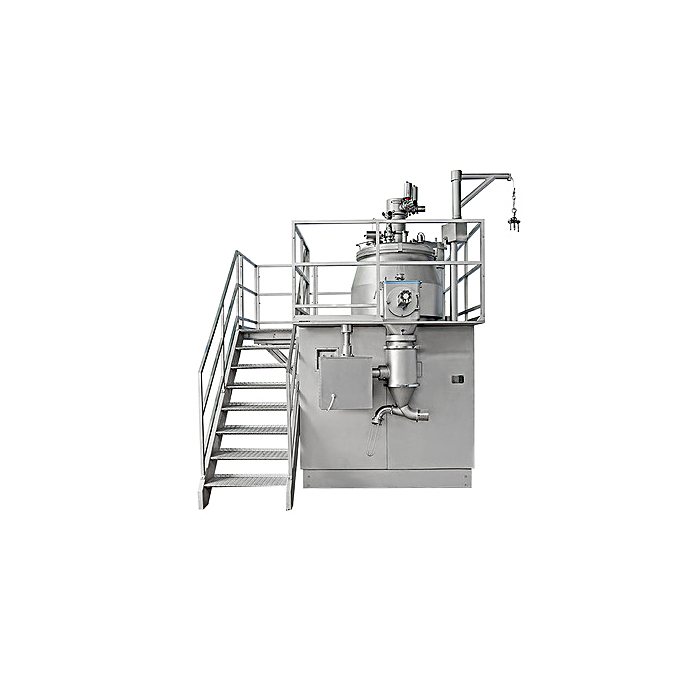

GM400 High Shear Mixer Granulator

- Automatic PLC control, mixing, granulating and milling

- Equipped with impeller and chopper which ensure excellent granulation

- Big specific density difference

- Products are firm and uniform and high yield

- Automatic judging of the terminal point of granulating process

- Having good process reproducibility

- Impeller and chopper blade axis adopting pneumatic

- No dead angel, no cross contamination

- High shear mixer granulator meets the requirement of cGMP

Your Premier GM400 High Shear Mixer Granulator Manufacturer

Senieer GM 400 High shear mixer granulator also named GM 400 High shear mixer. GM 400 means 400L of the bowl, the capacity from 80kg to 160kg depend on different densities.

Senieer GM 400 High shear mixer granulator is widely used in such industries as drug, food, health products, chemical industry, dairy products, etc. Senieer custom designed and manufactured completely comply FDA and cGMP standards.

The processing bowl is designed in a conical form and has a rounded corner bottom design to ensure good product movement and to eliminate dead spots. The processing bowl is manufactured in 2 bar resistant design. Lid in lift-open with labor saving design for easy operation.

The sealing between the lid and the working bowl is carried out by means of silicon rubber gasket, which is made of food grade silicon rubber and easily to remove for cleaning and maintenance.

The working vessel and the lid are single wall, double layer wall for option if necessary.

Following ports are installed on the lid:One port for manual feeding hopper or other accessories, including blind plugs

One port for a outlet filter, The textile filters are made of antistatic polyester. There is a tempered safety sight glass on lid for observing products.

Senieer has the ideal solution for the GM 400 high shear mixer granulator and your different demands in determining torque. In addition to the power consumption of the frequency converter used as standard, the direct power consumption of the impeller motor can also be measured. Both variants are affected by energy transfer disturbance variables and the possible wear of mechanical parts.

As a leading GM 400 high shear mixer granulator manufacturer and supplier. Senieer has focus on rapid mixer granulator technology development more than 30 years. Senieer is your reliable high shear mixer granulator wet granulation choice for you, never hesitate to contact with us now.

- Send Inquiry