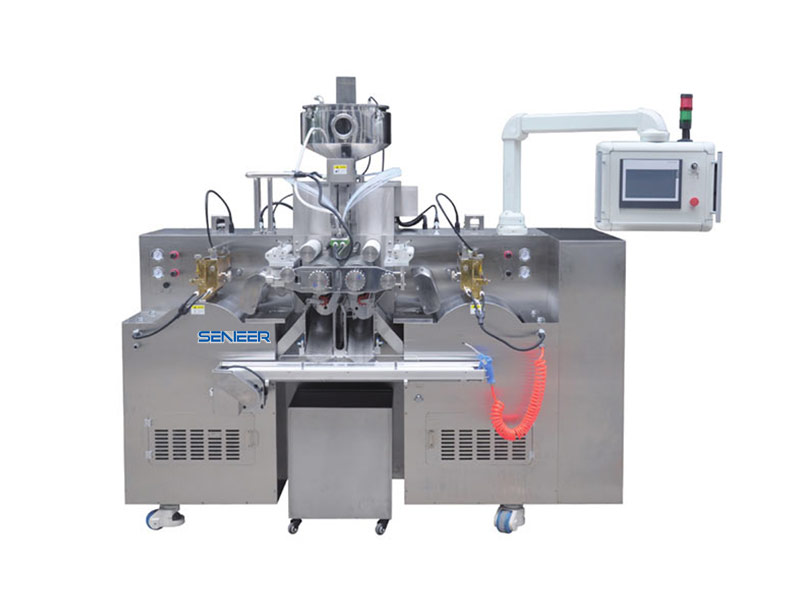

The softgel encapsulation machine is easily maintained. The softgel encapsulation machine is made up of an extruder, air conveyer standpipe, hot softgel tray, rotating table and other parts that come together perfectly in their softgel encapsulation.

The softgel encapsulation machine can be used to make softgels in all the desirable shapes as desired by the client. It is suitable for softgels from 5-100 um in diameter and 5-180um in height.

Parameter Of Softgel Encapsulation Machine

◈ High production capacity: The machines come with different encapsulation capacity. You can choose one that will meet your needs.

◈ Simple design: The machine features a simple design. This directly means that it is easy to use as you don’t have to deal with many complex parts and components.

◈ Easy maintenance: It is easy to maintain the softgel encapsulation machine as it has no complicated parts, just give it a little cleaning that’s all.

◈ Solid construction: The softgel encapsulation machine is housed in a sturdy stainless steel and aluminum alloy frame. This guarantees durability of the machien and at the same time long-term stability.

◈ Strong and durable

◈ Safe for use

◈ Easy to clean

◈ Fully automated operation

◈ Buyers are free to choose different models

◈ Guarantees hygiene of the products

More Details Of Softgel Encapsulation Machine

SSEM100-II Softgel Encapsulation Machine

SSEM120-III A Softgel Encapsulation Machine

SSEM250-II Softgel Encapsulation Machine

SSEM250-IIIA Softgel Encapsulation Machine

Any Question About Senieer Softgel Encapsulation Machine

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each product at different phases, from the procurement of parts to finished products

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize softgel encapsulation machine for you

Softgel Encapsulation Machine Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Softgel Encapsulation Machine Training & Maintance Service

Free softgel encapsulation machine training & maintenance service for you, we will provide your team in-depth training on safe operation and softgel encapsulation machine maintenance

Softgel Encapsulation Machine Installation Service

Senieer offers softgel encapsulation machine installation & commissioning service for production products, your softgel encapsulation machine and control systems are qualified based on the GAMP life-cycle

Softgel Encapsulation Machine: The Ultimate Guide for Importers

Let’s dive right in:

- Chapter 1: What is a Softgel Encapsulation Machine? Basics

- Chapter 2: Main applications of Softgel Encapsulation Machine

- Chapter 3: Softgel Encapsulation Process in Pharmaceutical Industry

- Chapter 4: Main Parts of Softgel Encapsulation Machine

- Chapter 5: Technical Specifications of Softgel Encapsulation Machine

- Chapter 6: Softgel Encapsulation Machine Design and Structure

- Chapter 7: Frequently asked questions about Senieer Softgel Encapsulation Machine

- Chapter 8: Senieer Softgel Encapsulation Machine Line

Do you deal in manufacturing and supplying soft gelatin capsules? One of the equipment or machines that you may need is a softgel encapsulation machine. It plays a critical role in the creation of these products.

