Fluidized Bed Dryer

- High yield reaches up to 99%

- Fluid bed drying complies with FDA/cGMP specifications for processing.

- The drying machine ensures a fast and uniform drying process.

- Fluidized bed driers are simple to use and require less effort.

- Fluid bed drying has low maintenance cost

Fluidized Bed Dryer : Product Description

fluidized bed dryers are machines that are primarily used in the pharmaceutical industry to decrease the moisture content of medicinal powders and granules. Fluidization of the input materials is the basis of the fluid bed dryer design.

Hot air is delivered at high pressure through a perforated bed of wet solid particles in a fluidized bed drier. The liquid solids are sieved from the bottom and suspended in an air stream (known as a fluidized state). Direct contact between the wet substance and the hot gases is used to transfer heat. To evaporate liquid that is transported away by the drying gasses, an airstream chiller is employed. In a fluidized bed dryer operation, the leftover gases are recycled back into the system to save energy.

Details of Fluidized Bed Dryer

▣ G4 Filter, F8 Filter, and HEPA filter

▣ Wheel dehumidification system is available

▣ Stainless steel AISI 304 or carbon steel material dust collector

▣ All the parameters can be memorable, can be printed

▣ Process times significantly reduced, rapid drying and uniform

▣ Siemens intelligent touch screen control system

▣ No dead zones in the product container

▣ Processing of materials with different densities

▣ fluidized bed dryer can work with high shear mixer

▣ Steam heating or electric heating two kinds of heating modes

▣ The sampling feature is included in the fluidized bed dryer.

▣ The proportional modification of the inlet air pressure valve is used.

▣ One fluidized bed drier can be equipped with one more product container

▣ WIP systems for automated washing could be added to fluid bed dryers.

▣ Fluidized bed driers can be provided with 2 bar, 10 bar or 12 bar explosion-proof design

▣ Heat-sensitive items should be dried in a fluidized bed.

▣ The fluid bed dryer guarantees good material drying quality and yield.

▣ Air handling unit (AHU)part, first filter, secondary filter and HEPA filter, high degree of automation

▣ FBD has two filter chamber, hot air takes away moisture quickly

▣ FBD drying process technique and efficiency is better

▣ Fluidized bed drier has high expansion ratio and enough fluidization space

▣ Use high-pressure fan, through negative pressure form, quickly bring heat to come over

▣ Three grade filters purified fresh air of AHU

▣ Air volume measurement unit with high precision

▣ Air pressure measurement unit with high precision

▣ Granules and powder dry easily, and there are no broken bits.

▣ No cross contamination, total containment

▣ The drying chamber has a high structural strength and is simple to clean.

▣ FBD lab fluid bed dryer is simple to use and dismantle, and it takes up little space.

▣ A small batch experiment can be done with a mini fluid bed dryer.

▣ Intelligent touch screen operating system, automatic PLC control

▣ All the parameters can be memorable, transfer to SD card and USB

▣ Printer is available, printing process parameters

▣ Multilevel of operation authority can be set

▣ Strongly aligned with cGMP guidelines.

▣ Fluidized bed dryers operate on the fluidization principle, which is the conversion of a substance from a rigid solid-like state to a dynamic fluid-like state. Hot gas or air is introduced into the material-holding region via a perforated distribution plate in this process. This hot gas pushes its way through the gaps between solid particles. The upward forces on the particles increase as the velocity of the gas or air increases, forcing them to equalize the gravitational forces below.

▣ This results in a state of fluidization, in which the molecules are suspended in a boiling liquid bed. What was once a rigid object will now flow like water. Each particle is in close contact with another particle. Each particle is in close contact with the hot gas or air and is surrounded by it, resulting in an effective and uniform drying operation.

▣ Chemical

▣ Pharmaceutical

▣ Food

▣ Health

▣ Dairy

▣ Metallurgical

▣ Dyes

▣ The machine can handle a large volume of fluids.

▣ Fast and homogeneous drying is ensured by fluidized bed dryers.

▣ The fluidized bed dryer is ideal for non-sticky and heat-sensitive materials.

▣ At low temperatures, fluid bed dryers are effective at drying materials.

▣ FBD is simple to handle and requires minimum effort.

▣ Machines come in a wide range of capacities and sizes.

▣ Fluidized bed dryer has a standard specification and can also be customized to meet the needs of the customer.

▣ Since the fluidized bed dryer is low-maintenance, it reduces downtime.

▣ There are no hot spots on the finished goods.

▣ The machine can handle both continuous and batch material sorting.

Any Question About Senieer fluidized bed dryer

Why Global Company Trust Senieer

Top Quality Factory Price

We have a quality control department to verify each fluid bed dryer at different phases, from the procurement of parts to finished products

As Your Layout, Customize Machine

According to your layout, we can suggest the best capacity and type for you, customize fluidized bed dryer for you

Fluidized Bed Dryer Consult & Design Service

Save energy resource for you, professional engineers can improve the best processing solution. We have the experience to help add a tremendous amount of value to your project

ISO.CE Standard Qualified

We successfully obtaining the ISO9001:2008 certificate and CE security management system certificate, this is significant for Senieer in building enterprise image

Fluidized Bed Dryer Training & Maintance Service

Free fluid bed dryer training & maintenance service for you, we will provide your team in-depth training on safe operation and fluidized bed dryer maintenance

Fluidized Bed Dryer Installation Service

Senieer offers fluidized bed dryer installation & commissioning service for fluidized bed dryer, your fluidized bed dryer and control systems are qualified based on the GAMP life-cycle

Fluidized Bed Dryer: Ultimate Guide For Importers

Let’s dive right in:

- Chapter 1: What is a Fluidized Bed Dryer?

- Chapter 2: Fluidized Bed Dryer Design and Construction

- Chapter 3: Fluid Bed Dryer Working Principle: How it Works

- Chapter 4: Fluid Bed Dryer Parameters and How They Affect the Product

- Chapter 5: Types of Fluidized Bed Dryer

- Chapter 6: Factors to Consider When Buying a Fluidized Bed Dryer in China

- Chapter 7: Applications of Fluidized Bed Dryer

- Chapter 8: How to Choose Fluidized Bed Dryer Manufacturer

- Chapter 9: Frequently Asked Questions about Fluidized Bed Dryer

Let’s say you are in the pharmaceutical field and specialize in making pharma products. This can be solid dosage forms such as tablet pills and capsules. At the end of the process, you would like to deliver the products when they are completely dry.

