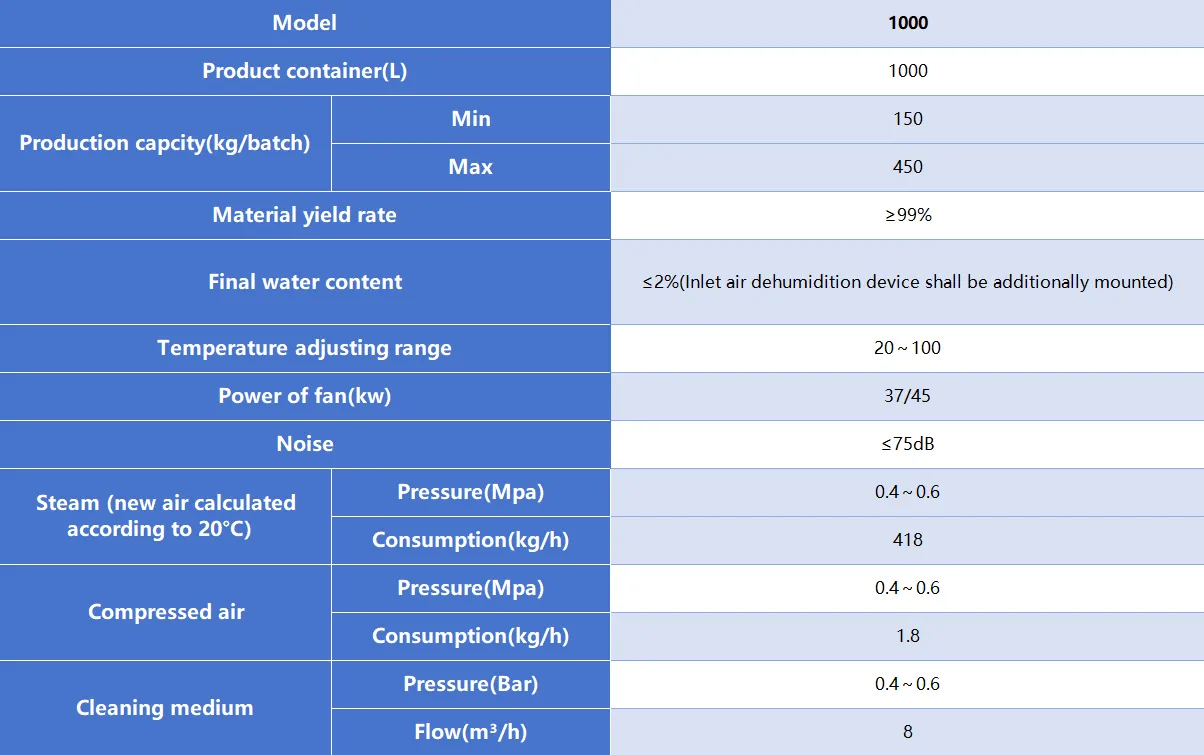

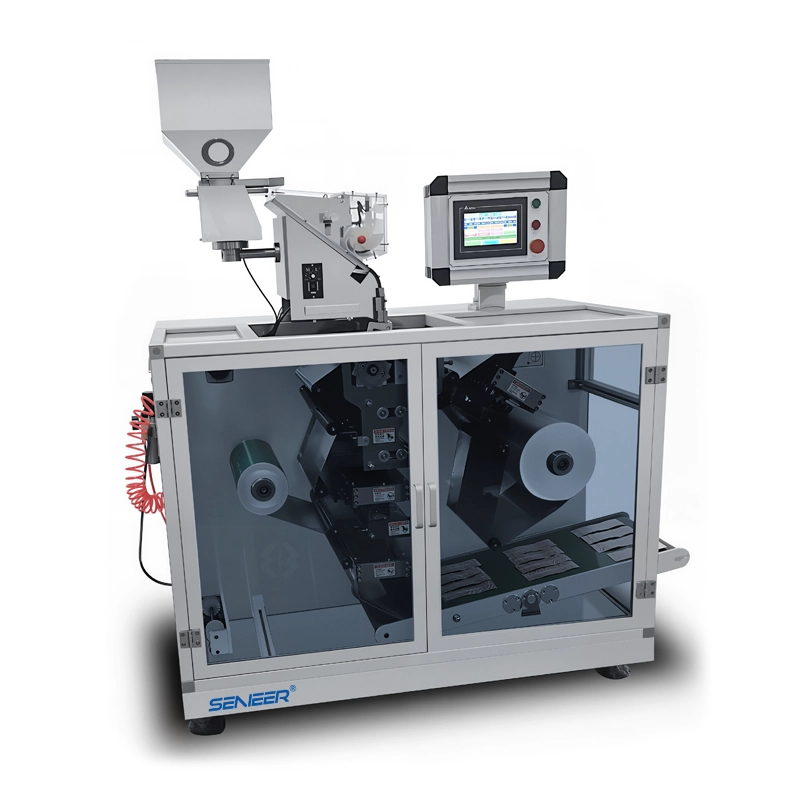

Current Product: FBG 1000 Fluid Bed Granulator

The emergence of fluidized bed has solved the problem of cumbersome and long cycle of traditional granulation equipment. The working principle determines the characteristics of one-step and high efficiency. Senieer provides a new solution that does not require separate mixing, granulation, drying and dust removal, which can reduce equipment occupancy and material transfer, and reduce pollution.FBG 1000 Fluid Bed Granulator is committed to promoting the production efficiency of large-scale granulation and is the best choice for enterprises.Are you interested? Welcome to consuit!