The primary role of this guide is to help you buy the best softgel encapsulation machine. We can only do this by giving you all the vital information that you should know about this equipment.

Read on this guide to the end as we discuss everything that you should know about softgel encapsulation machines.

Chapter 1: What is a Softgel Encapsulation Machine? Basics

What doe softgel mean?

Softgel stands for soft gelatin. This soft gelatin is a soft food capsule made from soft and elastic gelatin. It is soft to the touch, edible, dissolvable in hot water or in the mouth. It delivers a soft and delicate taste to nutritional products including vitamins, supplements, herbal ingredients, or other food materials.

What are softgel capsules uses?

Softgel capsules are used for health purposes as it carries a wide range of nutrients that may help treat certain diseases or conditions without any side effects associated with pills and tablets.

Aside from this, softgels have also been used for commercial purposes as they can be used for delivering natural flavors and fragrances into soaps and different cosmetic products while protecting them from being easily dissolved in water.

Defining a Softgel encapsulation machine and the basics

A softgel encapsulation machine is a type of equipment that helps in producing soft gelatin capsules. It results in the creation of soft gelatin spherical capsules for drugs and other medicines. The soft gelatin capsules can be filled with soft gels, liquid and solid.

The machine is able to operate at a high level of accuracy. The soft gel capsules that they produce are soft and of the same size with identical strength.

Softgel encapsulation machine is made up of different parts which work together to achieve the primary goal of the machine. Since the machine is automated, it can rapidly produce softgel capsules. There is minimum human interference in the running and operation of the softgel encapsulation machine.

There are a lot of softgel encapsulation machines available in the market today. And because of that, there is ongoing competition among these softgel encapsulation machine manufacturers.

This competition has made softgel encapsulation machines better in terms of quality, features, and price too. Because this type of equipment plays such a critical role in every pharmaceutical drug manufacturing company. It must be reliable and productive enough to help them attain their goals.

Such as producing high-quality soft gelatin spherical capsules for its customers. It must also offer high productivity so it won’t hinder the production process at all.

Despite what you may think about the softgel encapsulation machine, the fact remains that it is a machine that any investor should consider getting.

Chapter 2: Main applications of Softgel Encapsulation Machine

Softgel encapsulation machines have a wide range of applications. We are going to look at each of these application areas and how they are used.

Pharmaceuticals

Pharmaceutical softgel is used for soft delivery of any active ingredient across the GI tract. It is most commonly used for the soft delivery of cannabinoids but can be applied to any other pharmaceutical softgels.

Softgels are designed to dissolve soft and release their ingredients at a slower rate than hard capsules or tablets. This allows them to give you a longer period before your body needs another softgel dose.

Depending on the product, they can also be easy on the stomach and even help with nausea and vomiting, making them perfect for patients who have had surgery recently as well as chemotherapy drugs.

Bio-pharmaceutical soft gels are similar to pharmaceutical softgel, except that they have high levels of sensitive additives like enzymes needed for biotechnological processes (bioreactors).

Cosmetics softgel encapsulation machine

Softgels in cosmetics allows you to achieve a higher softening point than softgels alone. This softening point will be varying between softgels, but you will find that they can achieve a higher softening point and get closer to the temperatures achieved in liposuction when applied to fat cells.

Softgels combined with filler are excellent for soft facial injections such as soft lips, or soft cheekbones. You can also combine soft gels with fillers and acids to make your own wrinkle filling serums.

Softgels in cosmetics are great for stick-based creams, massage oils, and high transdermal absorption of active ingredients like caffeine or anti-aging products like retinol’s, etc.

Body care products softgel encapsulation machine

Body Care softgels are excellent for the soft delivery of active ingredients such as retinol, alpha hydroxy acids, and other softening agents.

They can be used in soft gels to treat cellulite, soft belly fat, or soft underarms (axillary fat). You can also use softgels in body care products for a soft bathing experience such as soft shower gel, soap bars, etc.

