Home » Bottle Filling Line

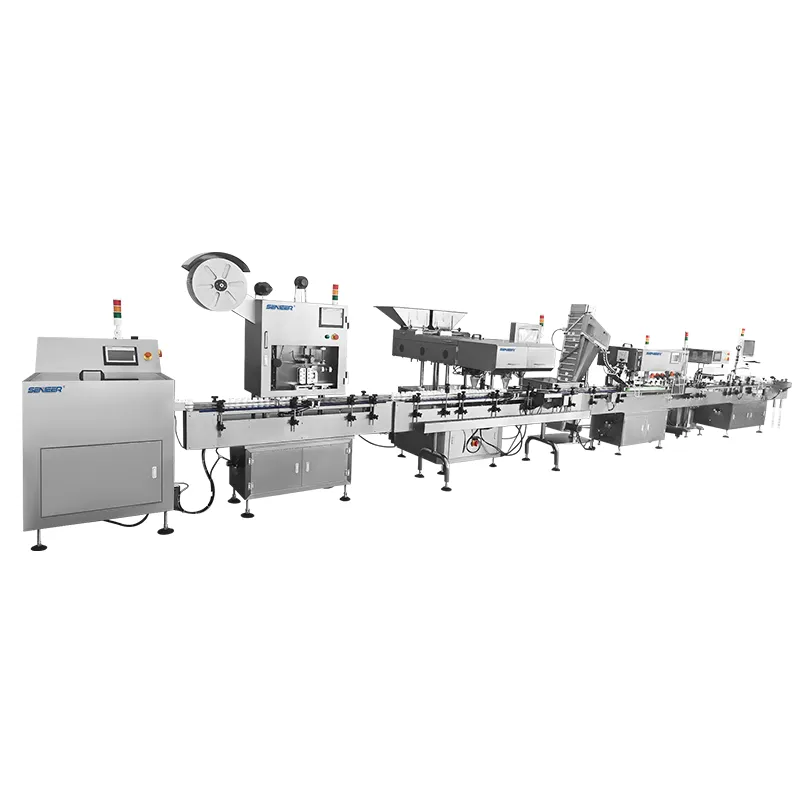

Bottle Filling Line

Precision, Efficiency, Customization.

Senieer®- Your exclusive bottle filling line solution. Suitable for accurate counting of tablets, capsules, soft gels, pills, gummy and other solids.

Introduction Of Bottle Filling Line

Bottle filling line is widely used in the pharmaceutical, health product, and food industries for counting and filling tablets, capsules, soft gels and gummy into jars, plastic or glass bottles. The system offers advantages such as high efficiency, precision, stability, hygiene, ease of operation, and maintenance, significantly enhancing production efficiency, reducing labor costs, and ensuring product quality.

