Current Product: SRC80 Pharmaceutical Roller Compactor

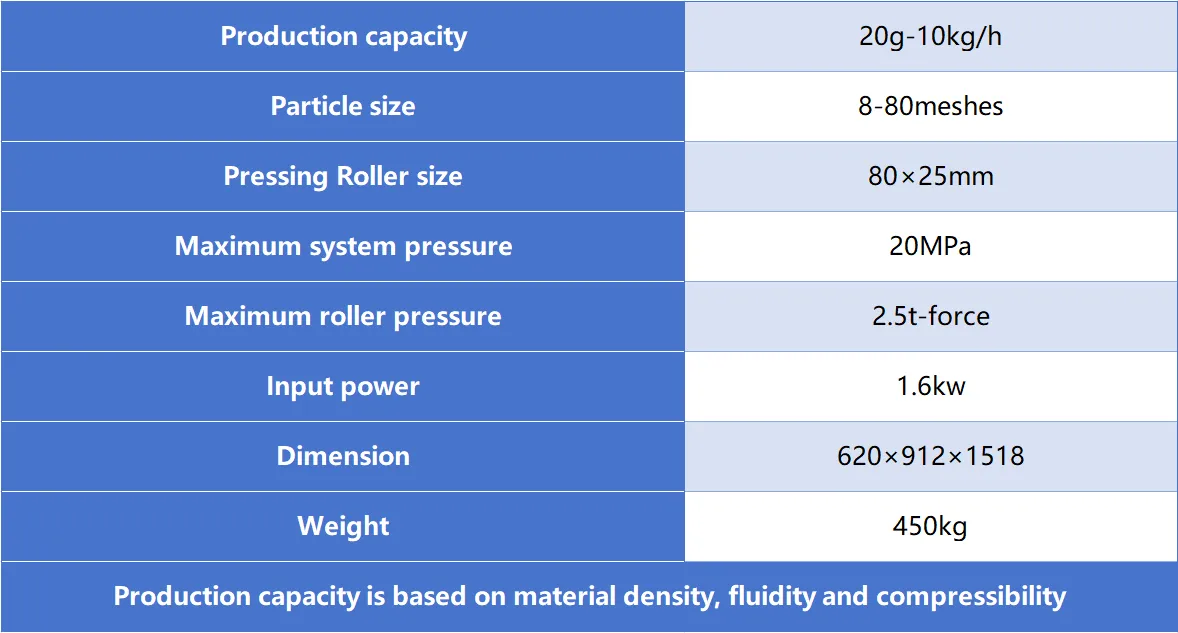

Senieer is a world famous and professional pharmaceutical equipment supplier. The oral solid dosage(OSD) is our core field and the roller compactor for pharmaceutical dry granulation is also our flagship product. There are many factors affecting the dry granulation such as humidity of material, density, flowability, compressibility, etc. Our SRC80 pharmaceutical roller compactor solves these problems and can guarantee the smooth compression and milling of materials. If you are a research institute, lab, or small and medium scale of factories, this machine is suitable for you. Want to learn about more information? Contact us immediately!