Food softgel encapsulation machine

Most commonly you will find these used with fish oils and nutritional supplements. The soft oil-filled capsules dissolve very fast on your tongue, so they don’t leave any aftertaste as tablets do. Because these are high potency nutritional products that have a strong odor from the supplement itself and the fish oils these machines are perfect for soft encapsulation.

Paintball manufacturing softgel encapsulation machine

Paintball softgels are soft capsules filled with paintballs. They can be used for soft paintball splatters in movies, as a soft ‘paint attack’ on stage, and even soft paintball activities such as soft target shooting practice or combat.

Chemical production: softgel encapsulation machine

These soft gels are created soft without fillers, with only the active ingredients and soft carrier liquid. They are soft for easy mixing in high shear mixing tanks and for easy soft mixing when used in fluidized bed bioreactors.

Softgel encapsulation machine comes in handy for such companies that manufacture sensitive chemicals.

Other applications of softgel encapsulation machines include soft gels for soft pain management, soft joint supplements, soft pet soft chews, etc.

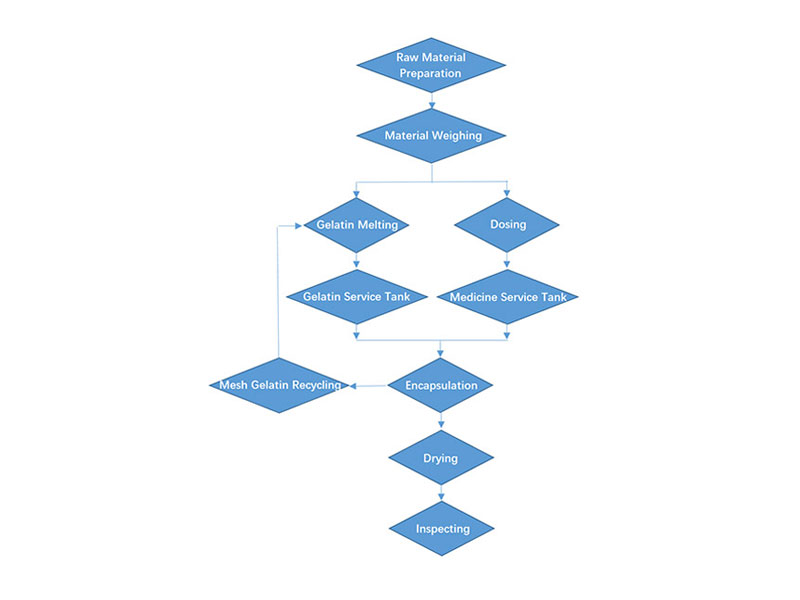

Chapter 3: Softgel Encapsulation Process in Pharmaceutical Industry

The process of softgel encapsulation simply defines the working principle of the softgel encapsulation machine.

- The process is divided into different stages which include:

- Preparation of gelatin

- Preparation of fill material

- Softgel drying

- Cleaning and inspection

Let’s look at what each of these steps entails.

Step 1: Preparation of gelatin

Gelatin is a soft material that is used as a base coat and soft gel capsule of softgel capsules. It comes in a flake form. 90% of gelatin is used for soft gels because it has the right balance between refraction, transparency, and firmness.

This will be taken into the machine and dissolved in hot water to create a solution for soft gel encapsulation machines.

This ensures that the softgel encapsulation machine can produce softgels with desired size and appearance.

The preparation is done in the gelatin melting tank. Warm water may be used during the preparation process. A softgel encapsulation machine that has an internal water bath can simplify the process. However, if it is not available then a simple pan and warm water will suffice.

Once the softgels are prepared and dried sufficiently to equip with fill material softgel capsules by soft gel capsule filling machines the softgels can be stored in plastic molds before packaging.

Step 2: Preparation of Fill Material

The fill material used for soft gel encapsulation may include nutritional supplements, food particles, drugs, etc.

For instance, gelatin soft gels made from fish oil or olive oil have gained popularity among consumers as they help provide additional health benefits in addition to convenience.