The purpose of drying is to ensure that you get rid of all the moisture that is embedded in the material for the product. This is vital because some production processes may entail the addition of water or other fluids. Wet granulation is one of these processes.

So, how can you achieve maximum drying? This is where a fluidized bed dryer (fbd machine) comes in. It is used for drying purposes.

Are you planning to buy a fluid bed dryer in China or you are looking for the best equipment to dry your ingredients? This is a perfect guide for you. We are going to look at everything that you should know about a fluidized bed dryer.

At the end of the guide, you will be in a position to make an informed decision regarding the purchase of this equipment. You will also be able to select the best fluid bed dryer manufacturers and suppliers in China.

Chapter 1: What is a Fluidized Bed Dryer?

A fluidized bed dryer, which is also known as a fluid bed dryer is pharmaceutical equipment that is used for reducing moisture content in materials. The materials can be powders, grains, and granules that are used for making different products in the pharmaceutical field.

A fluid bed dryer utilizes the principle of fluidization to minimize the moisture content in the material. Here, a stream of hot air passes through the material carrying along with it the moisture that might have been embedded in the material.

The good thing about the fluidization process is all the particles that make up the material are exposed to the following air. This increases the drying rate of the material.

A fluid bed dryer has many other components which work together to achieve the maximum drying of all the materials. The design and construction of the pharma dryer also maximize the drying of the materials without having any negative effects on the materials that are being dried.

1.1, What is the importance of drying the materials?

Drying is an important practice in the food pharmaceutical and chemical industries. It is one of the lasts processes that are done on the products before they are packaged or even before they are subjected to further processing.

To understand the importance of a fluid bed dryer, it will be necessary to look at why products and materials need to be dried. Here are some reasons and benefits of drying;

1.1.1. Provides a safe form of storing the products

After the pharmaceutical or food products have been processed, they won’t be used immediately. Instead, they will be stored to be used later on. The storage will be more effective if the products and materials are dried and devoid of moisture.

Dried food materials can be stored for an extended period without you having to worry about the safety of the products. Also, dried materials tend to be compact and occupy a smaller surface area than wet food materials.

1.1.2. Eliminate molds and other toxic matter

The wetness of materials is a perfect breeding ground for toxic matter such as molds and other growths. Also, some materials tend to undergo a constant chemical reaction when wet.

This is a serious threat to the quality of the products and materials being processed. It can make the products to be toxic hence unsuitable for human consumption.

Drying prevents the build-up and growth of toxic matter in the materials and products. This will eventually lead to enhancing the safety of the products.

1.1.3. Minimizes wastage of the materials

The drying process ensures that there is a 100% transition of materials from one stage of production to another. As we have seen, the dried materials are easy to store and also safe from damage due to chemical action.

There will be minimum loss of material recorded during the transition process. As the rule of thumb dictates, less wastage means a higher profit margin.

1.1.4. Easy to transport

If the dried materials are easy to store, they will be easier to transport. You will have an easy time transporting the dried products since they are easy to handle. On the other hand, transporting wet materials and products can be quite a hectic process.

1.2, Why do you need a fluid bed dryer for drying?

Now that we have seen the importance of drying the ingredients, the next question that you are likely to ask is whether you need a fluidized bed dryer to do the job. After all, there could be other equipment and even methods for drying the materials.

A fluidized bed dryer is special equipment for the job because of the following reasons;

1.2.1. Uniform drying

You can easily achieve a uniform dying of the materials with the help of a fluidized bed dryer. His is where all the particles of the material lose an equal amount of moisture. No section of the particles appears to be drier than the others.

The fluidization process ensures that there is equal distribution of hot air throughout the drying chamber. This means that all of them will dry up at the same rate. The design also ensures that all the particles are properly aligned in the fluid bed dryer.

Uniform drying helps to improve the quality of the materials. It ensures all the aspects of the products are to perfection. You will discover this if you compare products that have been dried up in the fluid bed dryer to those of other methods.

The uniformity of the drying process also ensures that the final products are devoid of hot spots. This is possible because the material to be dried is suspended freely in the drying chamber from where it is exposed to heat evenly.

1.2.2. Fast drying

You can save a significant amount of your production time when you incorporate the use of a fluid bed dryer for drying up the materials. The speed of a fluid bed dryer is unmatched whether it is batched processing or continuous processing of pharmaceutical products.

Once the material has been fed into the drying chamber, it will be dried up instantly by a stream of pressurized hot air. Also, the whole batch of the material is dried within a short time and this will allow you to take the next batch almost immediately.

You can also increase the rate of drying the materials by getting a high-capacity fluid bed dryer. Such types of dyers are designed to handle high volumes of materials at any given period.

1.2.3. Multifunctional machine

A pharma fluid bed dryer is a versatile machine that is capable of fulfilling different production needs in a pharmaceutical setup.

You can use a fluidized bed dryer for both batch processing and continuous processing. Your type of production should not hinder you from incorporating this pharmaceutical equipment.

Still, on the versatility, you can use an fbd for drying up different types of materials. Whether you can use it for grains, granules, powder among other materials.

Also, fluidized bed dryers allow you to exercise an array of control measures. You can control the level of drying that this pharma machine should achieve in a particular type of material.

1.2.4. High levels of hygiene and sanitation

It is easy to observe high hygiene levels when using a fluid dryer. Manufacturers use different methods to ensure that the machine does not compromise its cleanliness levels.

First, the choice of materials for making the fluidized bed dryer minimizes reactions that can lead to contamination with the ingredients. Stainless steel is inert to chemical reaction hence it won’t react with the materials that are in the drying chamber.

The design of the fluid bed dryer prevents foreign objects from getting into the drying chamber. The fluid bed dryer is properly enclosed with functional lids that block objects in and out of the equipment.

Also, the fact that it is easy to clean an fbd pharma dryer ensures that you will be able to achieve the highest sanitation standards at all times. You will always clean the pharma equipment whenever you want to dry different materials. This way, you will prevent cross-contamination due to the use of different materials on one pharmaceutical fluid bed dryer.

1.2.5. Easy to use

The simple design and construction of the fluidized bed dryer are of great benefit to the users. You will have an easy time when handling and using this pharma machine. Every component of the machine is within your reach and this is mainly because of its compactness.

