Advantages

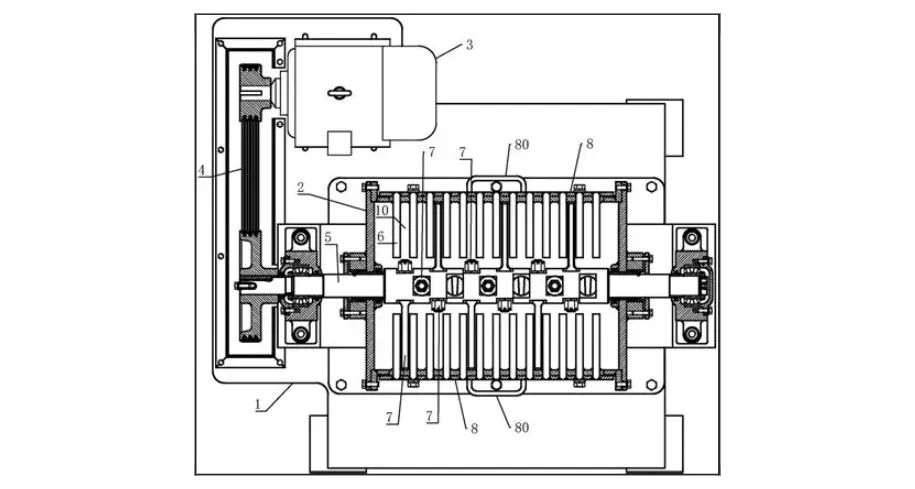

The blade of the crusher group has a cutting edge on one side and a blunt surface on the other, enabling either shearing or hammer crushing of materials.

The crusher group can be installed in reverse to quickly switch between shear crushing and hammer crushing.

By replacing the crusher blade assembly (mechanism) with different structural configurations, a wider range of crushing operations can be achieved.

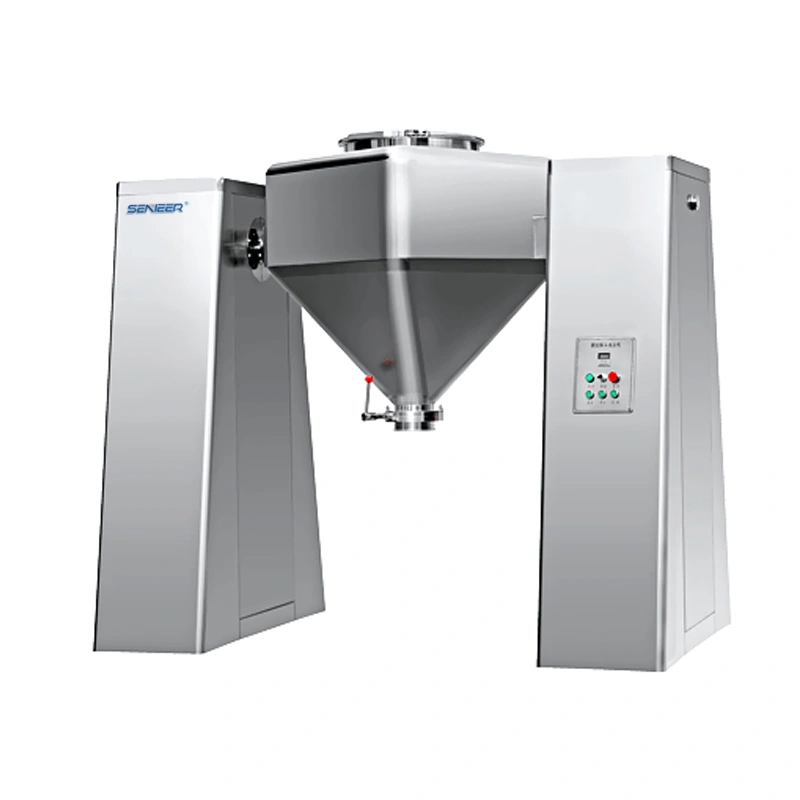

The device offers multiple optional crushing methods, making it suitable for most materials in pharmaceutical, food, and chemical industries.

During the crushing process, compressed air is used to purge the crushing blade shaft, thereby reducing the temperature of both the shaft and the crushing chamber to prevent material properties from changing due to excessive heat.

Disadvantages

It is not suitable for crushing high-hardness materials, and it is effective for soft or medium-hard materials. In the face of high hardness (such as granite, quartz stone, etc.), the hammer head wears out very quickly and the crushing efficiency decreases.

Easy to wear and has high maintenance costs. Hammer heads, grates, lining plates, etc. are all high-wear parts. Especially when crushing materials with high hardness, they wear out very quickly and need to be replaced frequently.

When it handling materials with high water or striky, it is easy to block motor so that reduce output, and even leading to downtime.