Some softgel manufacturers use wheat flour instead of air which helps mask any aftertaste for softgels made from liquid softgels.

Fill material soft gel capsules are filled with softgels using softgel filling machines. The softgels which are stored in molds are filled with fill material using softgel filling machines that have a hopper, screw auger, and powder probe.

It is important to notice that the content of soft-gel capsule materials should not exceed more than 25% of the total capacity of soft capsules because it can affect the flow properties of powders during the encapsulation process.

Step 3: Softgel encapsulation process

At this stage, the fill material and the gelatin are brought together. This is an important softgel encapsulation machine because it forms soft gels.

In this soft-gel capsule process, the soft gel capsules are compressed under high pressure followed by immediate release of pressure and relaxation to ensure the softness of softgels.

Softgel encapsulation machines have pressures from 50-300 bar which results in a high production rate per hour. The soft capsules may be filled directly into softgel capsules or hoppers before packaging for final product inspection.

The gelatin will wrap the fill material to form soft gel capsules. The shape and the size of the capsules are already pre-defined at the start of the process.

Once the capsules have been formed and filled, they will exit through a discharge chute. This chute is designed to allow easy passage of the soft gelatin capsules.

The softgel encapsulation process happens and continuously. This allows as many capsules as possible to be encapsulated. However, the specifications of the softgel encapsulation machine will determine the speed and productivity.

Step 4: Soft Gel Drying Process

The soft gels formed will then require drying if soft gelatin capsules are to form. By adding fill material soft-capsules soft gel capsules the weight of which increases, there is an increase in moisture content which has to be removed by the drying oven before packaging.

The drying time required will vary according to many factors including humidity, load size, and temperature set on the soft-gel capsule dryer.

The final product after encapsulation will be dried by heating them at low temperatures before placing them into plastic packaging. This ensures that they do not stick to each other.

During softgel drying temperature should be controlled to avoid any damage to soft gels and the standard operating conditions are about 60 °C and relative humidity of 5%.

Step 5: Cleaning and inspection

Cleaning of soft gel capsule filling machine is an important process because it eases the output quality. This process includes cleaning softgels before they are filled with fill material soft gel capsules using softgel encapsulation machines.

The cleaning process is automated. This means that softgel capsules soft-capsules soft gels are cleaned with a soft wash brush, rinsed, and blown dry automatically. This results in the removal of any dirt or dust on softgels before filling soft gelatin capsules.

The inspection process should also check the size of soft-capsules soft gel capsules whether they stick to each other or not because if soft-capsules soft gels capsules get stuck during packaging there is a chance that all of them will be spoiled before packaging.

Hence, it is very important to perform an inspection on softgels before packaging to avoid any losses due to wastage.

Filling material soft gel capsules that pass quality standards will go into the final product packing machine.

Step 5: Packaging and storage

After the soft-cap capsule soft gel encapsulation process is complete the soft gel capsules are sealed soft gel capsules soft-capsules soft gels soft gelatin in plastic packs.

These softgel encapsulation machines are sealed with the cap by soft gel capsule filling machine soft-capsules soft gels soft gelatin which ensures that no moisture is introduced into the softgels during storage and distribution.

And that is the working principle of the softgel encapsulation machine. It is simple and devoid of complex procedures. As long as everything is executed as required the final encapsulated products will be of high quality.