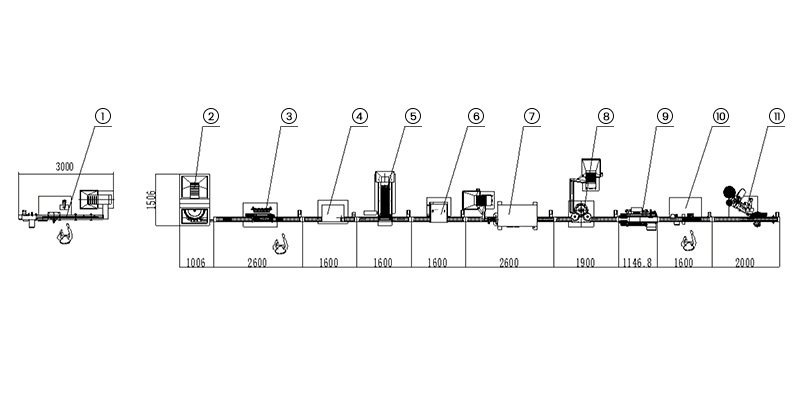

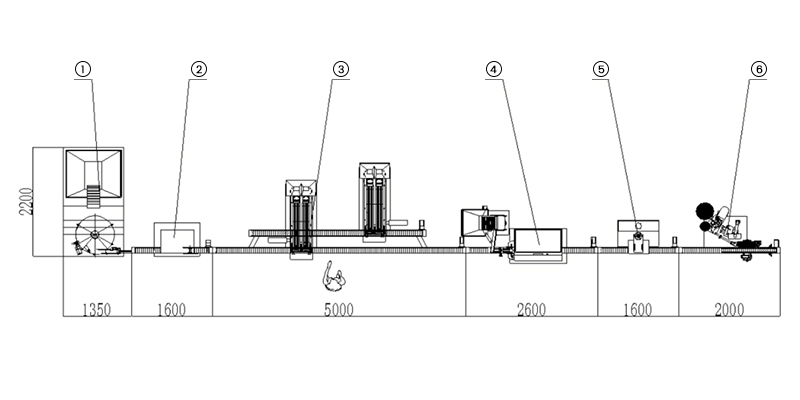

It consists of the following parts: bottle unscrambler, turntable, bottle air rinser, desiccant inserter, counting machine, capping machine, induction sealer, labeling machine and printer, etc. SCADA system and CFR21 are optional items. Advanced optical sensors and vibration feeding technology ensure accurate and efficient counting of tablets and capsules. Senieer bottle filling line in accordance with CE and FDA standard.

SCADA System Of Bottle Filling Line

Choose Your Bottle Filling Line

The bottle filling process includes several steps:

