Home » Liquid Capsule Filling Machine For Dual Chamber Capsule

Liquid Capsule Filling Machine For Dual Chamber Capsule

Liqui capsule flling machine is specially designed for dual chamber capsules, which can automatically fill and seal multi-material capsules. The breakthrough technology from Senieer upgrades the single drug process in the pharmaceutical industry, achieving the effect of double drug dissolution.

Introduction of Liquid Capsule Filling Machine For Dual Chamber Capsule

Liquid capsule filling machine for dual chamber capsule, also fully know automatic hard gelatin capsule liquid filling and sealing production line. This equipment can complete the filling of hard capsules (solution, suspension, microemulsion, or hot melt) and the sealing of the joint of the capsule cap.

The material in the capsule is always in a sealed state during packaging, transportation, and use, thereby improving stability and safety. While ensuring the quality, it provides a more efficient and stable hard capsule filling liquid and sealing solution for pharmaceutical companies, health care product factories, and other industries. It is a boon for the development of preparations (highly active drugs, poorly soluble drugs).

Different Types of Liquid Capsule Filling Machines

In order to meet different production needs, Senieer provides a variety of models.

Choose the Senieer Liquid Capsule Filling Machine

Automatic Hard Capsule Liquid Filling and sealing machine linkage line widely used in the pharmaceutical, food, and nutraceutical industry, which can meet the requirement that two types of materials will not react and can be filled into the capsule together, to sure timely treatment and interaction between drugs.

The general working principle of each station:

1 and 2: Capsule separation station. 3: Transition station. 4: Inspection station. 5: Filling station. 6 and 7: Mixing and filling station. 8: Waste rejection station. 9: Transition station. 10: Locking station. 11. Pushing out the collection station.

Guidelines For Liquid Capsule Filling Machine

This guide will give you an in-depth understanding of the Automatic Hard Capsule Liquid Filling and Sealing Machine linkage line, dual chamber capsules, working principles, advantages, and various industry applications.

What Is A Dual Chamber Capsule ?

A dual-chamber capsule is an innovative delivery system that holds two different active ingredients in separate compartments. This technology allows for the synergistic combination of ingredients that might otherwise be less effective if combined or mixed prematurely.

There are some introduce about originate dual chamber capsule.

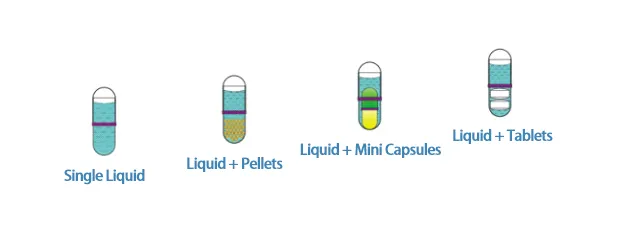

To solve the problem that different active ingredients that interact with each other in conventional capsules cannot be included in the same capsule, doTERRA Essential Oils Europe launched dual chamber capsule in 2019, or called capsule-in-capsule. with the progress of science and technology, dual chamber capsule has more forms, such pellets-in-capsule, tablets-in-capsule, etc.

The Composition Liquid Capsule Filling Machine For Dual Chamber Capsule

12-station turntable

The 12-station turntable adopts integral processing to achieve a compact structure, no splicing gap, good sealing, easy disassembly, and easy maintenance.

Liquid filling mechanism

Liquid filling and filling mechanism adopt a high-precision ceramic pump, and the measurement accuracy is ±2%.

Turntable connection mechanism

The turntable connecting mechanism adopts a modular design, which is easy to clean and replace molds.

High-precision optional fiber detection system

Optical fiber sensing has high-speed transmission capability, high sensitivity, no interference from magnetic field noise, and long service life.

Capsule introduction mechanism

The capsule introduction mechanism has automatic capsule guidance, optical fiber detection inside the capsule storage plate, and high and low positions of the capsule to control the speed synchronization function of the main machine and auxiliary machine in real time.

Sealing glue table device

The lifting and sealing rubber table adopts the servo motor control system, and the sealed glue storage can effectively prevent the glue from evaporating in the air.