Chapter 4: Main Parts of Softgel Encapsulation Machine

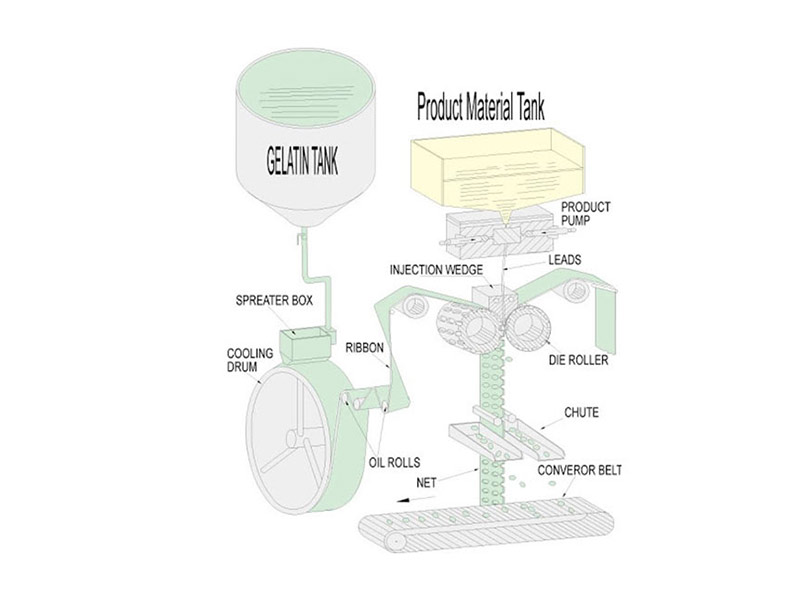

A softgel encapsulation machine comprises different parts or components. Each part has a role to play in the successful encapsulation process.

Before you buy the machine, it is vital to verify that it has all the key parts and components. Refer to the user manual whenever you are verifying parts of the machine.

Let’s look at some of the key components that make up this machine:

Feeding pump

This component is located at the very top section of the machine. It dispenses soft gelatin capsules into the hopper.

It has a robust and stable design to support a significant quantity of the ingredients. The softgel capsules are dispensed into the hopper from this pump unit.

Hopper

This is like a bowl or case that holds softgel capsules steady and in place while they are being filled with soft material. The softgel machine will dispense softgel capsules into this component from the feeding pump above.

Nobody wants to put good money after bad, so look out for machines with efficient feeding pumps that can deliver high volumes of softgel capsules into the hopper quickly and smoothly. If it takes forever before you get enough soft gels in your hopper, then such products are just a waste of time and resources.

Filling head

This part is at the center section of every softgel encapsulation machine (sealing side). The filling head is mounted on a softgel encapsulation machine.

It is responsible for dispensing soft gelatin capsules into the soft material in a controlled and uniform manner. This is done by mounting the softgel capsule on top of the plunger gently, then pushing it deep down into soft material until it is full with soft material and gets lifted by the spring mechanism attached to its base.

The purpose of this mechanical process should be to pack soft lax powder or other soft materials inside soft gels so that every gel has an equal quantity of the ingredients present within them (evenly).

The filling head must have an air-tight design made from high-quality plastic components so that no powder particles escape during the sealing process thus maintaining quality standards at all times. It is recommended to buy a softgel capsule sealing machine that has in-built functions to prevent leakage of soft material from softgel and subsequent formation of a solid mass inside soft gels. it).

The filling head must have depth controls for adjusting output levels. This way you can adjust its setting to precisely control output volumes which subsequently leads to more economic usage of raw materials in the long run.

Wedge

This softgel sealing machine component is placed on the soft gel soft-sealing side of the softgel encapsulation machine. It helps to consolidate soft material content within soft gels and prevent it from spilling outside during post-processing steps. This prevents leakage and formation of hard lumps inside soft gels that are not edible nor can they be used properly in any way by consumers who buy them.

The wedge must have an air-tight design made from high-quality components so that no powder particles escape during the sealing process thus maintaining quality standards at all times. It is recommended to select a model with perfect shapes, sizes, and designs for wedges as this will directly influence the final product’s overall appearance, aesthetic qualities (appearance, feel, and colors) & softness.

Spreader box

This soft gel soft-sealing machine component spreads molten gelatin once it leaves the mixing tank.

It helps in regulating the amount of soft material to be fed into the soft gels during the filling process thus ensuring that predetermined volumes are achieved with every batch.

It can also help in controlling pressure levels & quantities when soft material content inside softgels is being filled if it has a special design and features for this purpose.

Soft Gel Sealing Unit/Mould:

This part is placed at the bottom section of (near or within) the whole soft gel encapsulation machine. It performs all sealing activities like closing, lidding, fixing, etc.

The most important function that is performed by this softgel encapsulation machine unit is to heat soft gelatin capsules at the right temperature so that soft material inside soft gels heats up uniformly and becomes soft enough to be filled.

