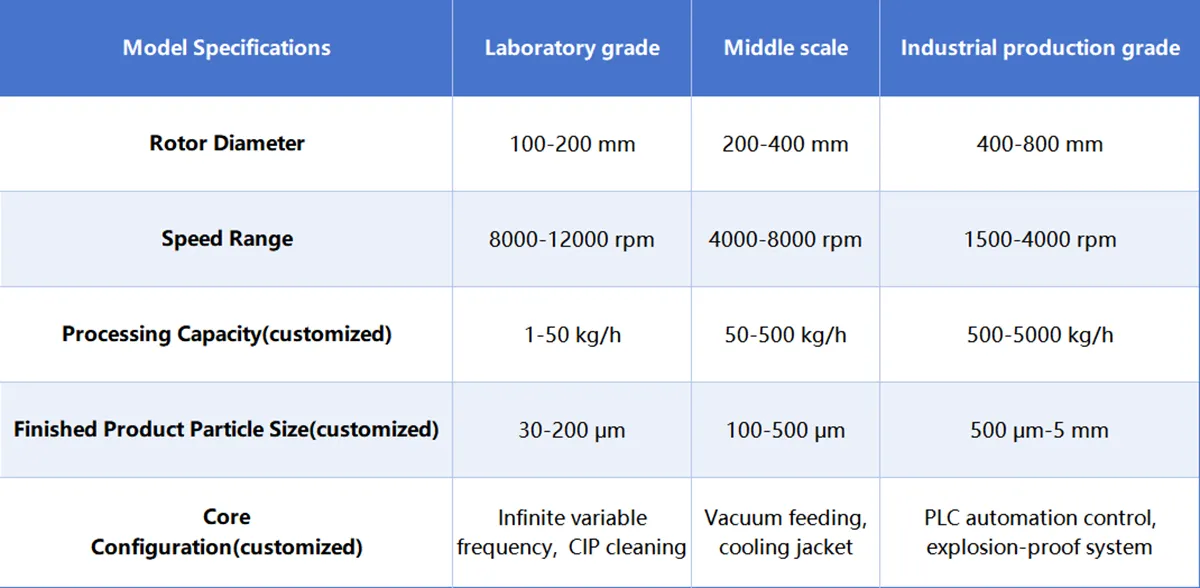

Current Product: Food Processing Hammer Mill

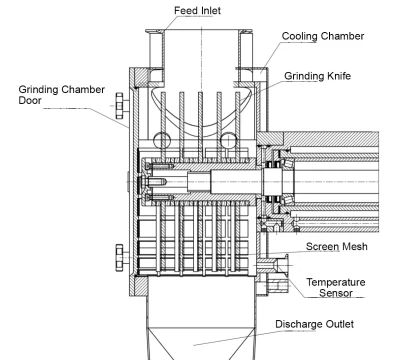

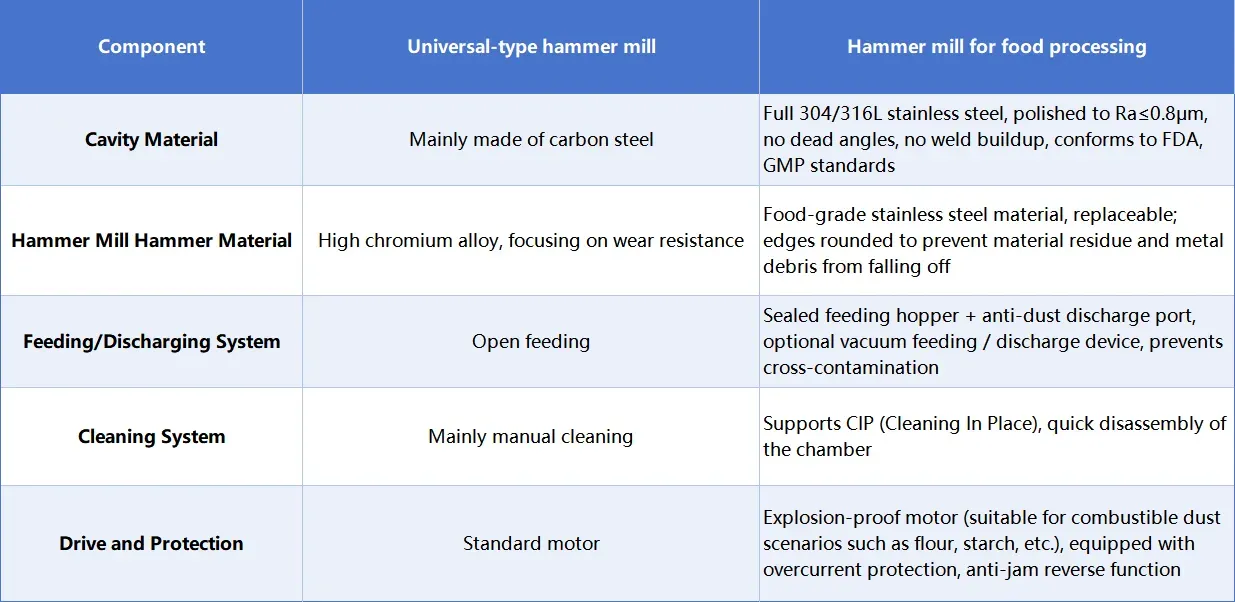

Food processing has extremely high requirements for the environment and hygiene. As a top hammer mill manufacturer, Senieer developed this hammer mill specially for the food industry. It is durable and strictly implements GMP standards. It is an ideal choice for food production and processing.

It is widely used in North America, Brazil, Argentina, Vietnam, and other agricultural countries. It has passed the harsh production environment verification in many countries in North America, South America, and Southeast Asia. With over 37 years of crushing expertise, Senieer delivers global technical support to fulfill customized needs, conduct sample testing, and provide turnkey solutions.

Are you interested in this equipment? Welcome to contact us at any time, we provide professional technical support.