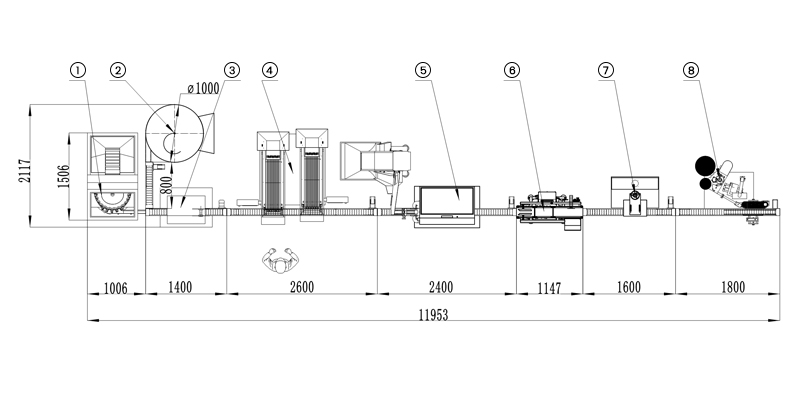

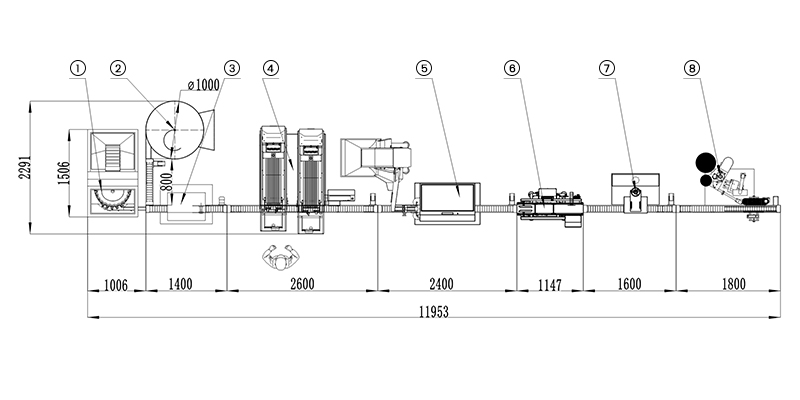

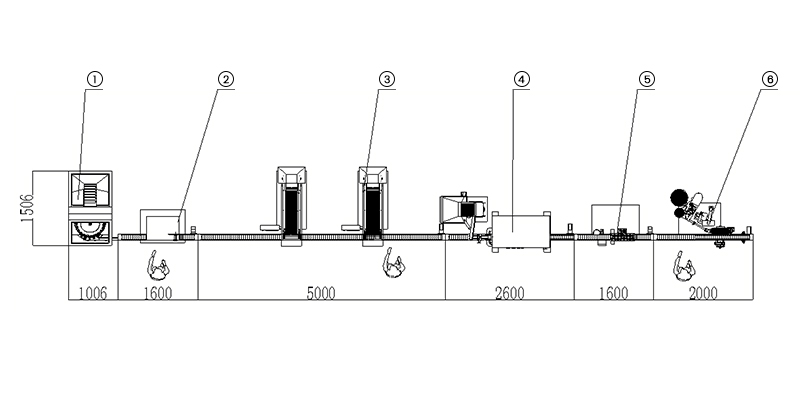

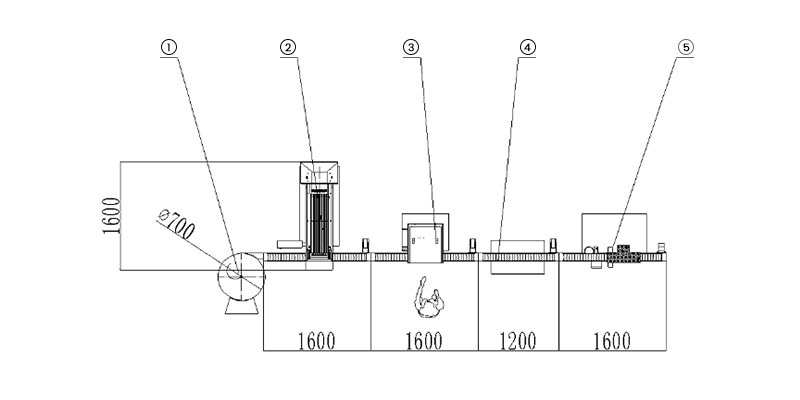

1. Bottle Unscrambler The bottle unscrambler is the first stage of a tablet counting line. This essential machine efficiently arranges and feeds empty bottles onto the production line, ensuring a continuous and organized bottle flow to the next station. Max. output around 150bottles/min, it depends on the bottle size.

2. Bottle Air Rinser Once the bottles are unscrambled, they are transferred via conveyor to the cleaning station. The bottle air rinser uses compressed air to remove dust, debris, and contaminants from the bottles, ensuring they are clean and ready for bottle filling and tablet/capsules/ pills/gummies counting.

3.Desiccant Inserter After cleaning, the bottles proceed to the desiccant inserter, which places desiccant packets inside the bottles to protect the product from moisture damage. The desiccant plug machine can also be replaced with a cotton plug machine or a sponge plug machine, depending on production needs. Max. output around 120 bottles/min. It depends on bottle size.

4. Tablet Counting Machine The core of the bottle filling line, the tablet counting machine, utilizes advanced photoelectric sensors to accurately count and dispense products into bottles. Senieer can customize the machine with 8, 12, 16, 32, or 48 channels to suit different product types, including tablets, capsules, pellets, soft gel, gummies, and candy. The automated system ensures high-speed, error-free counting while maintaining product consistency.

Senieer supplies two different kinds of counting machine which are camera visual counting machine and electronic counting machine.

5. Capping Machine Filled bottles move along the conveyor to the inline capper, which applies and secures threaded caps. This step ensures a tight, tamper-evident seal, protecting the product from contamination. Max. output around 150bottles/min. It depends on bottle size.

6. Induction Sealer The induction sealer further secures the bottles by using electromagnetic induction to generate heat, creating a hermetic seal on the cap. This step enhances product integrity and safety.

Senieer improve air cooling and water cooling, you can choose by yourself.

7. Labeling Machine Once sealed bottles move to the labeling machine, which applies labels accurately and consistently, ensuring clear product identification and compliance with industry standards. Senieer need to know: Your label size, whether you need print on the label.

Senieer improve three types of printers: inkjet printer, laser printer and hot ribbon printer.

8. Accumulation Table Positioned at the end of the line, the accumulation table acts as a buffer zone, preventing bottlenecks and maintaining a smooth production flow. It also facilitates the transition of finished bottles to further packaging processes.

Guidelines For Bottle Filling Line

As a leading manufacturer and supplier of bottle filling lines in the pharmaceutical industry, Senieer provides high-speed, automated, and hygienic counting solutions.

– High Accuracy Counting: Optical sensors ensure precise counting with minimal error.

– Multi-Industry Applications: Pharmaceutical, nutraceutical, and food industries.

– Flexible Counting Mechanisms: Suitable for various shapes and sizes of tablets and capsules.

