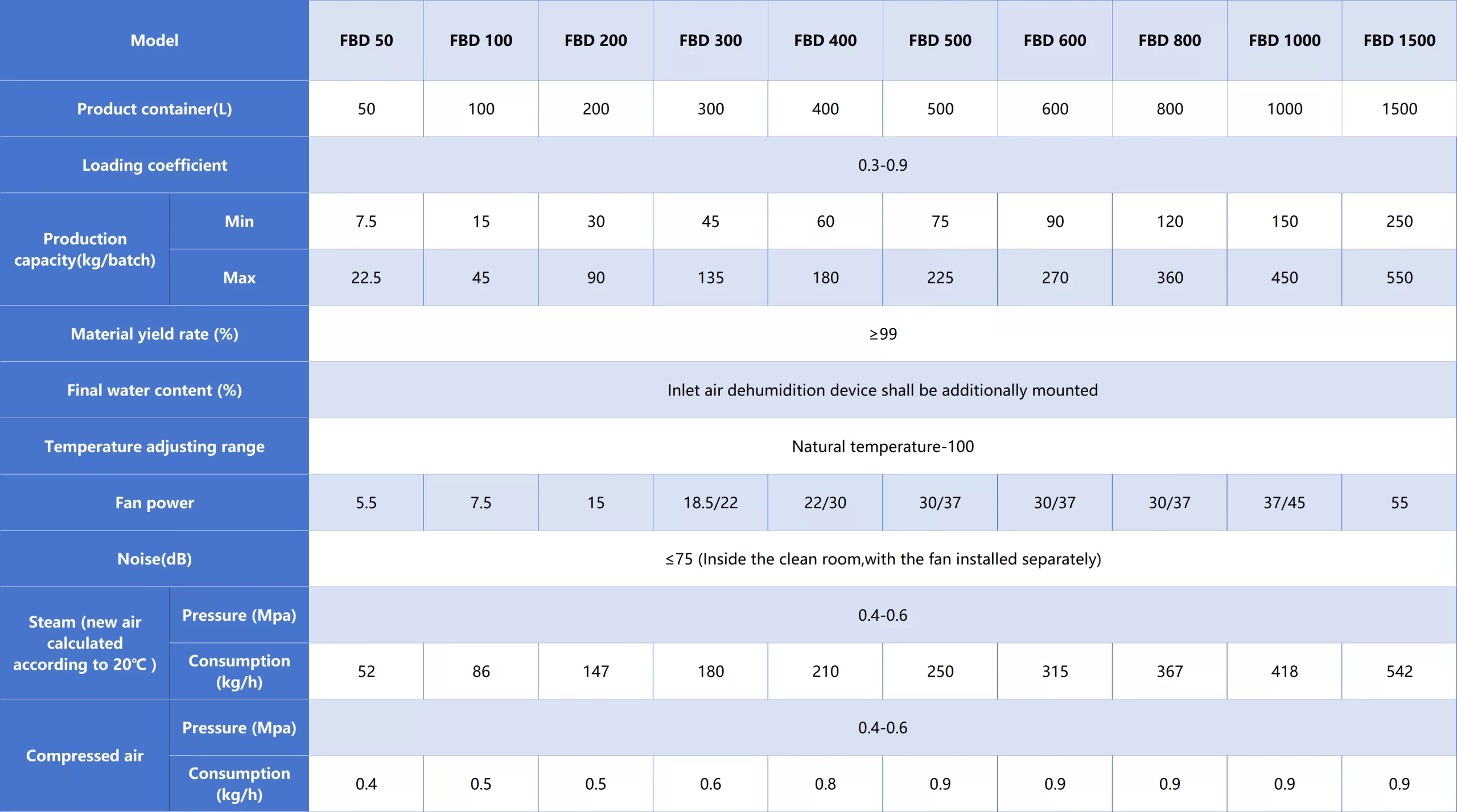

Current Product: Pharmaceutical Fluid Bed Dryer

Fluid bed dryer is a progressive drying system suitable for wet materials, such as powders and granules. As the most common drying equipment in the pharmaceutical industry, it is characterized by simple fabrication, mass production, and efficient drying. More and more pharmaceutical companies choose Senieer’s drying products. We have always focused on providing high-quality drying solutions for customers. Come and communicate with us.