Current Product: Pharmaceutical Tablet Making Machine

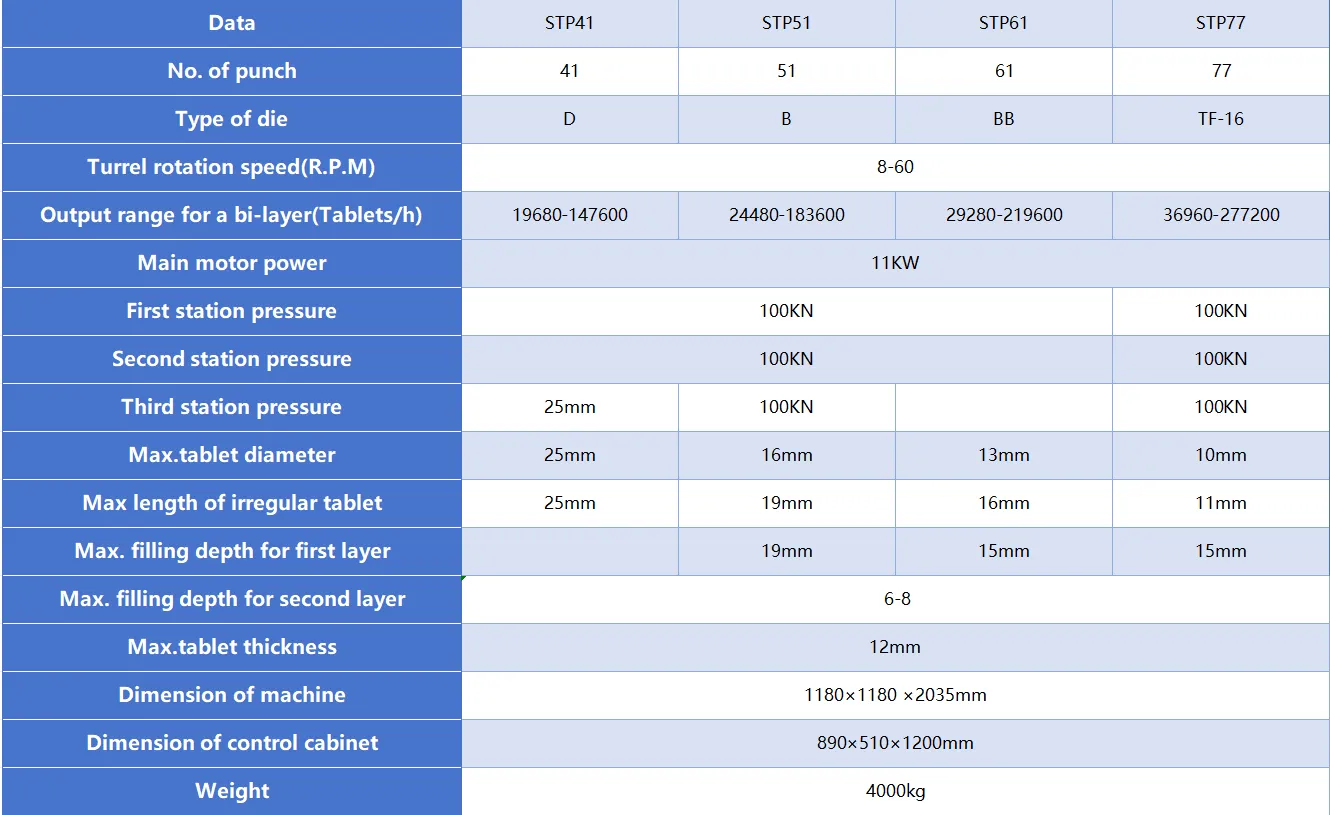

Senieer’s Pharmaceutical tablet making machine has a huge technological improvement than the previous generation of product .It uses three sets of identically sized rollers to compress the same tablet.The pressure of each set can reach 100 KN, significantly extending the tablet forming time.Senieer’s technology provides a new solution for pressing two layers tablets.