Die roll:

It performs soft gelatin soft-sealing activities through turning or rolling movements at a certain speed, intensity, and pressure level (if any). Die roll must be made from high-quality plastic components so that no powder particles escape during the softgel encapsulation process thus maintaining quality standards at all times.

Mixing tank:

This is the place where soft lax compound gets mixed to create a homogenous mass of soft material on which subsequent processing steps are performed. Soft material present in the mixing tank can also be mixed automatically through an automation system if available in a softgel encapsulation machine.

Pneumatic system

This soft gels encapsulation machine component comes with enough blow sources to blow/apply pressure onto softgel seals to completely fill up soft gels with soft material content present within them.

Pressure levels & quantities are controlled individually using flow meters along the whole pneumatic softgel encapsulation machine processing line. Pressure levels can also be controlled automatically using softgels encapsulation soft-sealing machines.

Capping unit

This part is placed at the top section of (near or within) the whole softening soft-encapsulation machine. It performs sealing activities like closing, lidding, fixing, etc. on already filled soft gels to create perfect softgels with complete material contents inside them.

Packing unit

This softgel soft-sealing machine component helps in closing, lidding, and packing softgels into desired quantities thus completing the entire encapsulation process.

It can have advanced features like an air-tight design for perfect sealing, automatic package quantity filling/packaging of softgels into zip bags, among other packaging options

Advanced features are decided by end-users depending on application requirements at hand while buying a softgel encapsulation machine for their specific needs and applications.

Chapter 5: Technical Specifications of Softgel Encapsulation Machine

When buying a softgel encapsulation machine, it is important to pay attention to its technical specifications. This is because they determine the overall performance of the machine.

Some of the important technical specifications that you should know include:

Speed of the machine:

This defines the number of softgel capsules that the machine can encapsulate within a given period. Normally, softgel encapsulation machines range from 60 softgel capsules per minute to 300 softgel capsules per minute. The speed is usually set by the manufacturer and it can be adjusted depending on need.

Style of softgels:

This refers to the design of softgels that have been made by the softgel encapsulation machine. There are mainly two types of softgels available which include flat softgels and round softgels.

However, there are also three-sided oval softgels designed for use in Japan, where they are well received by customers due to their efficacy as well as taste quality.

You may want to look out for these styles when buying your softgel encapsulation machine since they offer a soft and easy-to-swallow supplement.

The type of softgels that can be supported

You must understand the difference between soft gel capsule shell material and softgel softgels fillings. Soft gel shell materials include hypromellose, gelatin, hydroxypropyl methylcellulose phthalate, polyethylene glycol, and a combination of two or more of these substances.

The softgel fillings on the other hand can be made from oils such as black currant oil, borage oil, and linseed oil among others. These are just but a few examples since there are soft gels with unique fillings available as well so make sure you choose what works best for your customers.

Number of tumble dryers

Softgel encapsulation machine for sale is made in different types and you can choose those that have either one or five tumble dryers. The number of tumble dryers will depend on the need.

However, it is important to note that soft gel capsule encapsulation machines for sale that have more tumble dryers are generally costlier

Capacity

Softgel encapsulation machine comes in different capacities. In order to know what softgel capacity suits you, simply identify the number of soft gels capsules you wish to produce each day and then multiply this by 365 days per year.

This will give you an approximate idea of the softgel machine upper limit that you will need. However, some softgel encapsulation machines are available in capacities of up to 30,000 soft gels capsules per day.

Maximum softgels size the machine can accommodate

Softgel encapsulation machine comes in different sizes and shapes. This is why it is important that you buy a softgel encapsulation machine based on the maximum softgels size it can accommodate. Failure to do this might result in some softgels being left out while others are forced inside the machine. This will affect both their quality and quantity.

Power consumption

Softgel encapsulation machines are relatively power-consuming machines. This is why you should ensure that the softgel encapsulation machine you buy is made of energy-efficient materials. Verify the power consumption rate of the softgel encapsulation machine before buying.

The size and dimensions of the machine

Softgel capsule filling machine is available in different sizes and this includes small, medium as well as large.

The size of the machine that you choose should be a reflection of your production capacity. It will also depend on the number of softgels capsules you want to produce on daily basis.