An advanced fbd control panel allows you to execute various operational and control parameters without any problem. The agile design also allows users to move the vertical fluidized bed dryer to whichever location that they want You will also have a smooth time when installing the fbd and connecting it to other pharma machines.

1.2.6. Ideal for heat-sensitive materials

Most methods for drying materials entail the use of heat. In some heat is directly conveyed to the product so that it can get rid of water or moisture. However, some materials and products are sensitive to high temperatures. Their quality may diminish and others are even destroyed by the impact of high heat.

Fluid bed dryers may be suitable for these materials as it minimizes direct impact between the heat source and the products in question.

Also, fbd pharmaceutical machines have sensors that play a role in regulating the temperature inside the heating chamber.

1.2.7. Low maintenance cost

Fluidized bed dryers are cheap and easy to maintain. One of the reasons for this is the simplicity of the pharma machine. The fluid bed dryers do not consume too much electricity energy. This means that you will not be bogged by the issue of high electricity bills.

Also, the fact that the fbd pharma machine is refined to precision means that you will not spend too much on dealing with the breakdowns.

Chapter 2: Fluidized Bed Dryer Design and Construction

Now it is time to have a deep outlook at the fluidized bed dryer. To understand how it works and its operational principle, it will be prudent to look at each part and component of this fbd machine. We will also look at how they are designed to work with each other.

2.1. Main parts of a Fluid Bed Dryer

The main parts and components of a fluid bed dryer include;

2.1.1. Air preparation and compression unit

This component is the starting point of the fluid bed dryer. As we have said, the working mechanism of the fluidized bed dryer depends on a stream of hot air that blows over the material. This air comes from an air compressor and preparation unit.

The air preparation unit prepares the air that should get into the main container to dry up the materials. It ensures that this air is of high quality and meets all the minimum requirements for the drying of the materials.

The preparation unit filters out moisture and solid particles that might have been trapped in the air. This ensures that only pure enters the drying container. Contaminated air may mix with the materials and affect the quality of the products.

The air preparation unit is also responsible for the regulation of air pressure. It receives signals from the control unit and b determines the intensity at which air is blown into the container. In short, this unit ensures that the best quality air is used for the fluidization and drying of the materials.

2.1.2. Exhaust filter

The air from the air preparation unit will then be transmitted to the exhaust system. Here, it will have to be filtered to trap all the impurities that might have passed through. This component of the fluid bed dryer also helps to preserve the quality of air that is used for drying the materials.

The exhaust filter in most fbd in pharma is positioned right next to the product container where the drying will take place. The stream of air that goes through the exhaust filter is now ready to be used for drying up the materials.

2.1.3. The spraying nozzle

The spray nozzle helps to direct the fluidized materials into the fluid bed dryer so for drying. The design of the nozzle ensures that it directs the materials in a special way that is different from the ordinary pipes.

The design of the spray nozzle ensures that it breaks up or splits the fluid in different directions. This ensures that all the particles are exposed to heat during the drying process.

Spray nozzles come in different designs and configurations. You can choose a double swirl spray nozzle, flat fan spray nozzle, disc spray nozzle, or any other spray nozzle that will fit into your system.

The good news is spray nozzles are adjustable and replaceable. You can change the nozzle depending on the type of material that is to be dried in the fluid dryer. The best cheat sheet here is to deeply analyze the properties of your fluid material and choose the spray nozzle that will match its requirements.

2.1.4. Air distribution plate

This component of a fluid bed dryer is responsible for distributed a stream of compressed air in the drying container. It is designed to transform wet materials that have been conveyed into the chamber into dry granules and dry powder.

A typical air distribution plate has numerous holes which ensure that there is optimal delivery of air. Also, the holes are aligned at specific angles to ensure that all the sections of the fluid bed dryer get the air.

Like other fluid bed dryer components, air distribution plates come in different designs, styles, and configurations. Each configuration is designed for a specific fbd dryer for optimal performance.

2.1.5. Fluid bed dryer container

This is the main component that supports the drying process of the material. It is the main support system in that all the materials have to be conveyed to the main container so that the drying process can commence.

As the main container, it is made of high-grade material such as stainless steel. This material can withstand the vigorous process of fluidization. This means that it can withstand corrosion hence is durable.

Also, steel is inert hence will not react with the materials even under high temperatures.

Product containers for the fluidized bed dryers come in different shapes, designs, and even dimensions. The size of the container will determine the capacity of this pharma drying machine. The larger the container, the more the handling capacity of the fluid bed dryer.

Also, the shapes and designs of the fluid bed dryers affect their performance and handling capabilities. T

The good thing is you can choose different designs, shapes, and capacities of the Senieer fluid bed dryers. The choice will mainly be based on your desired levels of performance.

2.1.6. Fluid bed dryer control pad

Different types of materials required different levels of drying and fluidization. It is up to you to control the operation of the fbd dryer so that it can dry the material based on specific conditions. You can do this using a control panel that is embedded on the fbd machine pharma.

The control panel is engineered to sense all the activities and processes in the fbd machine. It also determines how each process should be executed in the fluid bed dryer. In other words, it is a computerized or programmable logic control component of the dryer.

Would you like to increase the drying rate of the fluid bed dryer? Simply enter your inputs into the fbd panel and it will execute your instructions.

An important feature of the Senieer control cabinet panel is the user-friendly interface. You can use it easily without straining. It is also waterproof meaning that its performance or even functionality will not be hindered by the presence of water.

2.1.6. Liquid delivery system

This is a high-purity component that is used for delivering the fluid material into the fluid bed dryer’s atomizer.

The system is designed and manufactured to facilitate a smooth flow of the liquid. It should not interfere with the flow or even the quality of the material.

The solution delivery system comprises of different components which include a magnetic filter, a pump, and in some cases a liquid tank. All these components work together for the efficient delivery of the material. These components tend to vary in different machines depending on the specifications.

2.1.7. Fluid bed heating system

The drying process entails the use of heat energy to the materials. In this case, hot gas is used for heating the materials and eradicating any elements of moisture from them.

The heating system of a fluid bed dryer is accurately designed to deliver the right temperature that is needed for eradicating moisture. It should be able to achieve this goal without damaging the particles of the materials.

The heating system of the fbd pharma dryer comprises of an electric steam radiator a which delivers the required heat to the gas.

