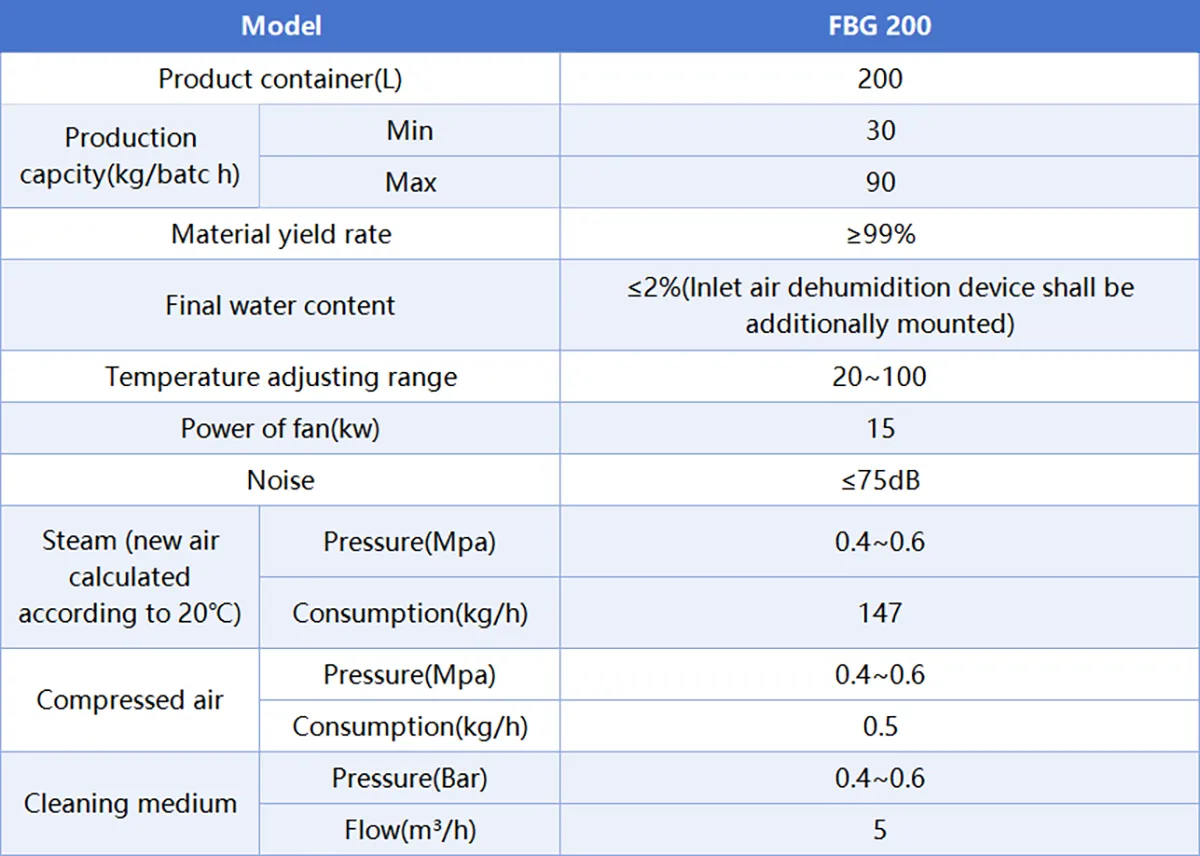

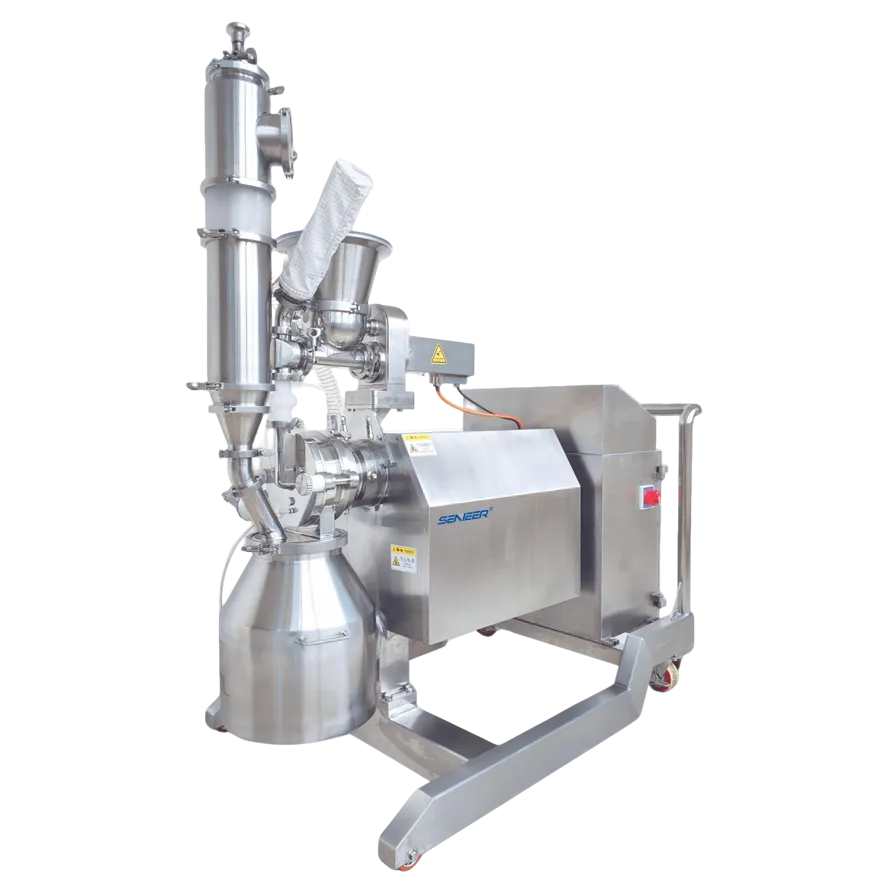

Current Product: FBG 200 Fluid Bed Granulator

FBG 200 fluid bed granulator utilizes top spray fluid bed granulation technology, which uniformly coats particles with a thin film to enhance their flowability and compressibility. Equipped with an advanced online monitoring system, it continuously tracks particle size and uniformity, ensuring consistent quality. The high-efficiency heat exchange system further reduces production time and boosts efficiency. Available in the Philippines, the United States, Spain, Egypt, and other regions, our products are ready for your inquiry.