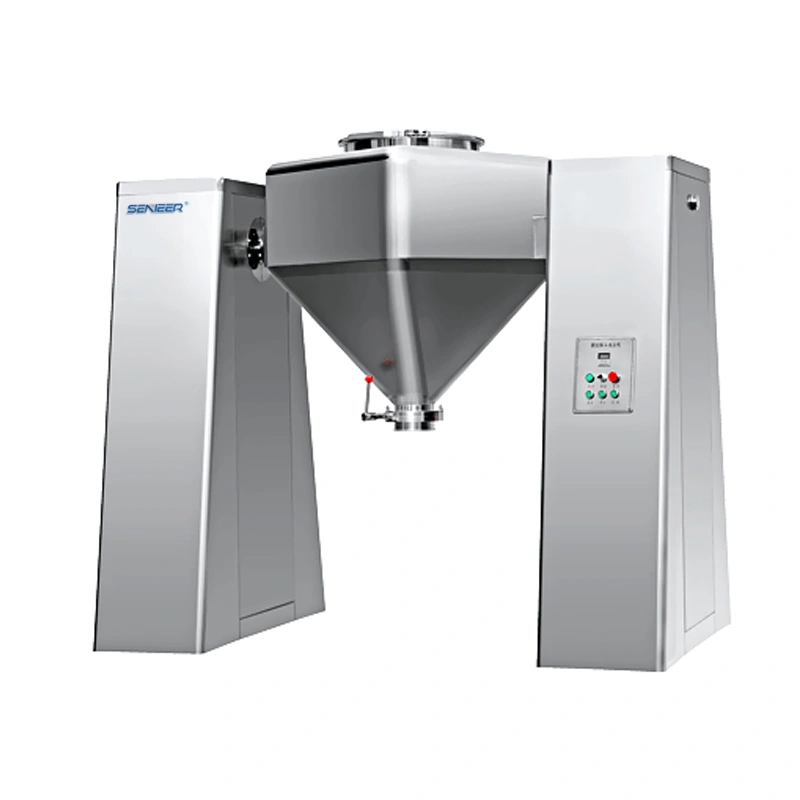

Current Product: Post Bin Blender

Our post bin blenders have passed international quality system certifications (such as CE, ISO) and are sold well in global markets including Australia, the UK, South Africa, Canada, and Turkey. With the advantages of compact layout, stable operation, and high mixing uniformity, it effectively meets the production needs of batch mixing of powder and granular materials, and is favored by enterprises pursuing efficient and clean production.