The heating system is strategically positioned in the stainless tubes that are used for heating gas. This positioning allows them to heat every ounce of gas that passes through the tube.

Also, the process of heat generation is fast so that it can keep up with the velocity of the fast-moving compressed air.

Heating can be regulated to protect the materials from exposure to high heat. The regulation also ensures that each particle is heated to the optimal level.

2.1.8. Dust collector

This is another important component of a fluid bed dryer. As the name suggests, its work is to trap dust that has been generated during the fluidization and drying process.

The dust collector helps to keep the indoor air clean and improve the working conditions of your workspace.

Even though it may work as a unit, a dust collector comprises various parts such as cone pipe and dust packet. Some are fitted with special screens to filter out toxic materials from the dust. Also, the specifications of a dust collector may vary from one fluid bed dryer to another.

2.2. Fluid Bed Dryer Diagram

As we have seen -n the previous section, a fluid bed dryer is one machine that is made up of different components. Each part has a special role to play in drying the materials.

We will enhance your visual understanding using this diagram of Senieer fluid bed dryer;

As you can see from the above diagram, each component is strategically positioned to perform the required task efficiently. The design of the product container allows the free flow of the materials to be dried.

The fluid bed dryer is supported to the ground by sturdy frames which ensure that it remains stable during the fluidization process.

2.3. Key Features of Senieer Fluidized Bed Dryer

Despite having the above parts, not all the fluid bed dryers in the market are the same. They have different features and characteristics.

Here are some key features that make Senieer fluid bed dryer stand out from the rest in this competitive market;

- Modular design:The modular design of the fbd pharma machine simply means that different components are integrated to form a single unit. The end-product is simple and easy to use.

- Constant rate of drying; our high-performance fluid dryers can operate continuously without fluctuating temperatures. The constant rate is critical in promoting uniformity of the materials.

- Fireproof construction: The materials used for constructing the Senieer fluid dryer are of high quality and resistant to fire and flames. You can have peace of mind knowing that your machine won’t be damaged in case of fire incidence.

- Time and temperature controls: You can use the fluid dryer controller to regulate the temperature of the operation. This feature will allow you to dry different materials safely. The timer control feature also allows you to regulate the period under which the material should be dried.

- Easy to install and uninstall: You can easily install and uninstall different parts of the fluid bed dryer. For example, you can install a different heat exchanger in case you want to dry different classes of materials.

- Suitable for different materials:You can comfortably use Senieer fluid bed dryer for drying different types of solid dosage forms. It can be used on powder, grain granules, among others.

- High thermal efficiency: The fluid bed dryer is designed to maximize the heat that it generates. There is minimal wastage of heat as most will be absorbed by the materials.

- High drying efficiency: This feature simply means that the machine removes all the moisture in the materials to achieve the desired dryness.

Are you impressed by the above features of the Senieer fluid bed dryer? It is time to take that noble step of contacting us and placing your order.

Chapter 3: Fluid Bed Dryer Working Principle: How it Works

A fluidized bed dryer is designed to reduce the moisture content in solid dosage forms. But how does it manage to achieve this goal?

As we have seen the fbd pharma dryer has different components that are coordinated to work together to ensure that you achieve the ultimate dryness on the machine.

A stream of air is directed to the chamber containing the dry material. This airstream flows upwards from the chamber below and has a higher velocity than those of the particles that are settling in the chamber. The difference in velocity means that the particles of the materials will remain suspended in the air.

The flow of air in the product container marks the start of the fluidization process. It also increases the speed at which the material dries up. Since the Senieer fluid dryer container is made of stainless steel, it will support all the activities taking place in the fluidization chamber.

A removable bowl-like container is positioned at the bottom of the chamber. This container is used for the storage of the materials

A controller that is embedded in the fluid bed dryer is used for controlling the velocity at which air flows into the drying chamber. You can increase or decrease the speed of the airflow depending on the level of dryness that you intend to achieve.

The static contact between the air and the material is a key factor that makes the materials dry. The air will then exit the chamber through the air filter. The drying can also be due to an increase in the particle surface area due to the velocity of the air. The fluid bed dryer bags which are installed in the drying chamber also speed up the rate of drying.

The buildup of static charge is a big issue that is likely to arise in the fluid bed dryer. This is caused by the interaction between the suspended particles and the flowing air. However, the best fluid bed dryer machines have systems that help to minimize incidences of electrostatic charge.

Steps of fluid bed dryer working mechanism

To give you a clearer image of the working mechanism of a fluid bed dryer, we are going to outline the step-by-step procedure of everything that takes place in this machine.

But before the fluidized bed dryer is even turned on, the air compressors are inspected to ensure that they are in perfect working condition. Also, the heating system is turned on to war up the main chamber.

Step 1: Loading of the materials

The very first step entails loading the materials into the fluid bed dryer. Here a batch of the wet powder and wet granules is directed into the main feeding chamber of the fbd pharma machine.

The movement of the materials into the chamber is facilitated by the pressure difference between in and outside the chamber. Pressure in the main tower than that in the feeder. This means that the materials will be sucked into the high-pressure zone.

Step 2: Air is directed to the main chamber

The second critical step of the process entails pumping a stream of air into the FBD heating chamber. Here, you simply need to turn the blower on and it will pump pressurized air into the chamber.

You will use the controller to regulate the speed and the pressure of the air that is flowing to the chamber.

Step 3: FBD Fluidization

In this step, the granules are transformed into a liquid-like state by passing a stream of gaseous material over them. This air flows at a high velocity creating space between the granules. This ensures that the maximum surface area of the granules is exposed to high heat.

The fluidization process is fast and turbulent to maximize the disintegration of the particles.

Step 4: Drying

The drying process commences immediately after the fluidization process. Drying occurs at three distinct stages and each stage has a specific temperature of operation. You can control or regulate the temperature using the FBD controllers.

During the drying process, the fluidized granules are suspended in a stream of dry air. The moisture that is embedded in the particles will evaporate gradually leaving you with dry particles.

The video below gives an illustration of the drying process in a Senieer fluid bed dryer

From the drying stage, the fluid bed dryer is quickly adjusted to the preheating stage. Here, the temperature in the fluid bed is high and the rate of drying is constant. The high temperature in the chamber is mainly due to the evaporating moisture.

This moisture that has evaporated does not remain in the chamber. Instead, it is sucked through the pores. The drying will be complete after the moisture level in the chamber is extremely low.

