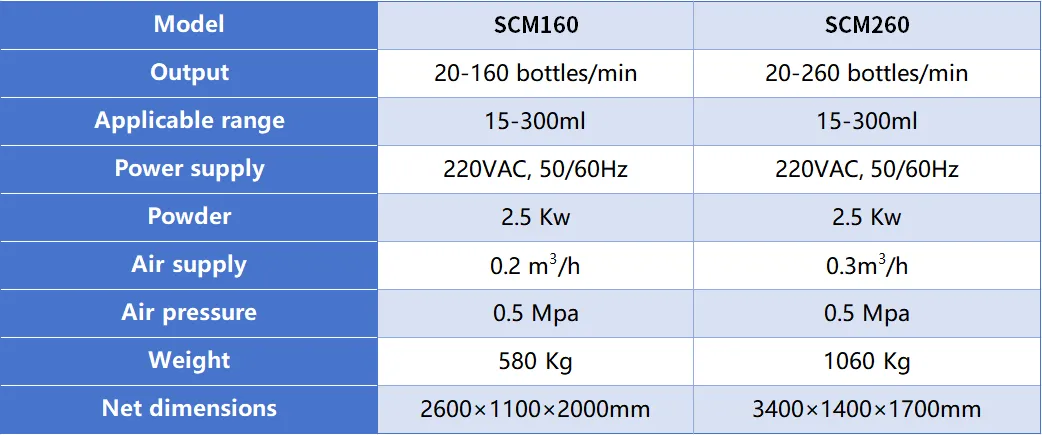

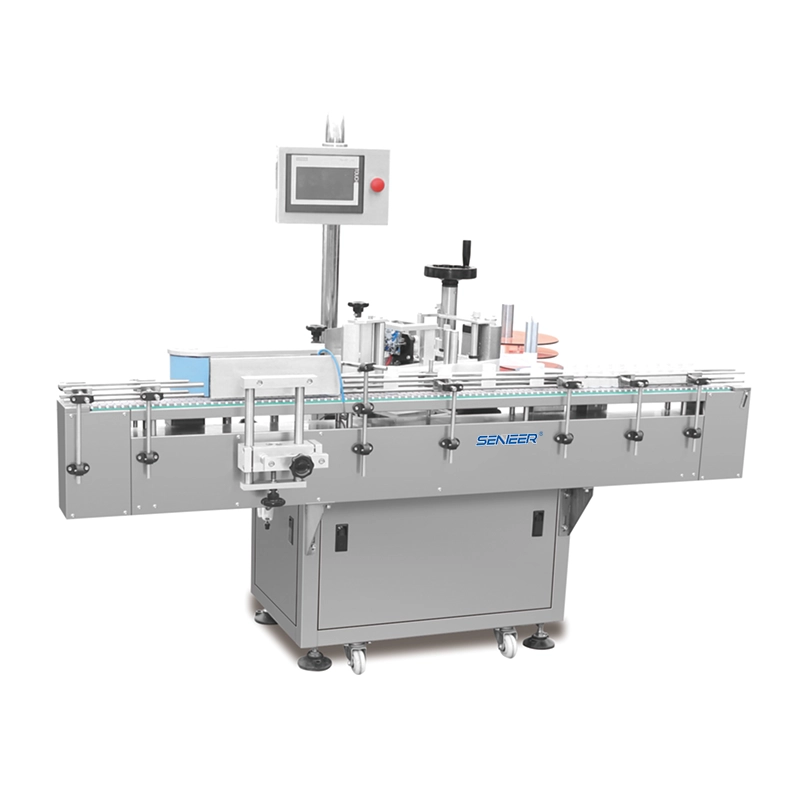

Current Product: Automatic Capping Machine

Our automatic capping machine has a high-performance, featuring automatic rejection when the caps are not secured tightly or inclined. It has a high level of automation, operate stably and has a low noise. Conveniently operate and maintenance, strong adaptability. The large volume of cap storage hoppers, reducing adding caps continuously, reducing the labor intensity of operators. It can also be used in conjunction with bottle unscrambler, tablet counting machine, cap sealing and sticker labeling machine to form a complete capping line.