Current Product: Roller Compactor In Food

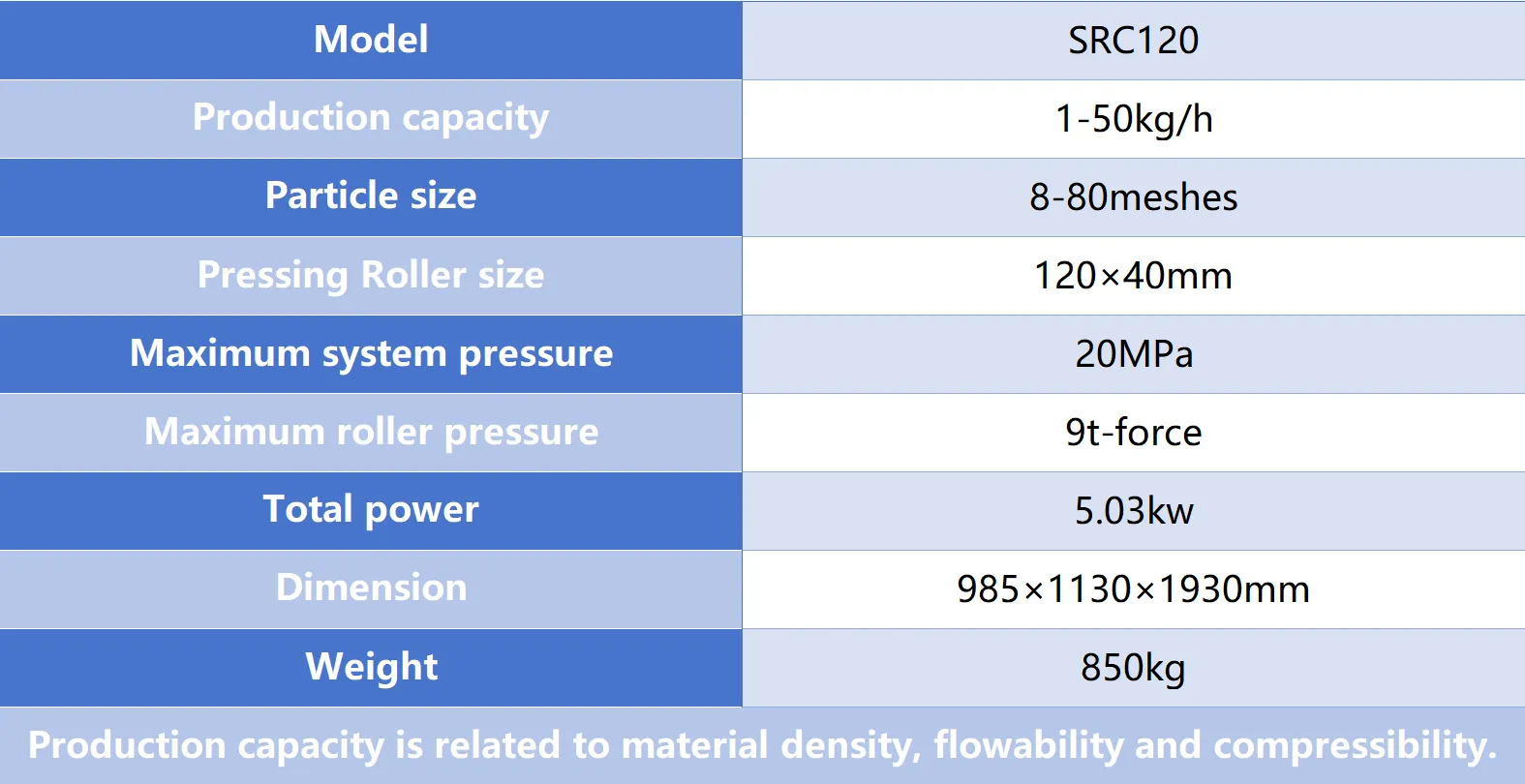

Senieer roller compactors occupy the top level in the world as the results of decades of R&D and manufacturing, no matter in performance or in appearance, it wins a lot of recognition and appreciation from clients. It is noticed that this model has a minimum feeding amount of about 100g, which is suitable for both research&development and pilot production.