Co mill: Introduction:

Senieer offers high-quality co mill (conical mill, comill, cone mill) for the global market. The company supplies different models including movable comills, laboratory comills, and conical mills available integrated with high shear mixer granulator, lifting columns, etc.

This article seeks to introduce you to conical mills in general. You’ll get enough information to inform your next purchase decision.

Based in China, Senieer can provide compliant pharmaceutical automatic cone mills regardless of your country. And at very competitive prices!

So without further ado, let’s get started:

Chapter 1: Size reduction in the pharmaceutical industry

So what is particle size reduction?

It’s by far one of the critical processes in drug manufacturing.

It’s decreasing the size of larger particles that are in powder form to produce smaller particles. It can also make course particles finer. And help sort granules into the required sizes or grades.

And why is it important?

- It increases the surface area of particles

- Promotes dosage uniformity

- Improves the formulation’s dissolution rate and hence its absorption in the board.

- Boosts the bioavailability of the drug

- Size reduction also improves the powder’s flow, bulk density, and compactness

1.1 Co mill: size reduction in the pharmaceutical Industry

There are several techniques available for powder processing. In brief, we have crushing, milling, grinding, cutting, chopping, and micronizing.

Each of these processes is carried out by different machines. Pharmaceutical companies factor in several things when selecting a size reduction technique including the properties of the material, the size range of the final particles, friability of the raw materials, its heat sensitivity, among other factors.

Milling tends to be the most preferred particle size reduction method. It’s both applicable in R&D and full-scale production.

At its heart, milling just involves using shearing force/impact to reduce the sizes of large particles by breaking them up!

There are several types of milling equipment used in the pharmaceutical industry. We have:

- Ball mills

The ball mill consists of a hollow cylindrical/drum that is rotated about its axis. Inside the cylinder, there are small metal balls. The powder is fed inside the ball mill, and as it rotates the balls impact the bulky raw material.

An illustration of a ball mill Wikipedia

- Fluid energy mills

They are also called pulverizing mills. And they depend on the collusion of bulk raw particles with a stream of compressed air.

Usually, the milling takes place in a grinding chamber, at the bottom of which a nozzle is mounted. The disadvantage is that fluid energy mills have high energy consumption. On the plus side, they provide a very fine powder.

- Turbo mills/hammer mills

Hammer mills are fairly common. Their crushing chamber houses a shaft with knives mounted on it.

Bulk raw particles discharged inside the chamber come into contact with the rotating blade. Upon impact with the surface of the blade, large powder particles break into smaller pieces.

The rotating shaft can rotate at high speeds from 2,500rpm. There is a screen that allows particles of the desired size.

1.2 Co Mill or Conical Mill?

The cone mill is also called the conical screen mill. One of its distinguishable features is a cone-shaped chamber fitted with a rotary impeller/knife.

Materials are fed into the cone mill in several ways:

- Hand feeding

- Vacuum feeding

- Gravity feeding

Cone mills are highly flexible and widely used for intermediate sizing in wet and dry granulation processes.

So next, let’s talk about the functions carried out by the cone mills:

1.3 Roles of the cone mill performs in the pharmaceutical industry:

- Reduction of particle sizes – The conical sieve mill remains to be the most effective size reduction machines in the pharmaceutical industry.

- Deagglomeration – It’s the breaking up of particles that have agglomerated, aggregated, or clustered together.

- Sieving/screening – The pharmaceutical cone mill can be used for security screening. It’s the act of capturing any foreign substances to keep them from becoming part of the final product.

- Dispersion – It’s the action of distributing one material into another. Milling raw powder materials can also improve their dispersion.

- Milling wet granules before drying – When this is done, it increases the surface area of the wet material to facilitate faster drying.

- Applications of milling in other industries – Size reduction is a key unit operation in other industries namely the cosmetic industry, food, and fine chemistry. One example of a milling operation is reclaiming food substances such as biscuits by milling them into smaller particles.

With that, let’s look at the parts of the pharmaceutical cone mill:

1.4 Parts of the cone mill

The cone mill is a fairly easy machine to understand. Its parts include:

- Feeding hopper – It’s the cone-structure that holds bulk raw powder materials during feeding. But it might not be present where the cone mill is connected to a bin/IBC, or vacuum conveying equipment.

- Impeller – It’s the rotating part of the cone mill. And it consists of two or three blades. There are two common types of impellers; square-bar & round impellers.

