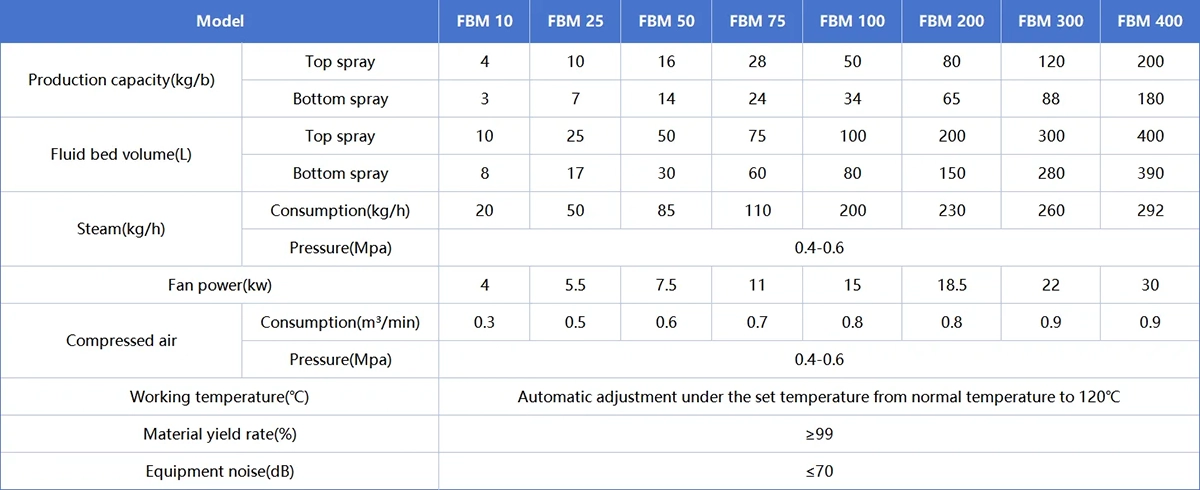

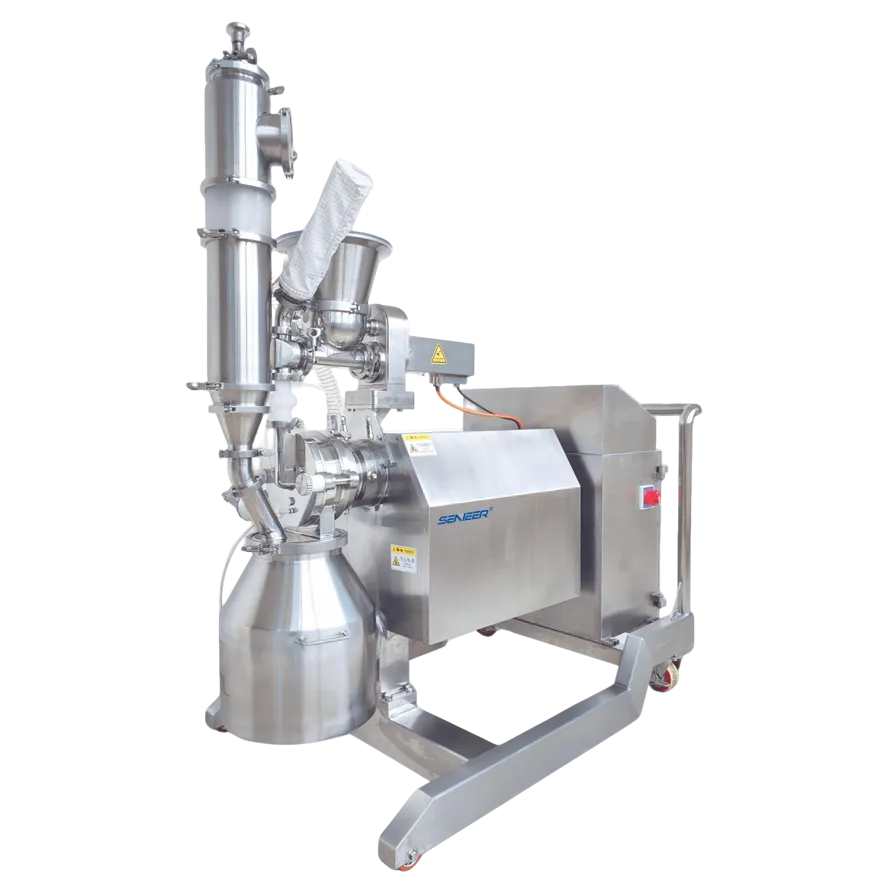

Current Product: Pharmacy Fluid Bed Processor

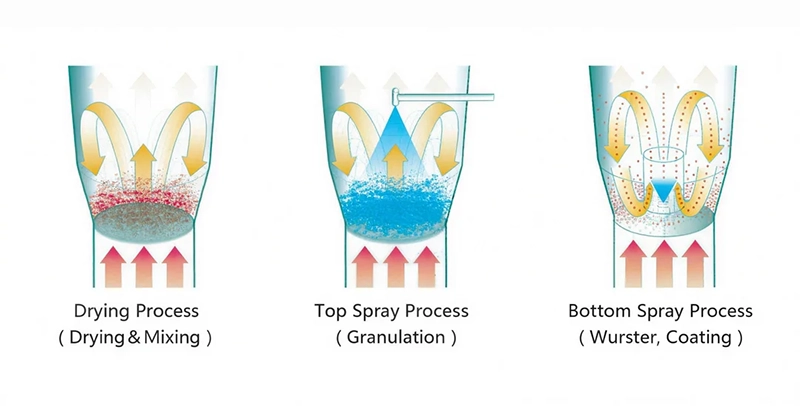

The fluidized bed processor is a versatile and high-performance device widely used in various processing operations such as drying, granulation, and coating of powders and particles. It is extensively applied in industries including pharmaceuticals, food, nutritional supplements, and chemicals, providing efficient, precise, and scalable solutions. This system ensures stable product quality, reduces processing time, and complies with the highest hygiene and safety standards, making it an ideal choice for GMP-compliant environments.