Step 5: Shaking the filter bags

In some cases, the air pumped by the blower into the chamber may contain some fine particles. These particles are screened by pores of the filter bags. Excessive accumulation of the particles may clog the bag causing a massive drop of pressure in the fluid bed dryer.

To save the situation, the filter bag is mechanically shaken at specific intervals. Pneumatic cylinders do the shaking and this alienates the dust particles from the pores.

Step 6: Discharge of the dried granules

At this point, you are fully satisfied by the level of drying that the materials have achieved. The next task is to harvest material and use it for the next production stage.

The manual method has been used as an ideal discharge method for the old machines. The materials are offloaded from the fluid bed dryer and loaded to the next container manually.

For advanced machines such as Senieer fluid bed dryers, the discharge is done automatically through the vacuum conveying. Differential pressure is again used to control the flow of particles from a high-pressure zone to a low-pressure direction.

Chapter 4: Fluid Bed Dryer Parameters and How They Affect the Product

You may have the best fluid bed dryer but still, end with low-quality products from the drying process. Maybe the material did not achieve the level of drying that you have always wanted.

Several factors might have contributed to the poor performance of your FBD dryer for pharma. The most probable suspect is the failure to manage the performance parameters of the fluid bed dryer.

An FBD is a machine that uses specific parameters to drain moisture from the material. A failure of one or two parameters will degrade the quality of drying.

Here are the key FBD pharma parameters that will affect the quality of the final product;

Shape and design of the equipment

The physical outline of the fluid bed dryer will have a direct impact on the quality and nature of the dried grains and granules. Perhaps this explains why fluid bed dryers come in different shapes and design styles.

One of the things that are affected by the design of the container is the distribution of the materials inside the container. The design should allow even distribution for the maximum drying of the materials.

The shape may also have an impact on the velocity of the air that flows in the dryer. Poor design can hamper the velocity and this will also degrade the quality of the product.

At Senieer, we take the issue of shape and design seriously. This is why our FBD pharma machine has an annular and agile design that facilitates maximum drying of the material.

Also, you have the freedom to request the custom design of the fluid bed dryer. Here, we will design and shape the fluid bed dryer containers according to your specifications. At the end of the day, the customized shape should not have any negative impact on the quality of the drying process.

The position of the air distribution plate

The function of the air distribution plate is to facilitate the flow of dry air into the fluid bed dryer. It has pores that allow the air to flow in and heat the grains and granules.

The position of the plate matters when you are assessing the performance of the fluid bed dryer. The positioning should be able to allow all the air to be filtered through the plate. It should also preserve the pressure at which air is flowing through.

When it comes to positioning, the plate should be positioned close to the blower. This helps to prevent the loss of air pressure.

In addition to the position, the angle of the installation also matters. A slight misalignment of the distribution plate will interfere with the smooth flow of the pressurized air.

Confirm with the manufacture’s manual for the right positioning and perfect angle when installing the air distribution plate.

Operational pressure

From the working mechanism of the fluid bed dryer, we stated that dry air flows at a high velocity. This air is pressurized to move at that speed.

The PSI of the airflow has a direct impact on the level of drying henceforth the quality of the product that you will get from an FBD dryer for pharma.

High pressure will speed up the rate of fluidization. The materials will dry fast, smoothly, and uniformly. The reverse is true when the FBD machine operates under low pressure.

This happens because an increase in pressure will result in a significant expansion of the particles hence more exposure to the heat.

The good thing about this parameter is you can easily control it. The control feature of the FBD allows you to adjust the pressure accordingly.

Also, the air pressure should be constant for the effective performance and uniformity of the material.

Operating temperature

Temperature is a key parameter in the operation of the fluid bed dryer. It determines both the quality of the dried material and the rate of drying.

The right choice of the fluid bed temperature will ultimately result in high-quality material. Keep in mind that different materials require different levels and rates of drying.

The good thing is you can easily control the bed temperature by using the controller. Ensure that the temperature that you select matches the material and product requirements. This helps to prevent incidences of overheating. The materials. Also, you will achieve minimal drying if you choose low operational temperatures.

Humidity

The humidity in the FBD pharma machine will end up affecting the time that it takes to dry the materials and also the quality of the product. Humidity refers to the level of moisture content in the FBD main container.

Ensure that the humidity in the FBD is as low as possible as this will speed up the rate of drying. The High-end Senieer fluid bed dryer has sensors that will let you know the level of humidity in the machine. You simply use the controller to adjust the machine accordingly. Monitor the humidity before and during the drying process.

Moisture content in the product

Usually, the materials such as granules enter into the fluid grain dryer when they are wet or contain a certain percentage of moisture content. Some materials have a high moisture content while others have a low content of moisture.

The performance of the fluid dryer and the quality of the products will largely depend on the percentage of moisture in the product. Of course, this is in conjunction with the other key parameters that determine the operation of the FB dryer for pharma.

High moisture content can lead to the degradation of the product quality. This is usually the case if you do not select the right temperatures and pressure. Otherwise, pope selection of these control parameters will still result in quality drying.

Particle size and shape

The physical properties of the particles will have a direct impact on the quality of the final product. Some materials have large-size particles while others have small-size particles. How the fluid dryer will handle these particles will determine the level of drying that you will be able to achieve.

Ensure that you choose the right settings that will guarantee the best results for your particles. You can do all these using the controller of the fluid bed dryer.

Chapter 5: Types of Fluidized Bed Dryer

Fluid bed dryers are not all the same. We have different types of fluid bed dryers for sale. They come in different designs, constructions, and other technical specifications. You should expect different levels of performance from different fluid bed dryers for sale.

Let’s have a brief look at the main types of fbd pharma machines. At the end of it, you will be able to select the best one that will fit your manufacturing needs.

Conventional fluid bed dryers

As the name suggests the fluid bed dryers that belong in this category have been used for ages. They tend to rely on old technology to dry different materials. They have minimal modern features that enhance the convenience of using the machine and also improve the quality of the products.

