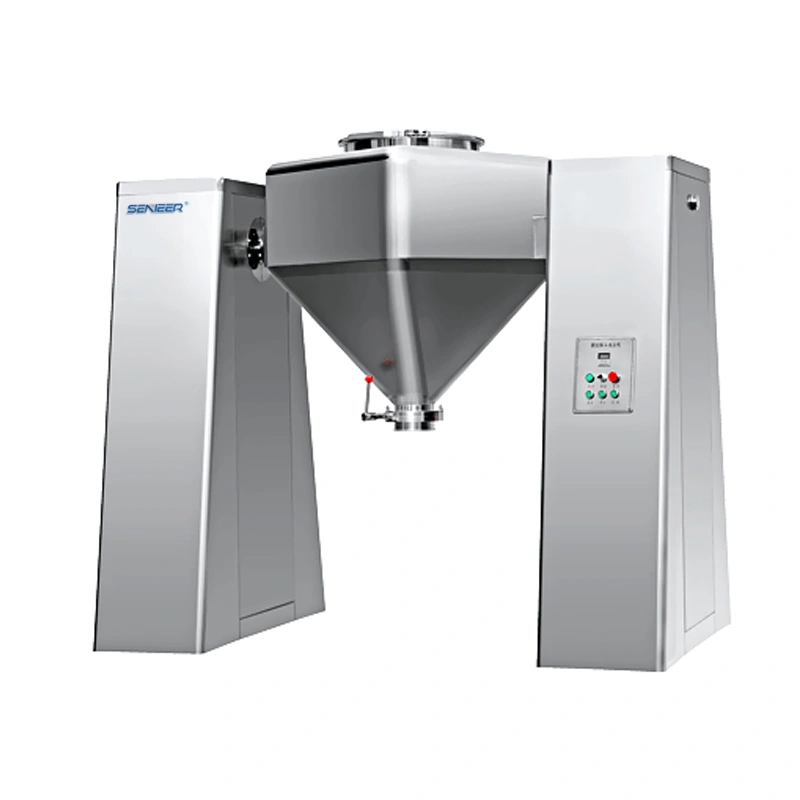

Current Product: BVC 800 Pharmaceutical Bin Blender

The Pharmaceutical Bin Blender is an industrial powder mixing machine designed for pre-blending and final mixing of a wide range of products across the pharmaceutical industries, ensuring high powder mixing uniformity. Adopts a modular design, allowing users to choose the appropriate mixing bin type and configuration based on their specific needs. Senieer always treats consultation with a customer-first attitude and has achieved satisfactory cooperation with the USA, Canada, Australia, the UK, France, Spain, Egypt, etc.