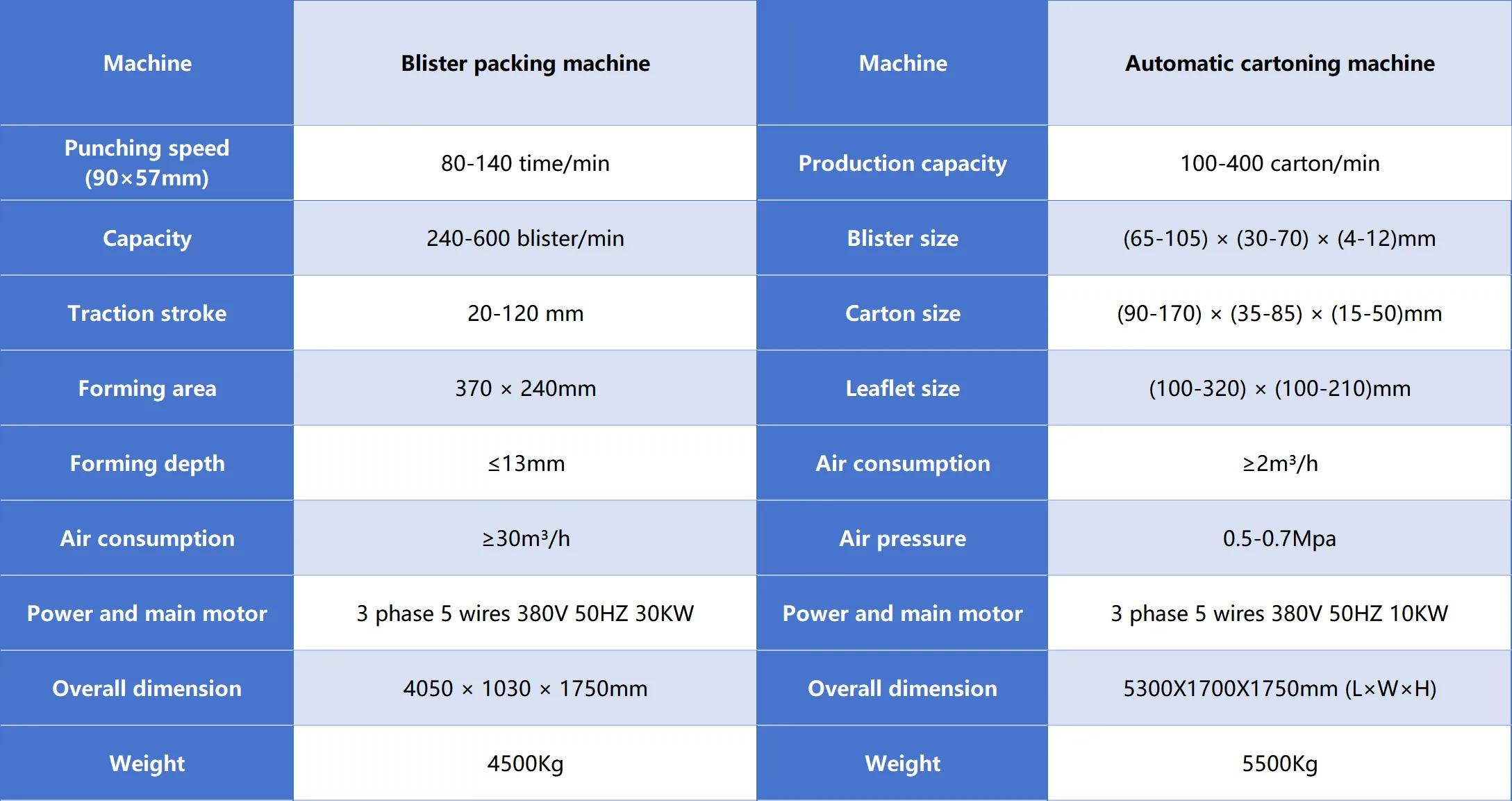

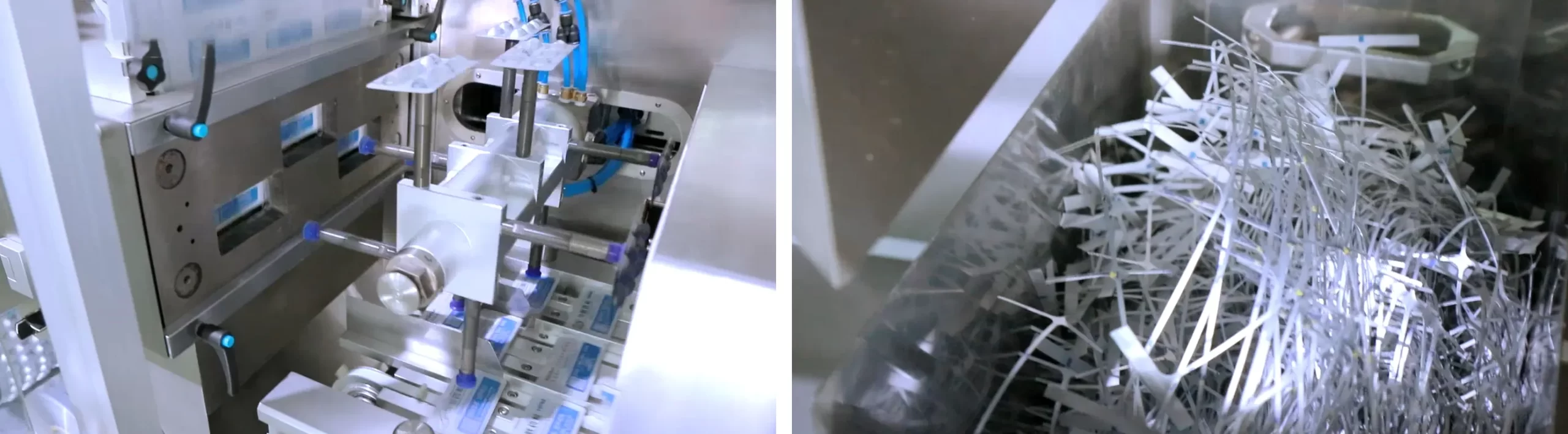

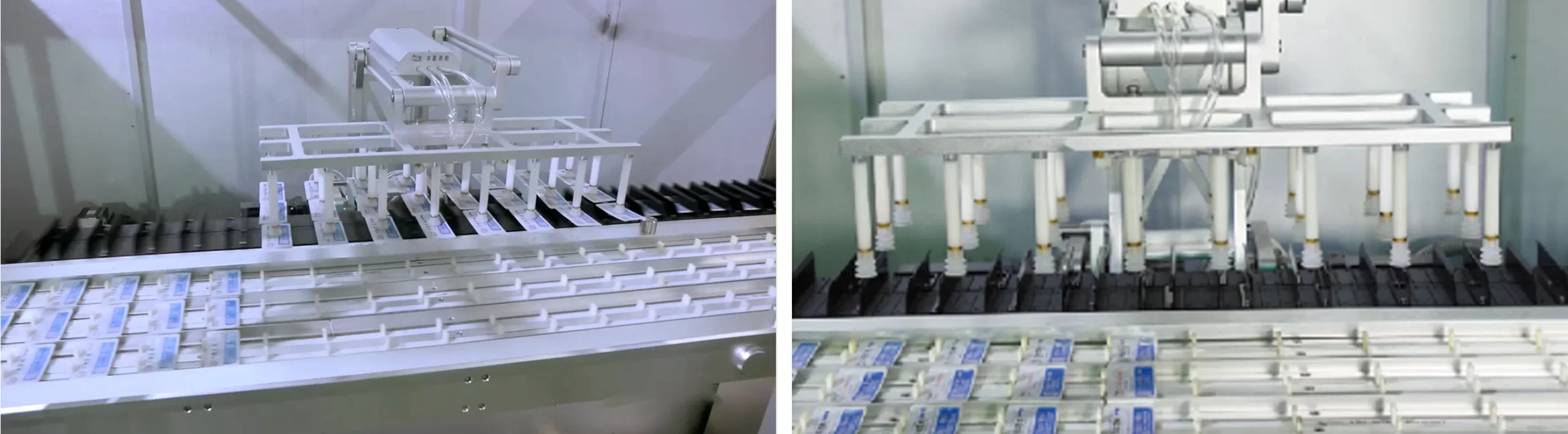

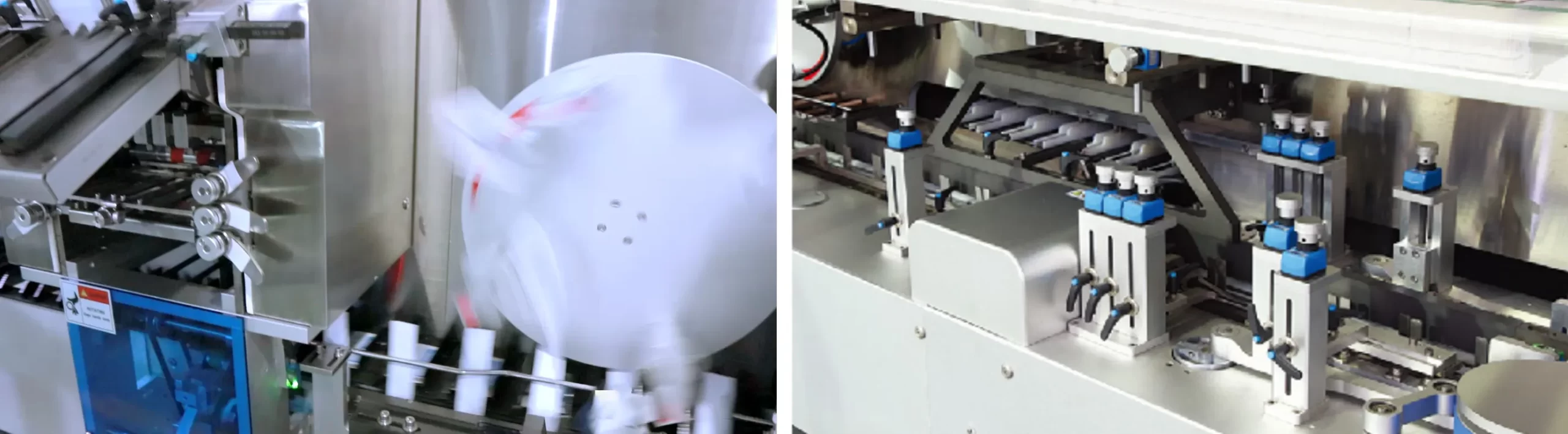

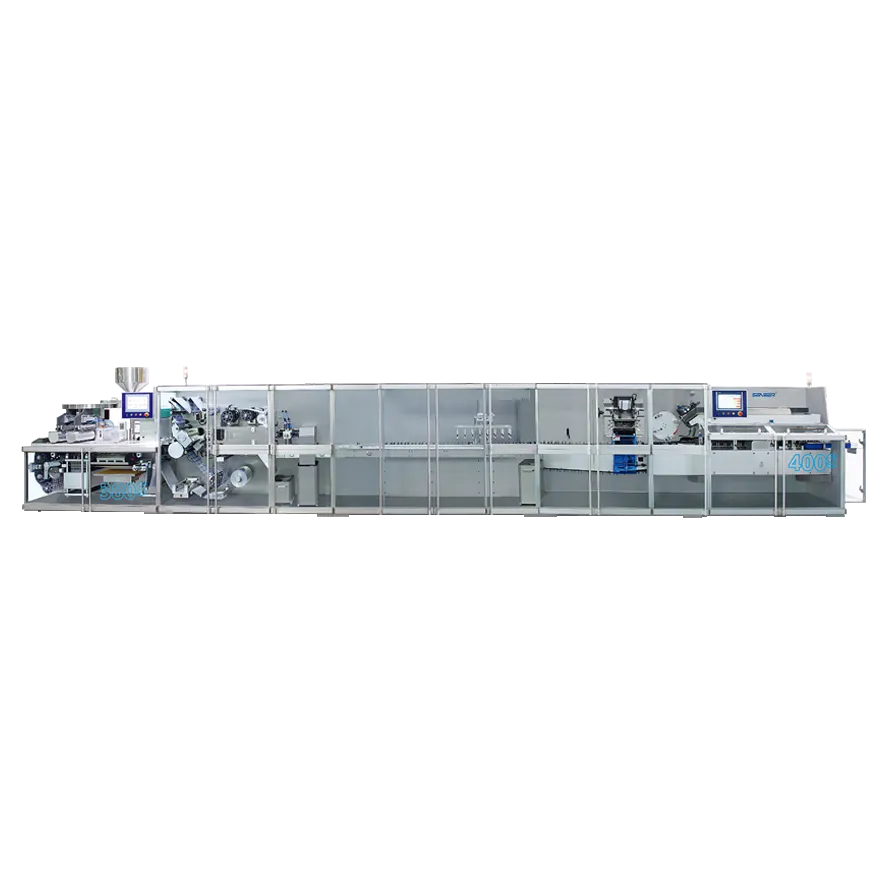