– Automated Bottle Filling and Capping: Ensures continuous, efficient operation with minimal human intervention.

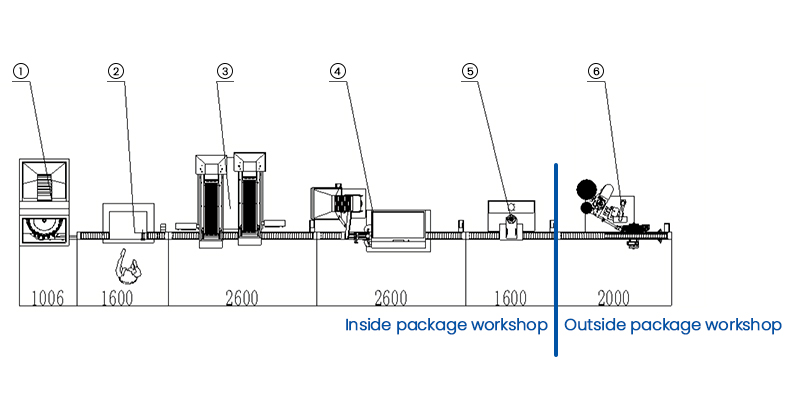

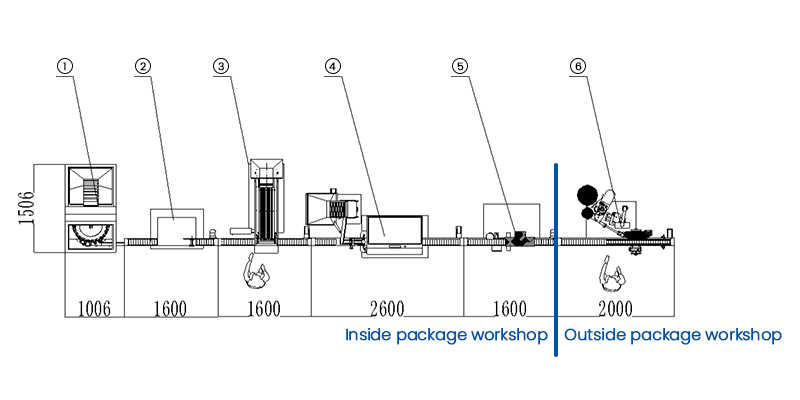

Different Types Of Bottle Filling Lines

Remark : 1.Production speed: capsule 0# , 60pcs/bottle, about 80bottles; capsule 0# , 100pcs/bottle, about 60-65bottles, tablet D12mm*5mm, 60pcs/bottle, about 90bottles; tablet D12mm*5mm, 100pcs/bottle, about 65-70bottles. P.S. : The exact speed need to be rechecked with the exact product. 2. Max bottle dia.: 100mm,Max cap dia.: 60mm,Max label label size: L230mm*H 100mm.

Remark : 1.Production speed: capsule 0# , 60pcs/bottle, about 80-bottles; capsule 0# , 100pcs/bottle, about 60-65bottles, tablet D12mm*5mm, 60pcs/bottle, about 90bottles; tablet D12mm*5mm, 100pcs/bottle, about 65-70bottles. P.S. : The exact speed need to be rechecked with the exact product. 2. Max bottle dia.: 100mm,Max cap dia.: 60mm,Max label label size: L230mm*H 100mm.

Remark : With 2 set PBDS-12 counting machine , 100pcs capsule 0#, about 80-90bottles/Min. , the exact production speed need to be checked with exact product specification.

Features Of Bottle Filling Line

Customization Meets Your Diverse Production Needs

Bottle filling line needs to be adaptable to different production scales, bottle types, and counting requirements. Senieer provides customized solutions to meet diverse needs.

Senieer offers professional technical support and after-sales services, including installation guidance, user training, and maintenance services. Senieer provides full verification documentation (such as IQ/OQ).

Senieer expert team is available to assist with troubleshooting and custom design solutions to ensure smooth production.

How To Choose The Right One?

When selecting a bottle filling line, key factors to consider include:

Senieer’s professional team will custom design and manufacture tablet counting lines to maximize your production efficiency and ensure compliance with industry regulations. Contact Senieer now to find the best solution for your manufacturing needs!