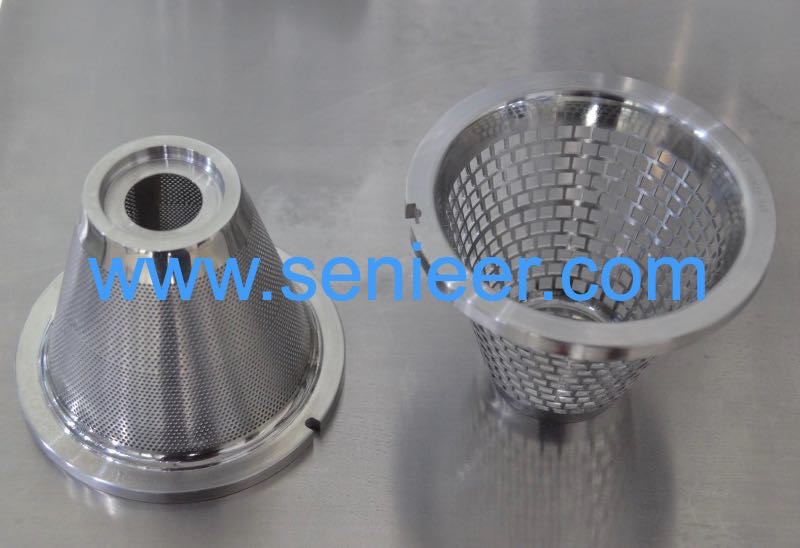

Square-bar impeller blades and mesh with round holes

- Mesh screen – The mesh screen is perforated with holes of different shapes.

- Drive system – The drive system is simply used to power the rotating impeller. There are several drive options including direct drive, belt drive, or gear-box drive. The drive system can be top, under, or remote/thru-wall.

- Frame & Base support – It can be a movable chassis or fixed base frame that anchors the cone mill to the floor/tabletop.

- Receptacle – It is a container that holds the finished powder grains after they’ve passed through the metal mesh screen. The receptacle can be connected to a vacuum transfer equipment for automatic conveying.

- Stainless steel surface – The cone mill’s mirror-polished surfaces are smooth and with a non-sticky finish.

- Seals – Either made from silicone or PTFE.

1.5 Working principle of cone mills

Understanding how the cone mill works is not hard. The milling process steps include:

- Materials are fed into the conical mill chamber through the in-feed chute. Feeding can be through gravity where an IBC bin/drum is interlocked onto the cone mill and inverted. When the butterfly valve is open, the powder particles flow into the conical mill.

- As the powder particles come into contact with the rotating impeller, they are broken up through shearing & attrition and flung against the perforated sieve.

- Desired grain sizes pass through the screen’s holes.

- Increasing the speed of the impeller can result in smaller granules since it flattens the approach angle of particles to the screen’s surface.

- Processed powder particles are collected in the receptacle, or vacuum conveyed to the next process equipment.

Forces acting on powder particles during milling #source

1.6 Co mill: types of sieves/screen type

Cone mills can utilize different screen types. And what distinguishes them is the shape of the holes:

- Round hole sieves – (Diameters of Ø0.5 up to Ø 3 )

Most conical mills utilize round hole sieves. You can use them with most free-flowing materials including granules & powders, it depends on your process requirements.

- Square holes – (Dimensions 3*3 to 10*10)

Square hole screens produce coarse particles. They are applied in de-lumping & de-agglomeration wet masses.

- Grater holes

Consists of holes that have been raised to create sharp cutting edges. Grater sieves can break down hard substances for instance tables during reprocessing and reworking operations. In food industries, grater sieves can grate sweets, tough seeds, etc.

- Consider hole

Consider sieves consist of a sheet with raised holes that are triangular-shaped or semi-oval.

- Slotted holes

Now, slotted holes closely match the stadium shape (a rectangle with two semi-circles at each end). Slots are larger than square holes. So they allow larger particles through the screen than do square holes.

Senieer screen types

We can supply three different kinds of screen meshes. These are the most commonly used screen types in many industries:

- Round mesh(used for dry cone mill)

- Square mesh(used for wet cone mill)

- Grater mesh(for the very hard granules)

1.7 Advantages of Cone Mills

Conical sieve mills are widely used due to their inherent benefits over other size reduction equipment.

Let’s go over their benefits, which include:

- The sieves and the impeller can be changed easily and quickly.

- The cone shape makes it hard for the residual powder to build up.

- They have some of the lowest noise level and low heat generation.

- Their versatility makes them suited for many industrial size reduction processes.