Current Product: Pharma Blister Packaging Line

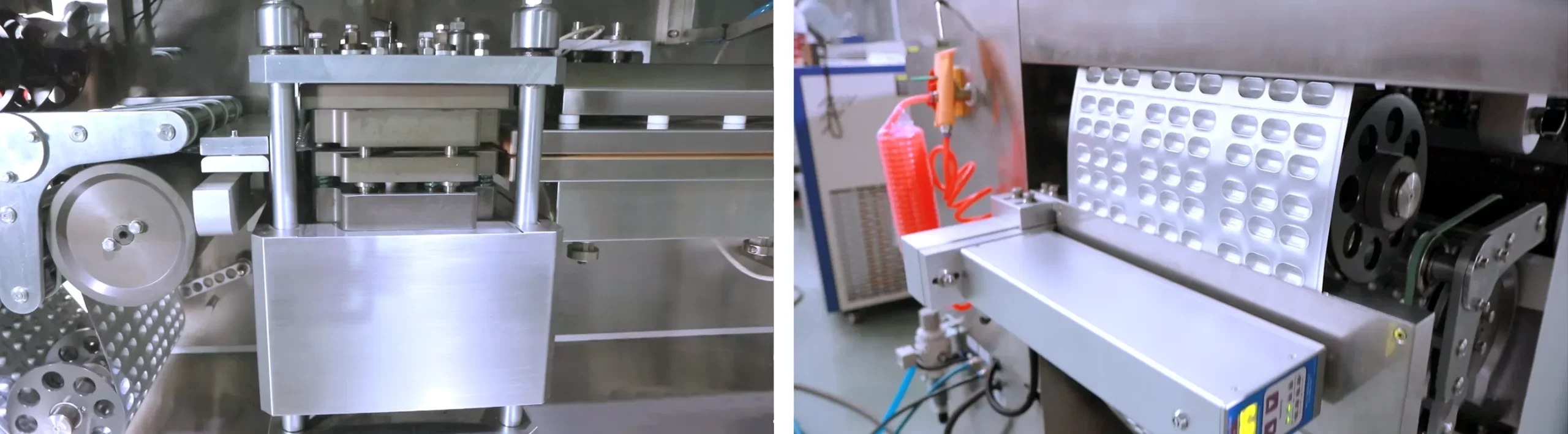

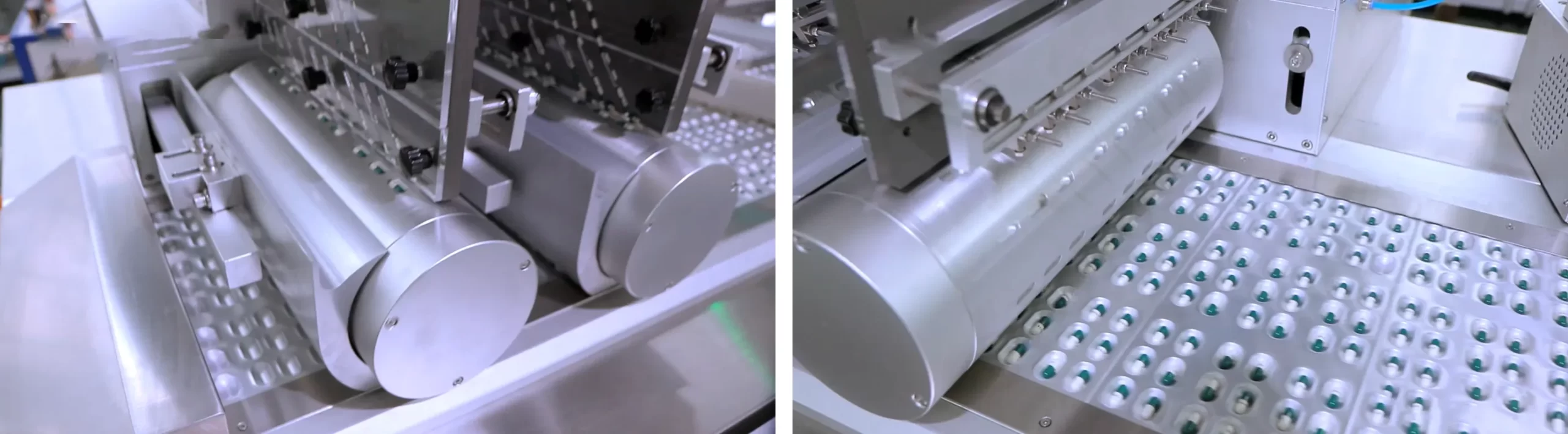

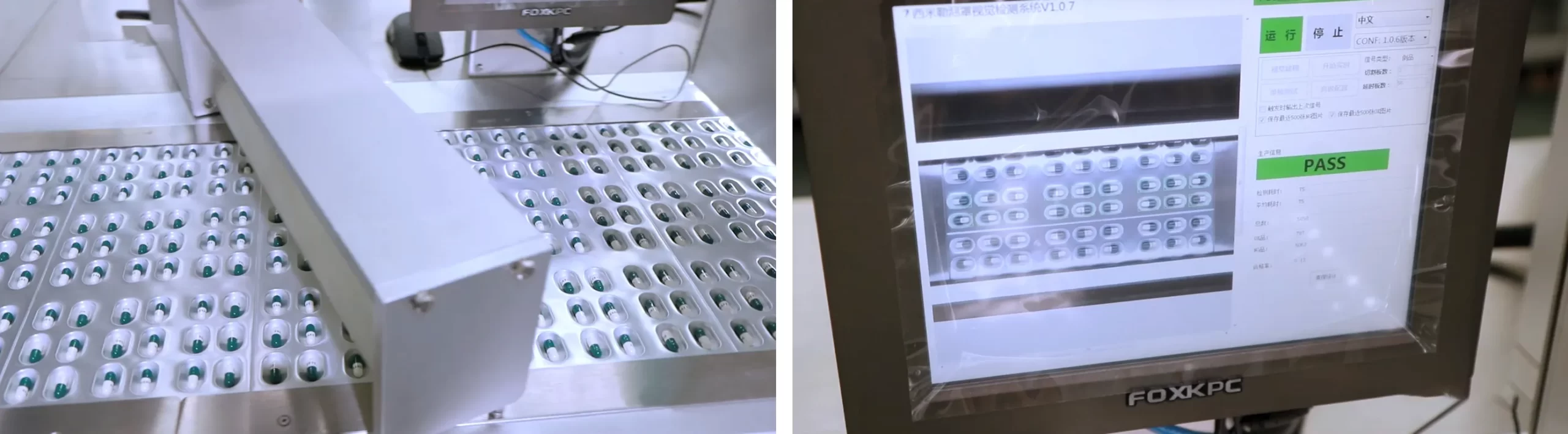

The intellectual blister packaging line is characterized by precise filling and packaging. In the transportation link, the drugs will have corresponding holes to be adjusted, which ensures the quality of product packaging. According to the production scale, sterile level requirements, and product characteristics of customers, the line can be fully customized, including sterile mold replacement, filling precision adjustment, and packaging form optimization. It has been exported to regions with strict medical standards, such as the United States, the European Union, Japan, and Australia, and has won wide recognition from customers in the medical industry. If you have relevant needs, please contact us promptly.