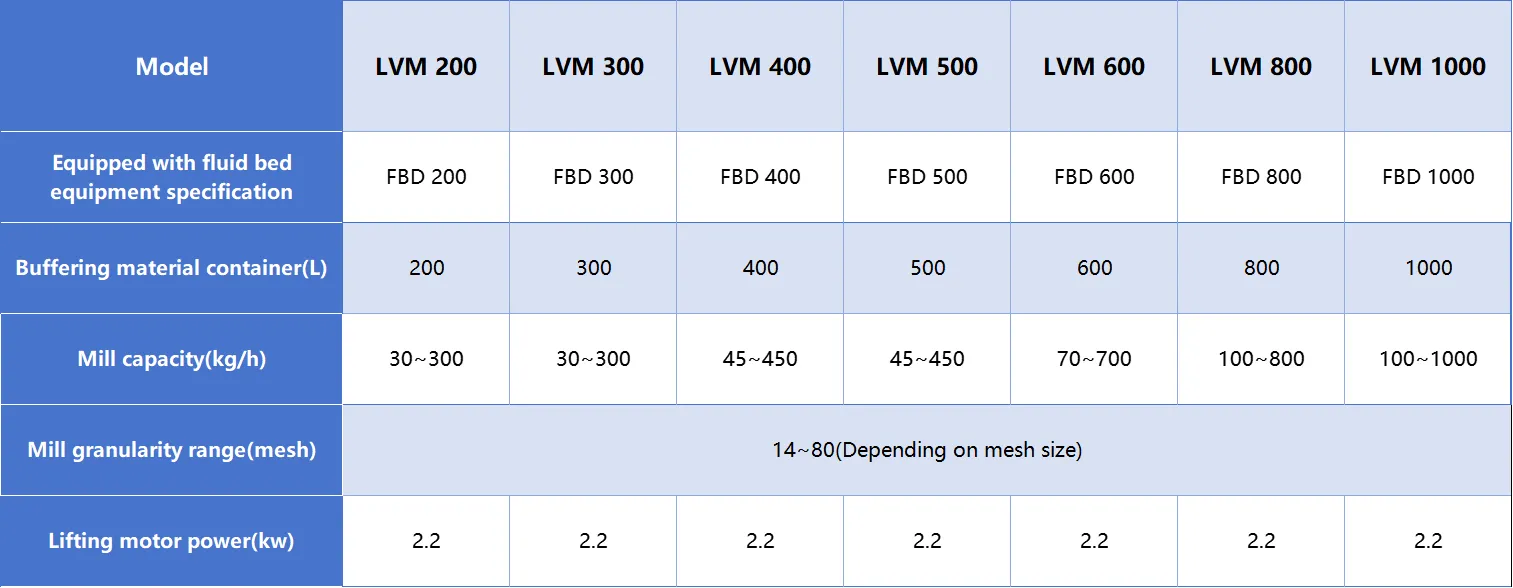

Current Product: LVM Vacuum Conveyor With Cone Mill

As the most critical machine in material transportation, the LVM vacuum conveyor with cone mill also meets the functions of vacuum transportation, lifting, and whole grain, optimizing the production process and improving efficiency. Its robust construction and high-quality materials ensure durability and long service life, even in demanding industrial environments.

Do you need us to adjust the details of a specific part according to your actual application scenarios? Come and contact us.