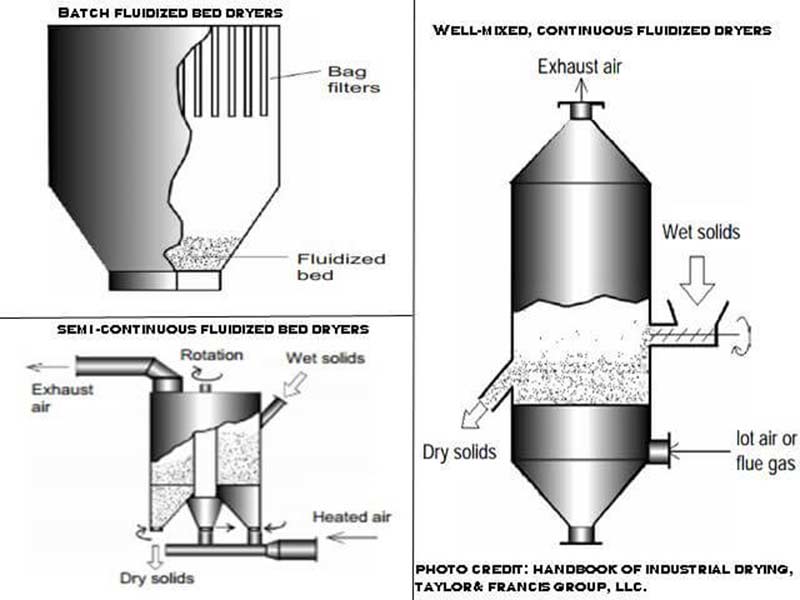

Conventional fluid bed dryers are further divided into smaller categories which include;

Batch fluid bed dryer;this type of conventional FBD executes the drying operations in batches. This simply means that materials are fed into the drying chamber in different batches. The next batch is allowed only after the previous batch has been extruded from the dryer. A PLC control is used to control the activities in the batch drying process. Batch FBD pharma dryers are designed to cut the cost of energy consumption. They are also ideal when you want to vary the volume of the materials to be dried.

Continuous fluid bed dryer:This is a type of fluid bed dryer in which the granules flow continuously through the drying chamber. They don’t stop at any given point so that they can be dried and another batch to be allowed in. This type of fluid bed dryer is highly optimized for performance. This is the surest way to ensure to achieve uniform drying of the materials. The main advantage of continuous fluid dryers is they are cost-effective. They are cheap to maintain and tend to last for long. These dryers also help to save time for drying.

Semi-continuous fluid bed dryer: This is the type of drying where the material is simultaneously charged and discharged from the fluid bed dryer. However, the drying process continues for a defined period. These machines are ideal when you want to vary the volume of the materials to be dried. The machines tend to utilize the best features of continuous dying and also plug some features of batch processing.

Plug flow fluid bed dryer ( PFFBD): This is among the oldest types of fluid bed dryers that have dominated the pharma and chemical industries. It is used on both grains and soluble products such as salts and ions. The method utilizes the dispersion theory especially in applications where there is no ideal flow of material. It is called plug and flow because it can predict the desired level of moisture content that the final materials should have and also the dimension of the products. It will then operate within specific temperature ranges to be in line with the predictions.

Well-Mixed continuous fluid bed dryer: These are continuous fluid be dryers that tend to have special designs to accommodate specific types of materials. They are mainly used for drying hygroscopic materials. These are materials that absorb water moisture and condense. The drying time for such materials is perfectly curated so that they don’t end up condensing. The dryer is also designed to meet the unique characters of the hygroscopic compounds.

As you can see, most of the conventional fluid bed dryers are multifunctional-they are designed for drying different types of materials and can be used in different industries. They can also perform different tasks on the materials and compounds.

The main disadvantage of the conventional fluid bed dryers is they may not offer desired performance on unique products. This is mainly because they are not customized for specialized drying conditions.

Modified Fluid bed dryers

Conventional fluid bed dryers are used for the general drying requirements. What if your business line or manufacturing field provides a unique set of challenges? This is where you may consider getting modified fluid bed dryers.

As the name suggests, these dryers are designed to meet unique challenges that conventional dryers are not able to overcome. The manufacturers take the step of tweaking the designs and performance features of the dryers according to the specifications of the clients.

Sometimes the modification may require additional components that are not on the conventional fluid bed dryer. Technological advancement has made it easy for fluid bed dryer manufacturers to come out with an array of modifications.

The brain behind the modified fluid bed dryers is to improve the quality of the materials while at the same time enhance the convenience of using the machine.

Here are the most common types of modified fluid bed dryers for sale;

Spouted fluid bed dryer:These fluid bed dryers were invented to minimize the loss of materials that are usually recorded at the drying stage of production. It is mainly used on coarse grains. These dryers can dry large particles that have high moisture content in them. They also have an efficient energy consumption rate as compared to most FBD dryers for pharma. They are commonly used in the food and beverage industries.

Heat pump dryer:As the name suggests, this type of dryer works together with a heat pump. This is to imply that heat is pumped in a loop of the machine to affect the drying process. The heat energy then heats the air which will in turn heat the granules to reduce the moisture content. This type of modified FBD is designed to minimize the loss of heat energy from the machine. This will eventually cut down on the cost of running the fluid bed dryer.

Mechanically assisted bed dryer:This type of fluidized dryer works by blowing heated air through the grains and granules. This is done repeatedly until you achieve the desired level of dryness. It is referred to as mechanical because the operator controls the rate at which air is blown through the dryer. Unlike other fluid bed equipment, this one is devoid of sophisticated parts and components. Instead, it has very basic features and components. The main problem with this type of fluid bed dryer is slower than other fluidized dryers. It is also less accurate as you may have to manually check the level of drying that the materials have achieved.

Swirl fluidizer:Swirl fluidizer is commonly used in the food and cosmetic industry. It is well-suited for drying paste-like products. The working mechanism of the aeromatic fluid bed dryer makes it capable of handling different weights and densities of material. Such materials are known for being viscous.

Vibrated fluid bed dryers:Also known as vibrating fluid dryers, they are designed for materials with large particles. The dryers have a vibrating mechanism that allows a stream of hot air to penetrate through the dryers. This type of modified fluid bed dryer is also ideal for the stickY and temperature-sensitive materials.

Hybrid fluid bed dryers: These modified fluid bed dryers incorporate a heat pump mechanism to completely dry the materials. The combination helps to speed up the rate at which the granules dry. It also helps to preserve the quality of the materials. These fluid dryers are mainly used for sensitive materials thanks to their enclosed designs. They are also energy-efficient as they minimize heat loss from the system. Their main issue is they can only be used on a limited range of materials.

