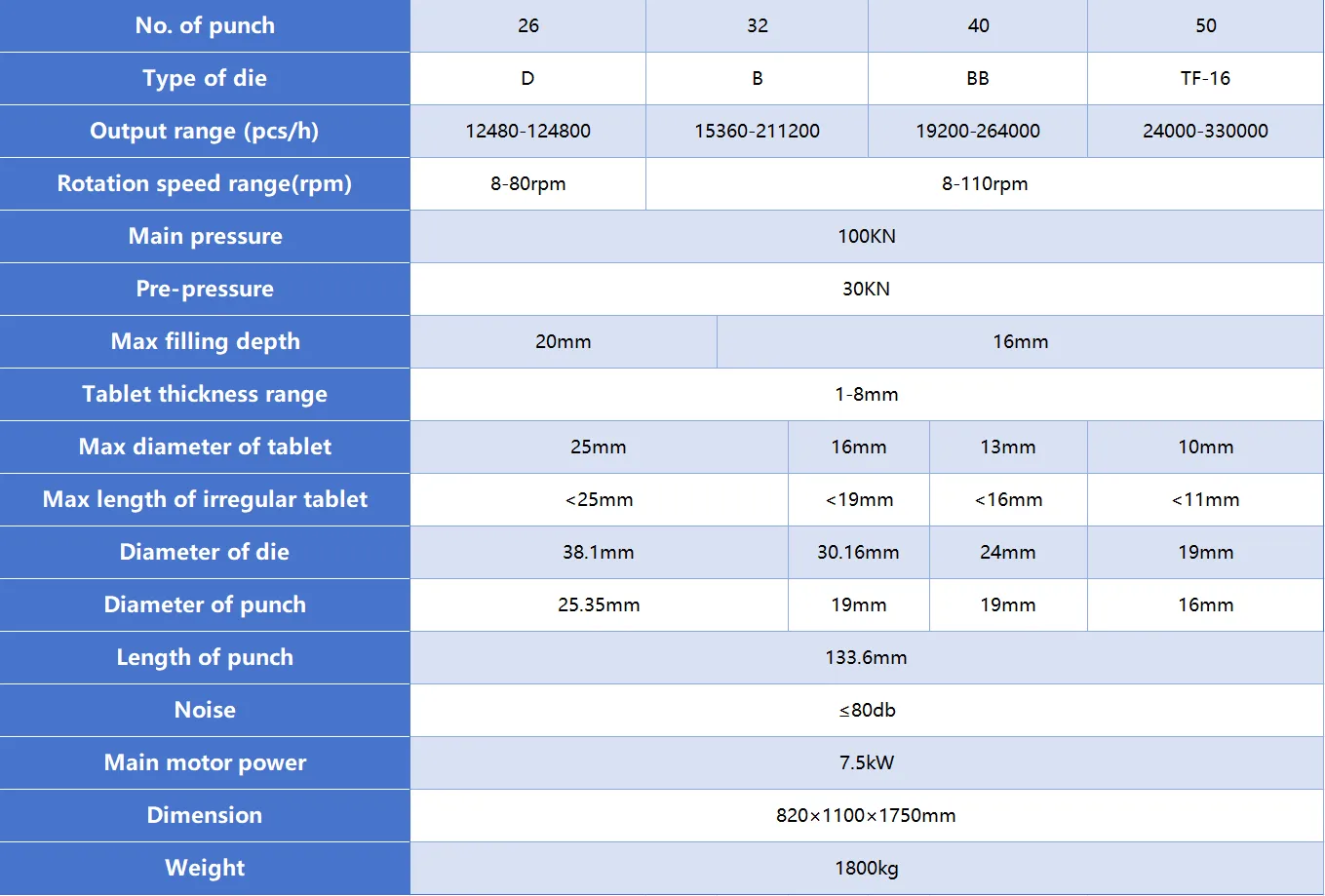

Current Product: Pharmaceutical Tablet Making Machine

The rotary tablet press machine briefly contains the following three steps: powder filling, compression/press molding and tablet discharge. The rotary turret designs allow for continuous tablet press production, which increases the production scale and efficiency. We exported products to global countries such as Peru, US, Middle East, South Africa, Indonesia, etc. We offer comprehensive services for global customers.