Application of SCL In Different Industries

Multi-chamber capsule machines can encapsulate different ingredients in separate chambers of the same capsule to achieve precise release and combined application. Here are its applications in major industries:

- Pharmaceutical industry

Used to prepare compound preparations by placing drug ingredients with different pharmacological effects in separate chambers to avoid interactions. Meanwhile, according to the drug release requirements, it enables the precise release of each ingredient to improve efficacy and safety.

- Healthcare product industry

Encapsulates multiple nutritional or functional ingredients in one capsule to achieve composite functions and meet one-stop health needs. It can also isolate volatile and oxidizable ingredients to ensure their stability and biological activity.

- Food industry

Applied in the production of functional foods and nutritional supplements to realize the diversified and functional combination of ingredients and nutrients. It is also used to produce convenient products such as capsule coffee and capsule tea, as well as to create high-end foods with multiple flavors and functions.

Advantages Of SCL

- Ingredient Isolation and Protection: It can separate ingredients with conflicting physical or chemical properties into different chambers to avoid interactions. Meanwhile, it protects unstable ingredients such as oxidizable and volatile ones, maintaining their activity and stability.

- Precise Release Control: It can design the release time and site of ingredients in each chamber according to requirements, achieving timed and targeted release, improving efficacy utilization, and reducing side effects.

- Optimized Formula Combination: It supports the combination of multiple ingredients and doses in a single capsule, meeting the needs of complex formulas such as compound preparations and multi-nutrient supplements, and simplifying the administration process.

- Enhanced Product Added Value: It provides differentiated product solutions for industries, such as multi-functional health products and precision drug delivery medications, helping enterprises develop high-end and characteristic products.

- Improved Production Efficiency: The integrated encapsulation process can reduce production links for multi-dosage form combinations and lower costs. At the same time, it ensures accurate dosing, complying with industry quality standards.

How to Clean Your SCL?

Cleaning of the capsule filling machine mold and the sealing machine mold.

- After the capsules are filled, please turn off the power, raise the hopper, and remove it.

- Remove the sensor and cover plate from the material hopper, and take out the powder in the material (no pollution) and put it in the warehouse.

- Remove all machine parts that need to be disassembled and washed, such as modules, vacuum cleaners, chain plates, and drying molds, with special tools, and place them neatly and lightly on the trolley, and put the screws together in the container.

- When replacing the variety, remove the bag fork, empty bag hopper, and vacuum tube with special tools and put them on the trolley.

- Push the removed mold to the container washing room, wash the machine parts with a mercerized towel and hot water to remove the attached dust and residue, and finally scrub it with purified water.

- The sensor must be dismantled and handled with care, wiped clean with a mercerized towel dipped in 75% ethanol, and cannot be washed with water.

- Dry all the cleaned parts with a mercerized towel, and place them neatly on the trolley frame. After counting the quantity, push the trolley to the container drying room to dry the items.

- Return the dried capsule filling machine mold to the die room for storage and put it in a special mold box.

Cleaning of the capsule filling machine body and accessories.

- Use a special vacuum cleaner for filling to clean the accumulated powder on the plane of the turntable. Use a vacuum cleaner to clean the dust inside the machine, remove the chain plate, drying module, upper and lower modules, and other parts on the machine, and then soak them in ethanol for about 15 minutes. After a few minutes, wipe clean. Finally, dry with a clean, dry silky towel.

- Use a vacuum cleaner to clean the dust outside the capsule machine, wipe it with a clean, wet mercerized towel until there is no product residue, and finally dry it with a clean and dry mercerized towel.

- Move the vacuum cleaner to the container washing room for cleaning.

- Dry all the cleaned parts with a mercerized towel, and put them in the container drying room to dry.

Field clearance inspection

- Visually check that there are no water stains and residues on all parts of the equipment; wipe with a clean towel, and ensure there are no traces of uncleanness and no residual liquid.

- After the clearing is over, the operator shall fill in the clearing record according to the regulations.

Why Choose Senieer?

The automatic hard capsule liquid filling machine and sealing linkage line equipment are independently developed and designed by Senieer. It is based on our own hard capsule liquid filling machine and sealing linkage line technology for many years, and has been greatly improved in terms of performance and output. It is a cost-effective hard capsule filling, liquid, and sealing linkage line equipment. We have cooperated with South America many times, such as Argentina, Bolivia, Brazil, Chile, etc. Welcome to consult.

Choose Your Interested Production Line

Bottle Filling Line

Granulation Line

Blister Packaging Line

Powder Filling Line