Pulsating fluid bed dryers: Some materials tend to be cohesive when wet. They form a solid material and it will be difficult to separate them. Such materials cannot be easily subjected to the fluidization process. A modified fluid bed dryer is used in such cases. Pulsating fluid bed dryer will create kinetic curves which will lead to the fluidization and dry the materials. The dryer can achieve this goal without degrading the quality of the material.

So, which type of fluid bed dryer are you going to buy? If you are going for the convention fluidized dryer, you have plenty of options to choose from. The same applies to the modified fluid bed dryers. Simply compare your needs and find out the right type from the fluidized bed manufacturer in China.

Chapter 6: Factors to Consider When Buying a Fluidized Bed Dryer in China

At this point, you have mastered enough courage and confidence to buy a specific type of fluid bed dryer. But before you go ahead and get the fluid dryer, here are some of the key guidelines that can help you choose the right fluid bed equipment;

1. Fluid bed dryer production capacity

This refers to the volume of the materials that the fluid bed dryer is designed to handle at any given time. Fluid bed equipment for sale come in a different capacity. Some are designed to handle large volumes of materials while others have a low handling capacity.

Choose the fluid bed dryer whose capacity matches your business needs. This is to imply that you should get a high-capacity pharma FBD if you intend to dry large volumes of the material.

The capacity of the fluid bed dryer is directly proportional to the product container of the equipment. The larger the container, the more the handling capacity of the fluid bed dryer. It will have more space to contain the granules and other materials.

2. Rate and volume of the airflow

As we have seen a stream of dry air is used for drying materials in the fluid bed dryer. The volume of the air that is conveyed into the dryer and the speed at which it passes through the materials matter.

Find out the rate at which the fluid bed pharma machine is capable of allowing air to flow through the materials. A high rate of flow means faster and quality drying. You can easily find this information by reading the FBD specification. The volume and rates are usually denoted in terms of m3/min. For example, the fluid bed dryer may have 0.8m3/min.

3. Power consumption of the fluid bed dryer

It is critical to verify the wattage of the fluid dryer bed equipment that you are planning to buy. This will tell you whether it is a heavy consumer of electric energy or it conserves power.

Start by verifying the power delivery fluid bed dryer. This will determine the delivery and expected output of the FBD equipment for sale. The fluid bed dryer can be rated as 2Kw or 10KW. A high power rating is associated with exemplary performance.

Other than the performance, it may also be expensive to keep a powerful fluid bed dryer. You may opt for the less powerful FBD pharma equipment as it will not attract a high energy bill.

4. Fluid bed blower specifications

The work of the FBD blower is to pump dry air into the fluid bed chamber. This is the air that will be responsible for drying materials. It is advisable to inspect the blower to ensure that it is designed to deliver the best blowing performance.

Even though the volume of the air blown depends on the specs of the fluid bed dryer, the design of the blower can also have an impact. For instance, will the blower allow all the air to pass through it when the FBD is operating at maximum capacity?

Also, take note that there are different types of blowers for the fluid bed dryers. Choose a type of blower that will be suitable for delivering the best job in your industry. Blower specs such as blades and flow capacity are just some of the key pointers that can help you select the right fluid bed blower.

5. Consider the physical dimensions of the fluid be dryer

Just like when buying any major machine, you should consider the relevant dimensions of the equipment. A fluid bed dryer is not an exception. The dimensions will help you know whether the FBD pharma will perfectly fit your premises.

Check out the length, width, and height of the fluid bed dryer. Will it fit in the room in which you are planning to do the installation? What about the weight? Find out the approximate weight of the fluid dryer machine that you are planning to buy.

The dimensions of the fluid bed dryer also play an important role when it comes to the ease of handling the equipment. You wouldn’t want an extremely heavy and large FBD machine as it will be less convenient to handle and operate.

6. Fluid bed dryer spray mechanism

How is the material spayed into the chamber? This is what we mean by the fluid bed dryer spray mechanism. The spray mechanism is mostly determined by the working mechanism of the fluidized bed dryer that you are planning.

The most common spray mechanisms for the fluid bed dryer include the top spray mechanism, bottom spray mechanism, and tangential spray mechanism. As you can tell the mechanism is mostly defined by the direction of the spray.

You may also consider adjusting the position of the fluid bed dryer nozzle so that its spray mechanism may suit your production needs.

7. Cost of the fluid bed dryer

There are different aspects of the cost that you have to consider when buying a fluid bed dryer. One of them is the price of a fluid bed dryer. Since fluid bed dryer manufacturers stock different machines at different prices, you will have to compare the price of each machine.

Thereafter you will choose the FBD pharma machine that you can afford. In most cases, the price will depend on the specifications of the fluid bed dryer and as well as the manufacturer of the FBD machine.

Another aspect of FBD price that you have to consider is the cost of running and maintaining the fluid bed dryer. High-performance FBD will attract high running costs since they tend to consume more resources such as electricity.

You cannot avoid pertinent issues such as repair and maintenance costs when doing your cost analysis for the fluid bed dryer. Can the fluid dryer be easily repaired and maintained when needed or will you have to pay a high price for these services?

Once you are comfortable with the cost factor, you can proceed to buy your fluid bed dryer in China.

8. Fluid bed dryer control system

Fluid bed dryers come with different control systems. Find out the control capabilities of your FBD for pharma before buying.

Most buyers are inclined to buying FBD pharma machines that will give them maximum control features. You should be able to manage the key control parameters such as temperature, a flow rate among others.

9. cGMP compliance

Do your due diligence and find out whether the fluid bed dryer that you want to buy complies with various international standards. One of them is cGMP.

Compliance is a sign that the fluidized bed dryer machine is of high quality and can be used for food and drug applications.

Once you consider all these factors, you can confidently go ahead and choose a fluid bed dryer that meets them.

Chapter 7: Applications of Fluidized Bed Dryer

Where can I use a fluid bed dryer and for what purpose? Senieer fluidized bed dryer is used for drying different materials such as grains, granules, and powder. Here are some of the most prolific application areas of this fbd pharma machine;

- Pharmaceutical industry; Companies in this field are involved in manufacturing drugs and medicinal products. The materials for making solid dosage forms such as tablets and powders are usually dried. The wet fluid materials must be dried before it is subjected to any further processing.