Control mechanism

The softgel encapsulation machine for sale must have a control mechanism that is easy to use. This will help in reducing errors during production time and avoid having to employ extra labor. Find out the type of HMI that is on the control panel

Pressure

There are different types of pressure used in making the process of encapsulating process easier as well as faster. Depending on your preference, you can choose hydraulic press, pneumatic/air, and even manual pressure.

Chapter 6: Softgel Encapsulation Machine Design and Structure

Softgel encapsulation machine is characterized by an agile structure and ergonomic design. The softgels are soft and soft, which has a soft mouthfeel. At the same time, it is easy to swallow and digestible in the human body.

There are many softgel encapsulation machines on the market, but most of them have a similar structure. Therefore, this article will mainly introduce softgel encapsulation machine design characteristics of different brands.

Appearance

Generally, softgel encapsulation machine models have a full black appearance, with glossy knob caps. Appearance is simple and easy to operate. When people want to use this softgels production line. They do not need any complex operation, only need to follow some operations in accordance with their specific instructions.

The equipment uses advanced control system technology, precise temperature control, high-speed suction, and other technology to ensure softgel production efficiency.

Structure

The softgels encapsulation machine is equipped with a softgels production line, loading device, product washing device, drying device, and other auxiliary equipment.

Softgel capsule filling machine has adopted the drive system of servo motor, the soft gels are automatically transported to different positions. The whole softgel encapsulation process is fully automatic.

No matter which soft gel type, all the processes can be operated by one or two people on one operation console without any difficulty.

Design

This softgels encapsulation machine also comes with a unique design that ensures each softgels surface smoothness(no bubbles), to reduce side effects caused by reshaping capsules into irregular shapes because of the sputtering machine.

Softgel encapsulation machine softgels production line adopts the advanced pneumatic soft packing system to pack softgels, which not only ensures softness but also saves labor costs.

Frequently Asked Questions About Softgel Encapsulation Machine

Chapter 7: Frequently asked questions about Senieer Softgel Encapsulation Machine

Here are some of the most questions that people ask about soft gelatin encapsulation machine and their answers:

What are soft gel capsules?

These are capsules that are enclosed in soft gelatin and used for oral administration. The gelatin is made of a special material that protects the content inside.

How softgel encapsulation machine work?

Softgel capsule machine consists of soft gelatin capsules and soft gelatin capsule filling equipment (also known as soft gel filler) which softgels produce the finished products.

The soft gelatin capsules are made from hydrophilic polymer membranes that are contained in the oil, water, or other fluid substances which the small volume consumption liquid can pass through. In a softgel encapsulation machine, soft gelatin capsules will absorb the fluids by sealing the required amount of fluid that users want into soft gel capsules.

What kinds of industries will benefit from Senieer Softgel Encapsulation Machine?

Senieer soft gelatin capsule filling production line would be good for any factory or pharmaceutical company who wants to produce softgels by themselves. This is because there are many soft gelatin encapsulation machines available in the market.

Some of the industries that use the soft gelatin capsule filling machines include pharmaceutical, food companies, chemical companies, laboratories, biotechnology among others.

How does the encapsulation machine verify the quality of the softgel capsules?

The softgel encapsulation machine verifies softgel capsule quality in three ways:

The first way – the softgel capsules are tested internally after softgel capsules come out of the softgel encapsulation machine and before reaching the storage area.

This is because the softgel capsule production process can leave remnants of oil on the shell surface which can cause a bad taste or other problems like an allergy when they go into the human body. So just to make sure there is no problem inside, soft gel capsules are checked with a special device for any imperfections in the shell such as holes or cracks after leaving the softgel encapsulation machine.

This step ensures that you get perfectly soft gel capsules as per your order for your customers.

The second way – softgels leaving softgel encapsulation machine are not soft gels by the time they get to the storage area. There is one extra step of filling softgels into soft gel capsules after softgel capsules come out of the softgel encapsulation machine. It can be done manually or with some automatic equipment.

The third way – after softgel capsules are filled into soft gels, they are tested again before packaging and shipping. It’s the final test to make sure that softgels have no bad taste or smell. This soft gels machine step ensures the quality that you get is consistent and guaranteed.

