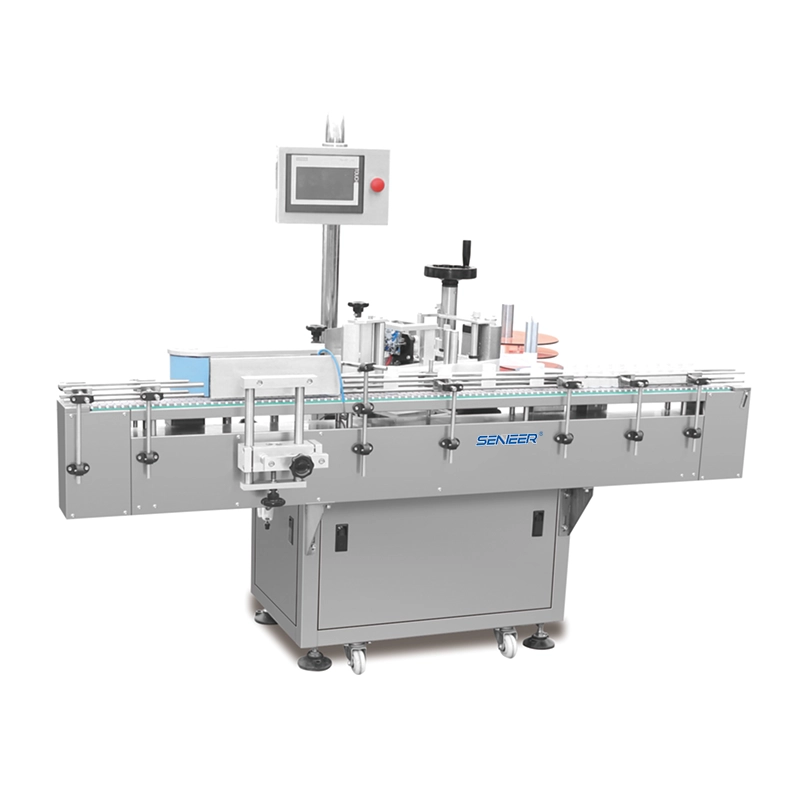

Current Product: SSC Screw Capping Machine

SSC Screw Capping Machine is a high automatic capping machine designed by Senieer professional team and has many unique characteristics. All processes including cap sorting, feeding and capping, are operated automatically. Touch screen panel makes operation intuitive and convenient. The bottle holder and capping head rotate synchronously, ensuring no slippage during the bottle rotation. This machine adopts a turntable structure. Bottles are continuously fed into the machine through the turntable. The capping head automatically grabs the caps and completes the capping process. Small footprint and convenient maintenance. The production line can be made up with the front and back equipment.