Current Product: Continuous Fluid Bed Dryer

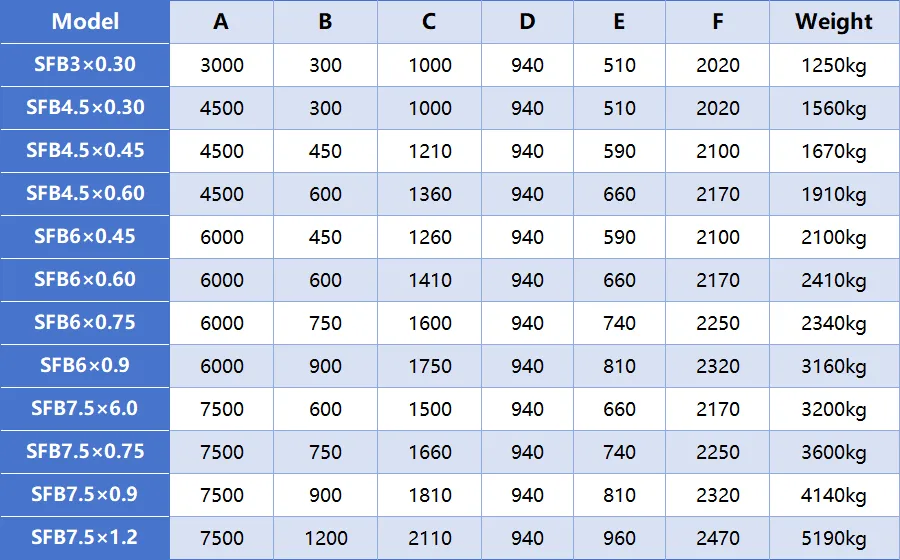

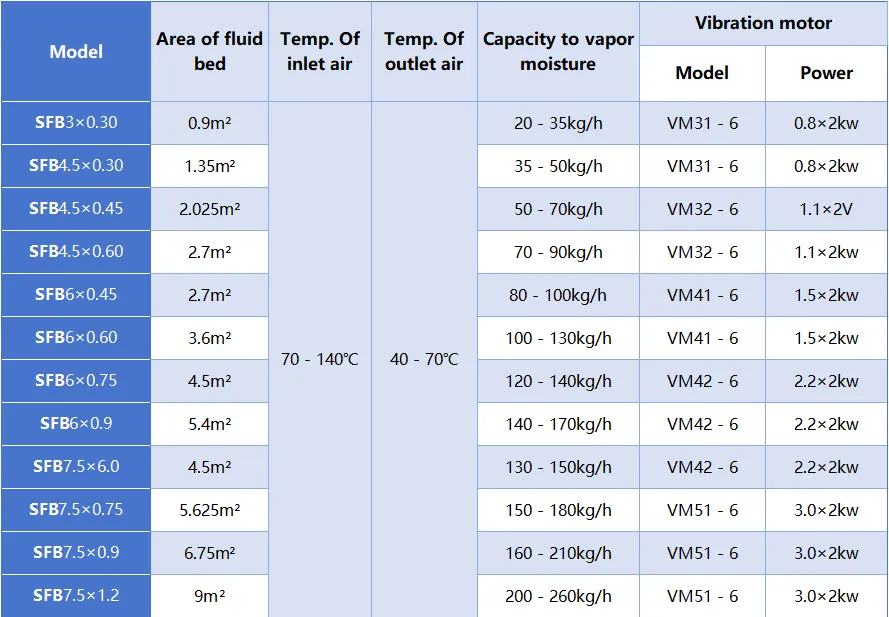

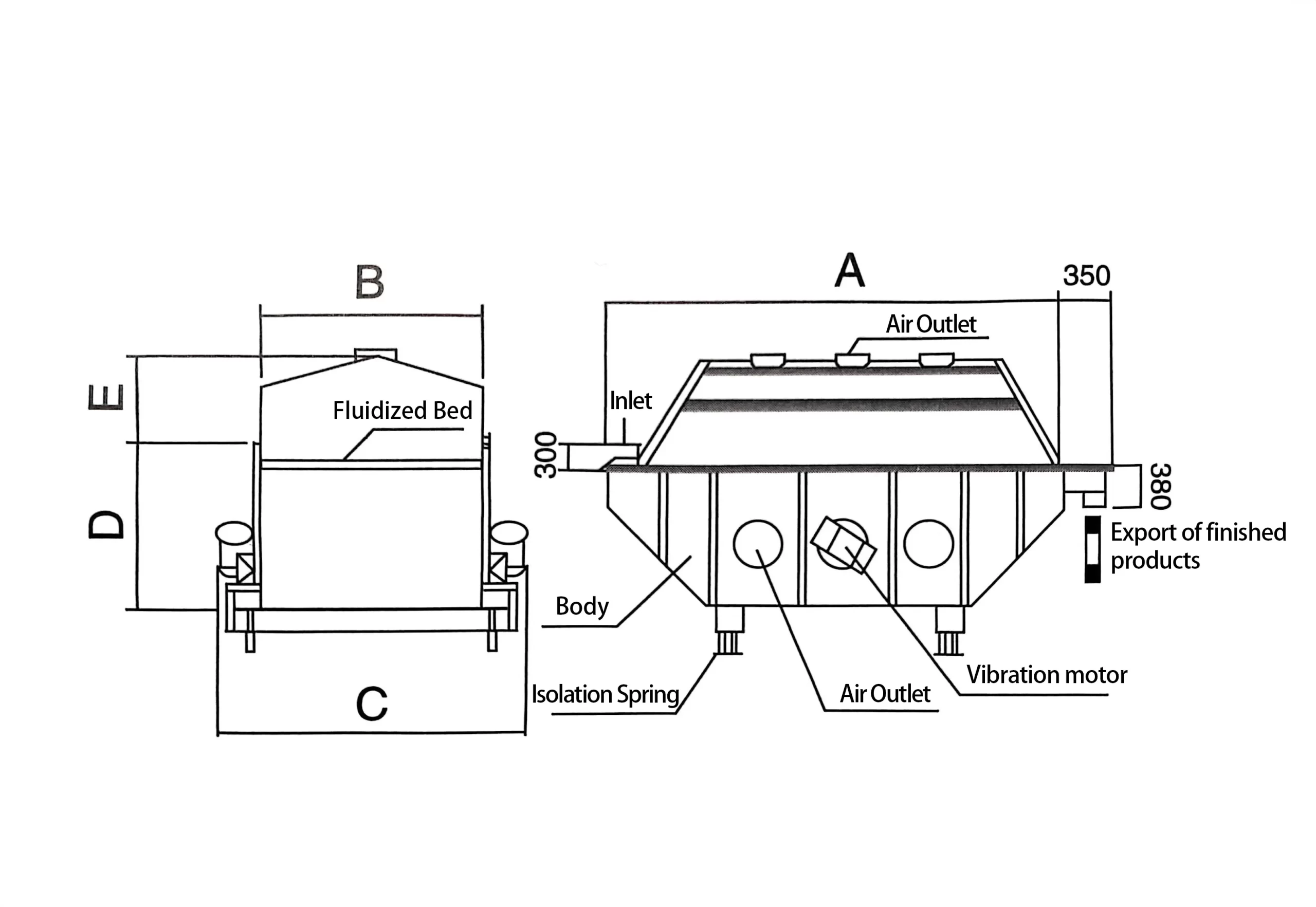

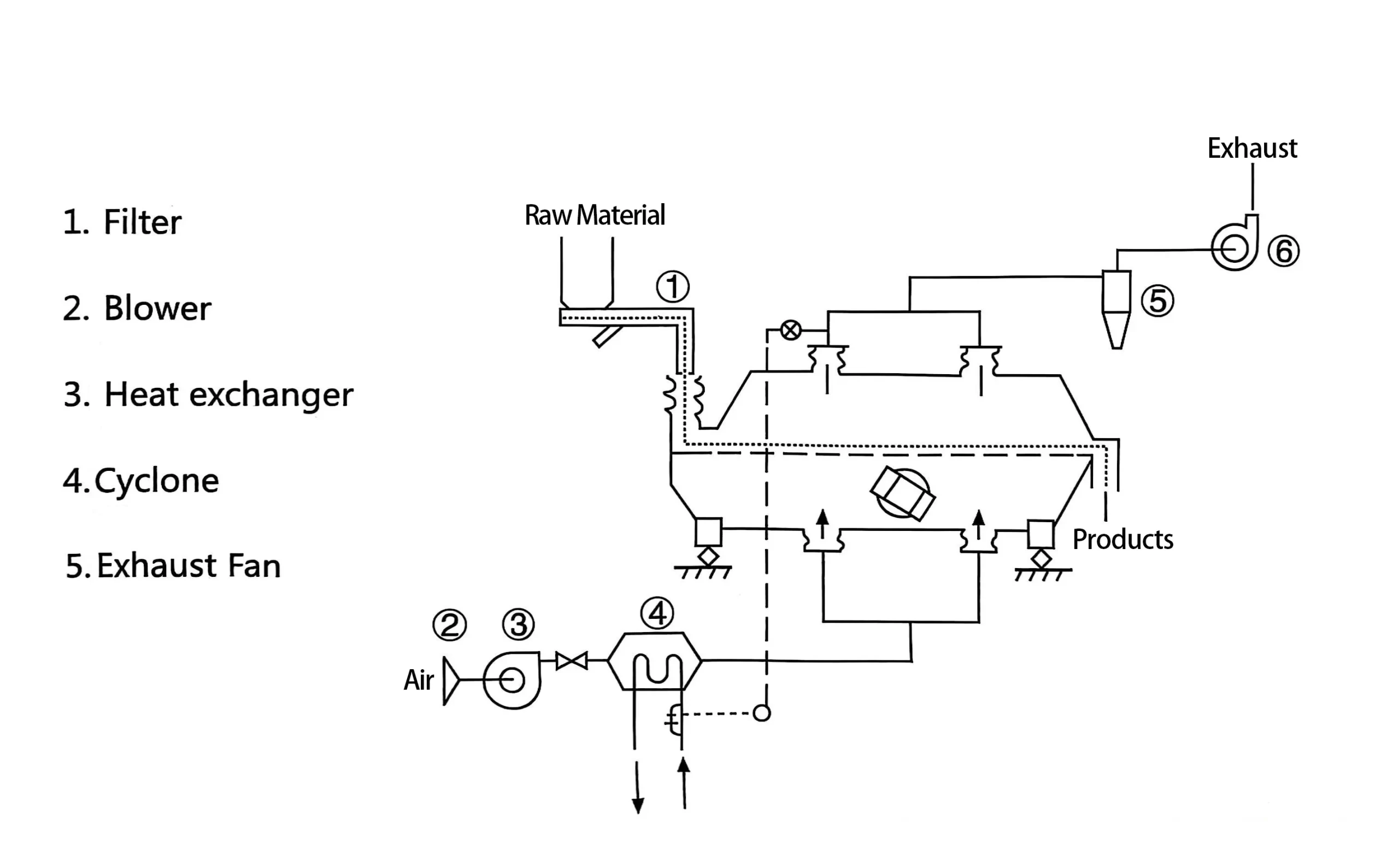

Continuous fluid bed dryer adopts vibratory way to move materials forward, so it is also named vibrating fluid bed dryer. The materials are fed constantly and dry materials are discharged continuously. It is often equipped with screw conveyor or vacuum feeder for continuous and large scale of materials feeding and production. Senieer offers customized service. One-stop solutions are our feature and strength. Welcome to contact us.