- Gentle milling leading to a low fraction of fines.

- Hygienic, since they are easy to clean.

- Produce uniform particle sizes.

- Have high-hourly capacities.

- Less labor-intensive.

- In-line vacuum conveying allows for high containment and protection of granules from damage as they are transferred from one process equipment to the next.

Video showing Vacuum conveying with Cone mill:

Chapter 2: Senieer’s Cone Mill Models

In this chapter, you’ll see some cone mill types offered by Senieer.

2.1 MTM Series Movable Pharmaceutical Cone Mill

MTM series conical mill with movable chassis

Thanks to the MTM series cone mill’s compact design, it is the ideal choice for new & established processing plants.

We designed it with versatility in mind and for easy integration in your existing line.

MTM Series Co mill: Features

It’s equipped with a hydraulic lifting system. The cone mill’s impeller is driven by an electric motor. It also includes a movable chassis allowing you to use it with several process equipment and in different rooms.

Its control panel or press button is also mounted on the trolley. And it offers maximum visibility for the operator for safe operation.

Different models for varying capacities

Senieer MTM movable conical sieve mills have different models including the:

- MTM 700 conical mill

- MTM 450 conical mill

- MTM 300 cone sieve mill

Our MTM series pharmaceutical sieve mill can supply outputs of 30Kg/h to 1000kg/h. And if you’re looking for a cone mill screen manufacturer, we can supply different sieve types as per your exact requirements.

Advantages of the MTM series cone mill

- Applicable to wet & dry granulation processes

- Meets cGMP recommendations

- Offers a high level of product safety with the best material used for seals ensuring high-level containment

- Easy to use and oriented towards operational safety

- It is simple to clean with Washing-in-Place. Smooth stainless steel surface has no protruding screws

- Uniform rotary motion with constant speeds and force

- Produces even grain-sizes and it is easy to control sizes of the final particles

- Comes with variable speed control

- Contact parts are mirror polished. You can also autoclave the contact parts during sterilization.

- AISI 316 for contact parts and non-contact sections use AISI 304.

2.2 MTMS Laboratory Cone Mill

The MTMS lab cone mill and table lab cone mill is the ideal choice for research and development activities. We have supplied it to pharmacy colleges and equipped several pharmaceutical labs with our MTMS cone mill.

This self-contained cone mill has a movable trolley.

MTMS Laboratory Co Mill : Advantages

- Ergonomic handles for easy movement

- AISI 316 for contact parts and non-contact sections use AISI 304

- Suitable for small spaces and is easy to store

- The design meets cGMP regulations

- Suitable for use on tabletops with fixed support available

- Atmospheres Explosives (Ex-proof) model available as an option.

- Low maintenance

- Frequency inverter installed to adjust the rotation speed

- Competitive price

- Low heat and dust

- Top-notch PTFE seals

- Quick screen change and compatible with different sieve designs

Learn more about Laboratory MTMS Comill.

Chapter 3: Co Mill: Manufacturers

Choosing China Cone Mills for your pharmaceutical, food, cosmetic, or fine chemical industry comes with several benefits.

First, you are assured of optimal quality when you partner with an experienced and reputed company.

At Senieer, we have been offering pharmacy machines and technical support to pharmaceutical industries for over 30 years.

Second, you access the most competitive prices!

Our company can keep our pharmaceutical cone mill prices relatively lower than other suppliers because we make each machine at our factory. No subcontracting.

We have an in-house team of highly specialized technicians. And in the course of doing business for many years, Senieer has forged good connections with electrical parts suppliers, raw material suppliers, etc.

Helping you find your next cone mill & Turnkey solutions

Senieer will ensure that you buy the most suitable cone mill based on your needs, and properties of your raw materials such as:

- Hardness

- Desired particles sizes

- Dry or wet granulation

- Chemical properties

- Moisture content

Get a free consultation with our knowledgeable team. We’ll take time to evaluate your needs, and take into account any feedback.

Senieer’s ultimate desired is to equip you with efficient and effective products. And to forge friendly relationships based on mutual benefit.

Want to Buy or Order a Co mill ( Conical Mill ) then Wait?

Achieve great results with our long-lasting size reduction equipment. Just send us an inquiry today. Our manager, Nikki Zhu will respond in the shortest time.

Contacts:

WeChat: nikki201222

Phone: +86-23-67668887

Skype: +8613637787586

Email: sales@senieer.com

You can also visit our factory in China. Talk to us to arrange a visit.

Resource: