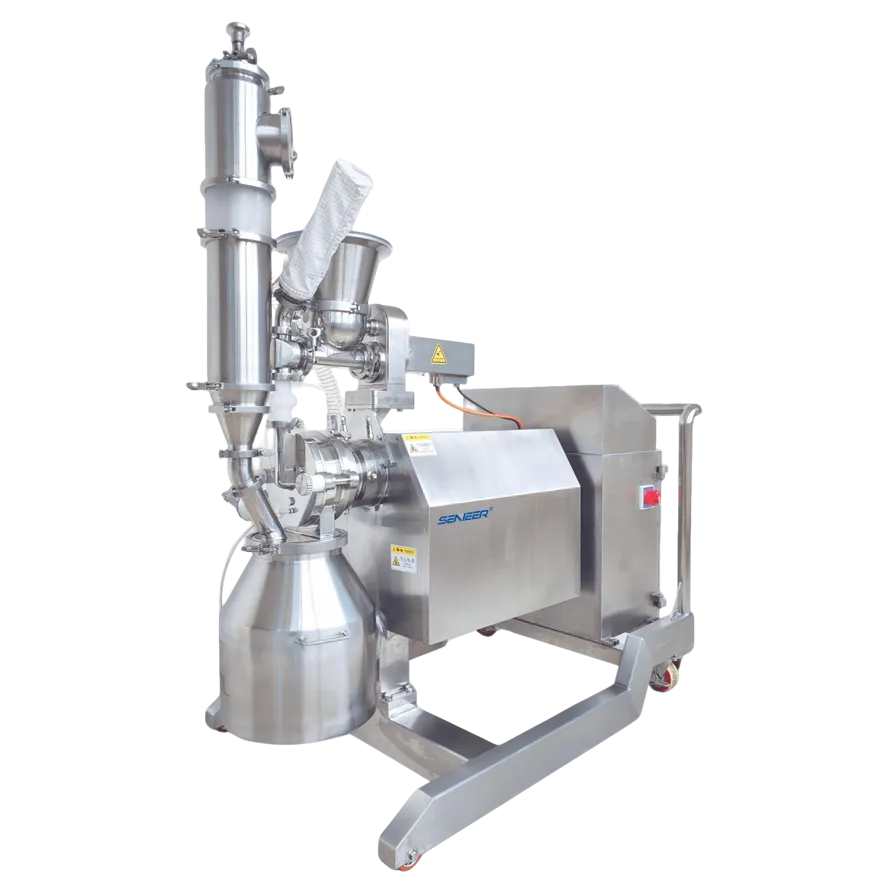

Current Product: SPM Series Pin Mill

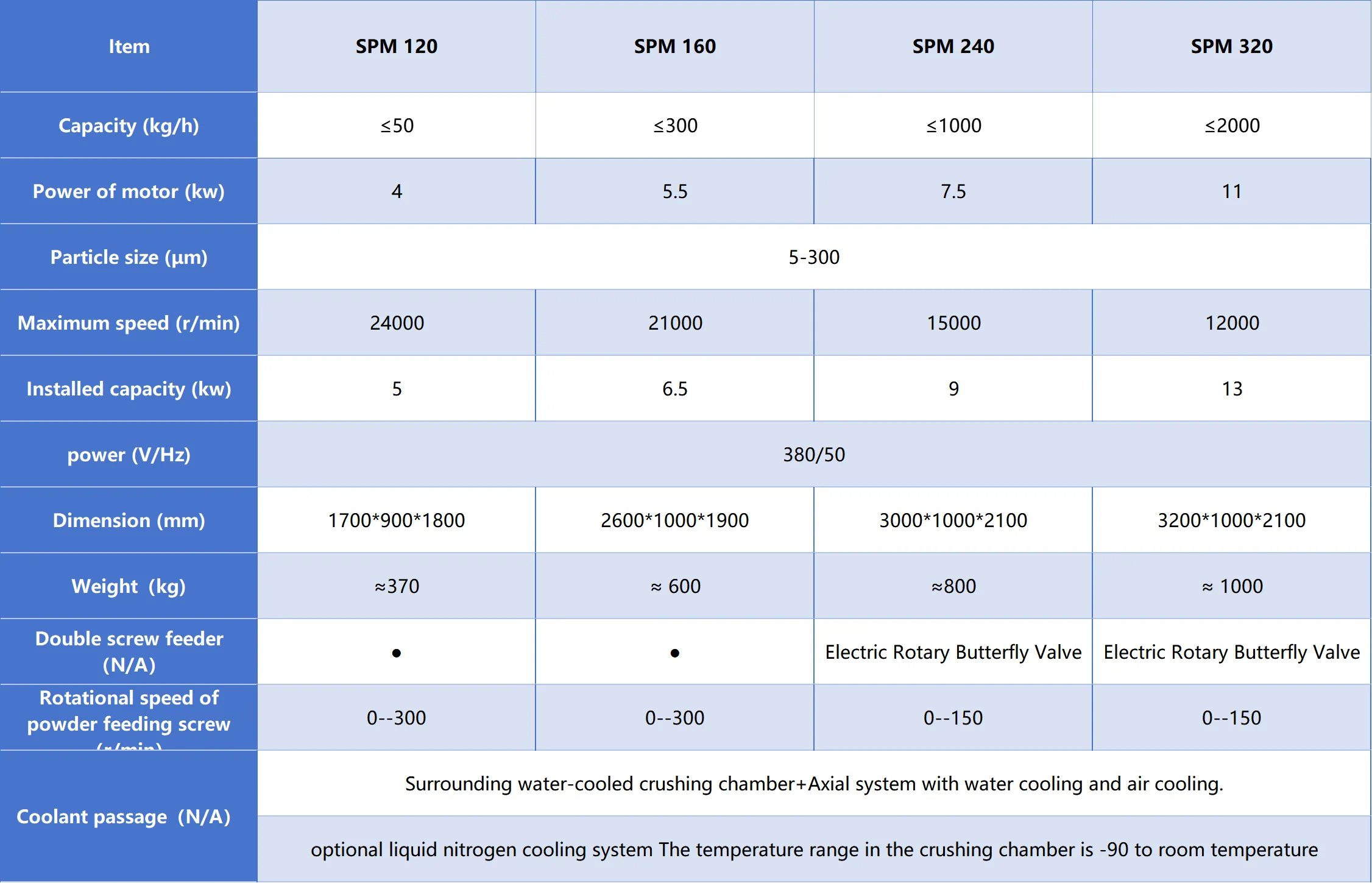

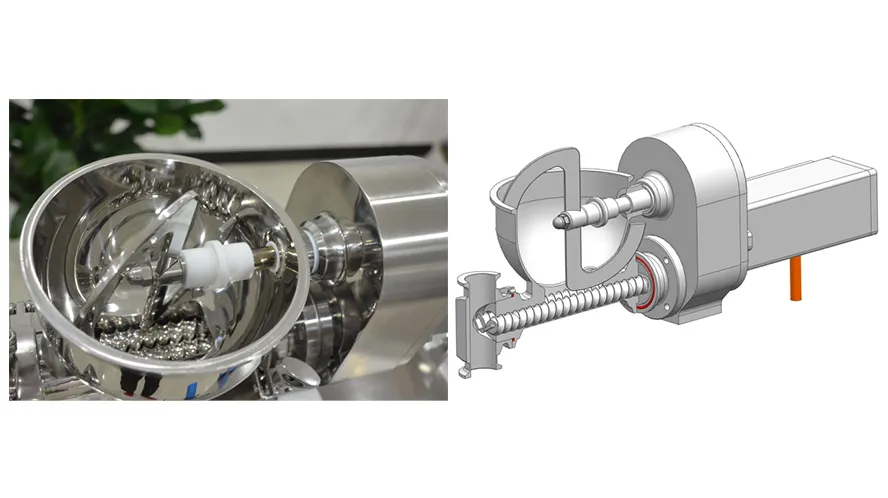

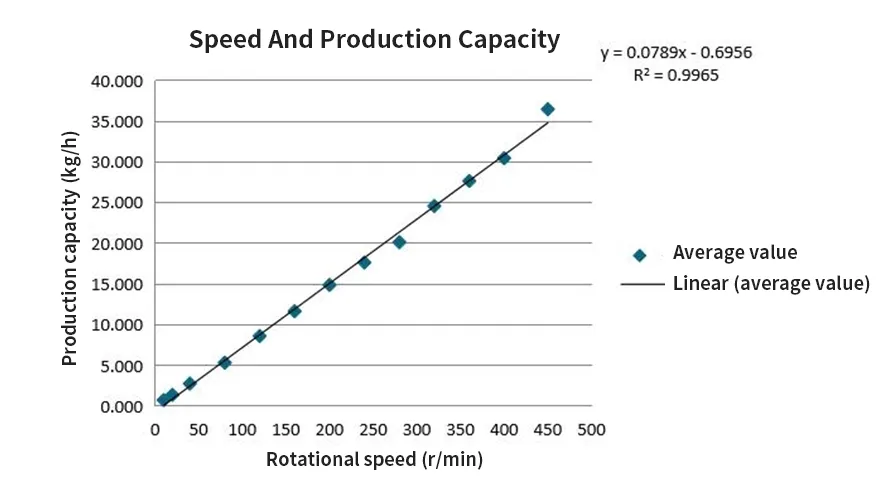

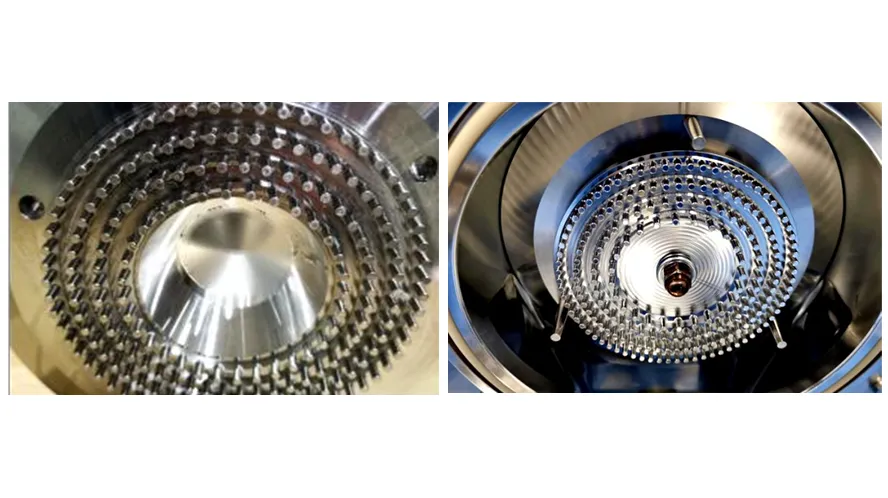

The Pin mill, a widely used industrial ultrafine grinder, is highly favored in countries such as the UK, Australia, Paraguay, the US, and Germany for its outstanding grinding performance and uniform particle size distribution. Its unique interlayer cooling water system ensures efficient operation by effectively preventing overheating during prolonged use, maintaining the equipment in a stable and optimal temperature environment for continuous operation. Come and contact us.

.webp)