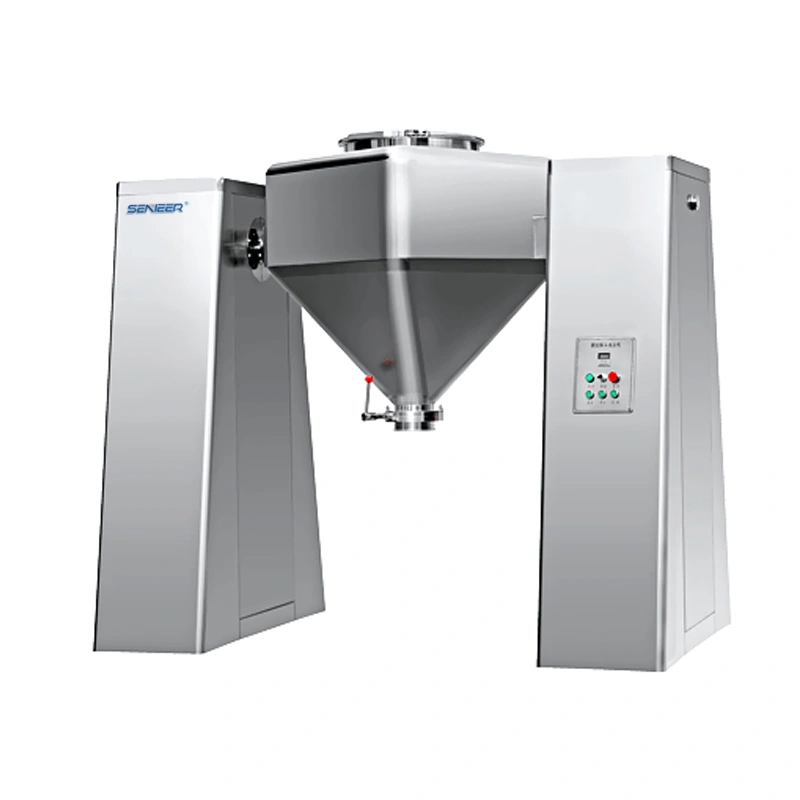

Current Product: IBC Blender

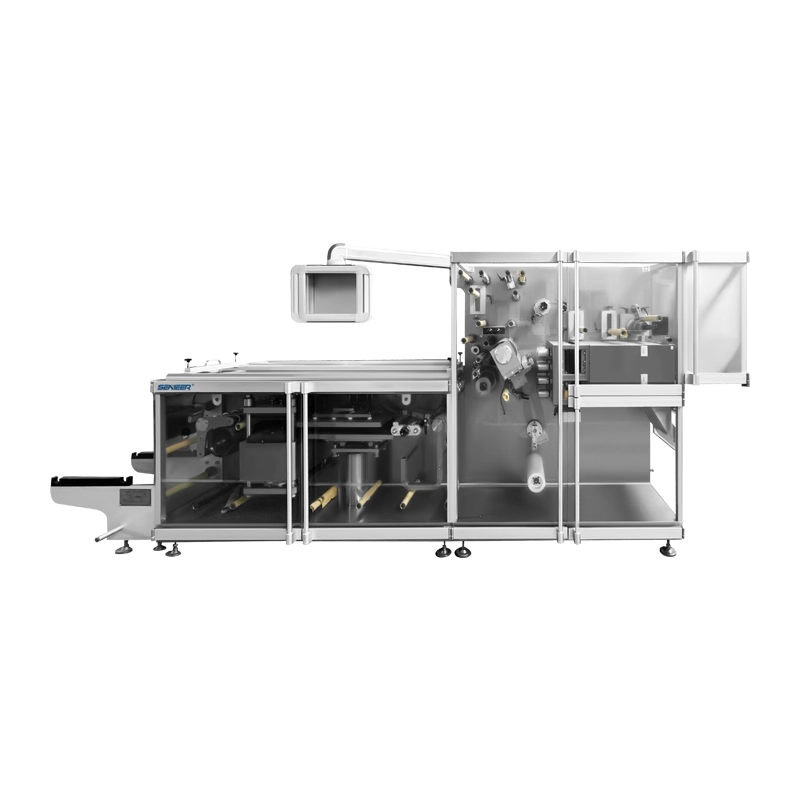

Senieer cone valve IBC blender is the updated version of previous blenders and mixers. After many years of manufacturing experiences and research, we successfully developed new generation of IBC blender with cone valve technology. The volume of IBC containers can be custom designed according to client’s needs, ranging from 300 to 3000L. It is easy to clean by manually or automatically.