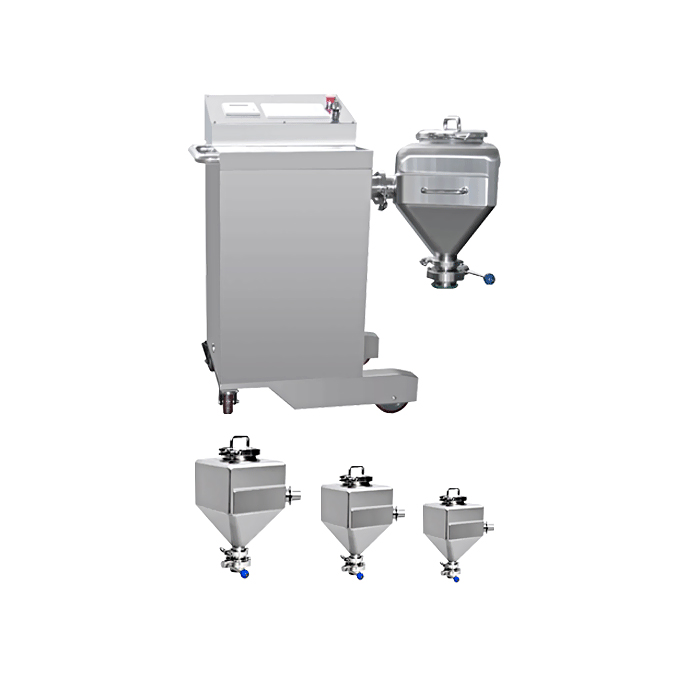

BDV IBC Bin Blender

- IBC bin is interchangeable with different specifications

- IBC bin blender with the infrared safety device

- Reasonable structure design, stable performance

- Simple operation ensure safe and reliable production

- Equipped with discharging butterfly valve to avoid misoperation

- It is provided with the multiple safety interlocking mechanism

- IBC blending system intelligent PLC control and graphical HMI

- It is provided with built-in automatic fault self-diagnosis system

- Flexible to transfer the materials with trolley IBC bin

- Mixing time and rotating speed adjustable through touch screen

- Inner and outer surfaces are all polished to high quality

- IBC bin system auto position, auto record printing, failure report and alarm

- Interchangeable IBC bin suitable for various kinds of materials

- Automatically finish all actions such as clamping, lifting and mixing, ect

- Ideal to the FDA/cGMP standard

Your Premier BDV IBC Bin Blender Manufacturer

Senieer BDV Series IBC Bin Blender is also named BDV Series IBC Blending Systems. Bin mixer is most popular solid powder mixing equipment field, having advantage of high homogeneous mixing, high material loading rate, movable IBC bin greatly facilitate loading, mixing, unloading and cleaning, it is also able to connect with upstream and downstream equipments to form a solid granulation line, which effectively avoid dust and cross contamination by repeatedly material change-over. BDV Series IBC Bin Blender can meet the mixing requirements for large batches and diversified varieties of products.

Senieer BDV Series IBC Blending is lifing type rotary mixer. It consists of base, rotary frame, driving system, lifting system and lowering system, braking system and PLC control system. It can automatically fulfill clamping lifting and rotating. When it works, push the IBC bin into the rotary frame. Press the confirm button on the touch screen. The IBC bin is lifted to the required height and clamped automatically. The drving system will begin to work and mix according to the required time and speed. When reaching the required extent, it will stop working. Then the lifting system lower down mixing bin and stops at the stated height. Pull the bin out, the mixing cycle is finished and will type the entire data of mixing process.

Senieer as a premier IBC Blending Systems supplier and manufacturer, custom any IBC Bin Blenders for your detailed application, equipment ideal to the FDA/GMP standard with fully intelligent PLC control and graphical HMI. IBC bin blenders with the infrared sensor, ensure safe and reliable production, Senieer BDV Series ibc blending system guarantee homogenous blending of granules and powder.

Senieer BDV Series IBC Bin Blender are usually used for homogenous blending of granules and powder. When you decide to the capacity of IBC Bin blending you need, we will design the best drawing for your layout. As a professional BDV Series IBC Bin Blender manufacturer in China, we want you and all our customers to be satisfy with our equipments, if you are happy, you will introduce our BDV Series ibc blending to more customers you know. If you have aroused your interest, please get in touch with Senieer now.

- Send Inquiry