- Fertilizer manufacturing: Agriculture is another industry that witnesses the use of fluid bed dryers.The granules and pellets are first dried before being packaged and sold.

- Food and beverages: The process of food and beverage preparation may entail drying the ingredients.

- Nutritional products: Nutritional supplements such as proteins and energy powders are usually subjected to a drying process before they are packaged.

- Pesticides and agrochemicals

- Detergents and soaps

- Waste management and recycling

Chapter 8: How to Choose Fluidized Bed Dryer Manufacturer

So you are in the market looking for the best fluid bed dryer for sale? You will get offers from different manufacturers and suppliers. Some will have the best equipment while others make average or low–quality FBD pharma machines.

What can you do to end up with the best fluid bed dryers? The secret is to choose the best-fluidized bed manufacturers and suppliers in China. Here are some of the effective tips that you can use when vetting and selecting fluidized bed dryer manufacturers;

Experience of the manufacturer

How long has the fluid bed dryer manufacturer been in the pharmaceutical industry? Their experience in this field is directly proportional to the quality of products that they supply.

In most cases, we are wired to buy from the most experienced FBD pharma equipment manufacturers. This is mainly because they can leverage their experience in this field to develop the best equipment.

It will be prudent to directly inquire from the manufacturers or suppliers about the number of years that they have been in the business. However, this alone should not be the basis of you choosing a manufacturer and disqualifying another.

Manufacturer’s production capacity

Does the manufacturer have what it takes to deliver the best FBD pharma machine? The only way to find out this is by assessing the capabilities and capacity of the FBD pharma equipment manufacturer.

Collect key details such as the kind of technology used by the manufacturer and the staff that they have. The surest way of getting this information is by visiting the facility. This way you will get first-hand information about everything.

Company compliance with international standards

When looking for a pharmaceutical machine such as a fluid bed dryer, you should first verify whether the manufacturer fully complies with the relevant international standardization bodies. These are organizations that are responsible for regulating the production and manufacturing of this equipment.

Find out whether the FBD equipment manufacturer is FDA, cGMP, and other relevant standards. Working with a compliant manufacturer will assure you of the quality of the equipment that you are about to buy.

Post-sale customer service

After buying the fluid bed dryer in China, will the company accord you the relevant support? For example, if the FBD pharma machine breaks down, will the company help you manage issues such as repair and avail the parts?

Find out the kind of support that the manufacturers give. You will have peace of mind when you know that the manufacturer has your back. Other aftersales services that you may inquire about from the manufacturer include warranty and technical support.

Fluid bed dryer reviews

This is the ultimate tool that you can use to compare and find the best fluid bed dryer manufacturers. The reviews will give you quick insight into what to expect from the manufacturers.

Take your time to read through online reviews about the manufacturer. Many negative reviews could be a sign of trouble ahead. They could mean that the manufacturer has low-quality equipment or poor customer service. On the other hand, positive reviews are a sign of a reputable fluid bed manufacturer.

Chose FBD manufacturers in China

The country where you buy the fluid bed dryer matters. China is usually a recommended company when it comes to heavy-duty pharma equipment such as FBD.

China is among the most technologically advanced companies in the world. You can be sure of getting the most advanced fluidized bed dryer machines here. Also, most manufacturers in this country strive to provide the best FBD equipment.

So, choose the best-fluidized bed dryer companies in China and you will not regret it.

Chapter 9: Frequently Asked Questions about Fluidized Bed Dryer

At this point, I hope that you have acquired some valuable knowledge about fluid bed dryers. However, it is normal that you may need some clarifications about Senieer fluid bed dryer. We will try to answer them as below;

What does a fluidized bed mean?

A fluidized bed is a process in which solid materials such as grains and granules are subjected to different conditions so that they form fluid-like substances. The process usually entails mixing solid and fluid b materials.

Can I get a customized fluid bed dryer?

Yes. If you don’t want a stock FBD or the ones that are already manufactured, you can place an order for the customized FBD. As the best fluid bed dryer manufacturers in China, we will customize the machine according to your requirements. You simply need to give us the details of your requirements and our design team will embark on the customization process.

What is the principle of the fluid bed dryer?

Fluidized bed equipment operates on the principle of fluidization. Here, static solid materials are converted into a semi-liquid state. A stream of hot gas is then blown through this material through a perforated plate. As it does so, it carries along with it the moisture that had been embedded in the material. Keep in mind that the gas moves at a high velocity.

What are the disadvantages of a fluid bed dryer?

In as much as a fluidized bed dryer may appear to provide a perfect solution to your drying needs, some drawbacks are associated with buying and using this pharma machine. Here are some of them;

High cost of the fluid bed dryer

Some users complain that the price of a fluid bed dryer is too high for them. In terms of comparison, fbd pharma machines are more expensive than most traditional methods of drying.

While the price of fluid bed dryers may appear to be high, the benefits that you are likely to gain from this machine are more than the cost involved. For instance, the machine will save you from incurring heavy losses during the production process.

Also, Senieer designs and manufactures affordable fluidized bed dryers that you will ever find in the market. Take your time to see what we offer and you will debunk this myth.

Electrostatic charge

The process of fluidization can lead to the generation of electrostatic charges on the particles. This may force some particles to stick to each other as others stick to the walls of the fbd in the pharma drying chamber. The good news is Senieer fluid bed dryer is designed to minimize the effects of electrostatic charges on the particles.

A wet feed can lead to poor fluidization

In some cases, the fluid bed dryer feeder may be wet and this will affect the material that is passing through. Some materials may end up sticking on the feeder.

Senieer fluidized dryer is designed to ensure that the feeder is completely dry before it commences with the fluidization process.

Senieer: Reliable Fluid Bed Dryer Manufacturer in China

I hope that this guide will prove valuable in your quest for finding the best fluid bed dryer. At Senieer, we are proud of being among the most reliable fluid bed dryer manufacturer in China.

We pride ourselves on consistently supplying the best-fluidized bed dryers over years. Our experience in this industry speaks for itself.

All our fbd dryer equipment is modeled and manufactured with the best team. We are well-equipped to handle any task thanks to our able team and also advanced technology.

We strive to meet the deepest demands of our customers. Apart from the stock FBD machines, you can also place requests for customized fluid bed dryers.

Our contact lines are always open. Feel free to contact us or send a message and we will answer any queries that you need to know about fbd in pharma.