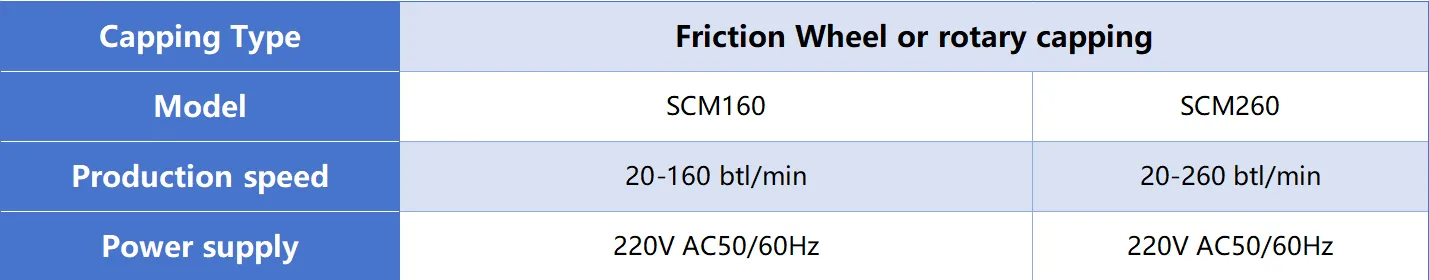

Current Product: Pharmaceutical Bottle Capping Machine

Pharmaceutical bottle capping machine consists of caps storage hopper, caps sorting or unscrambling, cap lifting and conveying, caps discharging devices, etc. It can operate stably and efficiently, has a beautiful and simple appearance as well as compact structure. The adoption of it can significantly reduces the working intensity of labors.