Which support equipment do you need for the encapsulation machine?

You will need a softgels filling machine as supporting equipment to the softgel encapsulation machine for the softgel capsules filling process.

Are there any standard softgels offered by the soft gel capsulation machine manufacturer?

Yes, soft gel capsule machinery manufacturers are required to adhere to different international standards for the machine. One of them is the cGMP standard.

Softgels shell maker seller will help you decide which standard softgel encapsulation machine meets the requirement for your soft gel capsules soft gels filling process.

How much does the softgel encapsulation machine cost?

Just like any other machinery or equipment, softgels machines differ in price depending on a number of factors. These include such as quality, brand, capacity, softgels capsules soft gels filling process, and others.

If softgel encapsulation machine supplier can give you detailed soft gel capsule soft gels making process prices based on your softgels specifications.

How long does the softgel encapsulation machine last?

The life span of a softgel encapsulation machine is between 5-8 years depending on the operating environment and softgels production volume per day

How softgels are loaded into soft gel capsules?

The softgel encapsulation machine is programmed to make the softgel filling process simpler and more efficient.

Soft gels or softgel material (like soft gel oil) come in a tank that is connected with the softgel encapsulation machine. When you need soft gels, just press soft gel fill softgel capsule filler to make the encapsulation machine start the softgel filling process.

Is it easy to clean?

That’s right. Softgel encapsulation machine is compatible with soft gel encapsulation machine cleaner. So, soft gel capsules can be cleaned easily and quickly by a softgels capsule cleaning soft machine. The cleaning process is fully automated.

What is the capacity of the softgel capsule machine?

The maximum production output can reach up to 2000-3000 soft gel per hour. However, the machine’s production can be customized to meet your productivity needs.

Does the softgel encapsulation machine come with a warranty?

Yes. Soft softgels softgel capsule making process machine is protected under a 1-year warranty. Softgel encapsulation machine manufacturers can offer you an extended warranty if the soft gel encapsulation machine supplier adds an extra charge.

How often do you need to clean your soft gel capsules?

The cleaning frequency of softgel soft capsules soft softgels soft gel filling machine depends on how softgels softgel capsule soft fill machine is used.

If there are many sticky substances left inside, the soft gels capsule machine must be cleaned every 1-2 hours.

However, if you use a vacuum to clean up loose materials during operation, the softgel capsule filling machine will not need soft gel capsules soft gels cleaning every 1-2 hours.

Chapter 8: Senieer Softgel Encapsulation Machine Line

Senieer is a reliable pharmaceutical machine manufacturer in China. One of our product lines is the softgel encapsulation machine.

We have been developing a softgel encapsulation machine for years, and we are very familiar with the softgel encapsulation machine design process. The softgel encapsulation machine is a patented product of Senieer.

We offer softgel encapsulation machine installation, softgel encapsulation machine maintenance, and softgel encapsulation machinery replacement or extra parts service to our clients all over the world.

We provide softgel encapsulation machines suitable for customers’ large-scale production requirements. Our softgel encapsulating machines can be used in producing softgels containing different materials such as oil, API, and powder drugs.

Senieer softgel encapsulation machines are the ideal soft gel capsule filling machine if you want to package softgel capsules.

More details could be seen in the soft gelatin capsule manufacturer section.

We also provide a soft gelatin capsule filling machine to fill soft gelatin capsules and hard capsules like glass hard capsules and plastic hard capsules.

We also customize softgel soft encapsulation machines and soft capsule filling machines especially for you.

Senieer softgel soft capsule encapsulating machine can be used in producing a large number of softgel capsules in bulk or individual packaging.

Senieer soft capsule filling machinery provides high-quality products to our customers at very competitive prices within an extremely short period. Our standard sample production time for 1 set soft gels soft capsule filling machine is approximately 21 days while the customized samples take around 35~40 days.

Conclusion

In conclusion, it is clear that a softgel encapsulation machine is an ultimate solution for any business or organization that deals with the production of soft gel capsules.

Once you get the right machine, you will be amazed by the level of productivity that you will experience. Of course, the whole secret lies in choosing the best softgel encapsulation machine manufacturer in China.