Customized Coffee Processing Equipment Solutions Help Malaysian Coffee Brands Achieve Dual Upgrades in Quality and Efficiency

Project Background

In the third quarter of 2025, a medium-sized enterprise in Malaysia that specializes in the production of coffee mixtures (serving local chain brands and catering clients) sought equipment upgrades. Its core demands focused on three aspects:

- Resolving the issue ofinadequate mixing of auxiliary materials.

- Achievinglarge bag packaging of coffee mixtures.

- Ensuring that the entire process complies with Malaysian food production certification standards.

After multiple rounds of comparisons, the enterprise finally chose to cooperate with us and introduced a complete set of coffee processing equipment solutions.

Chapter 1 : What is the process flow?

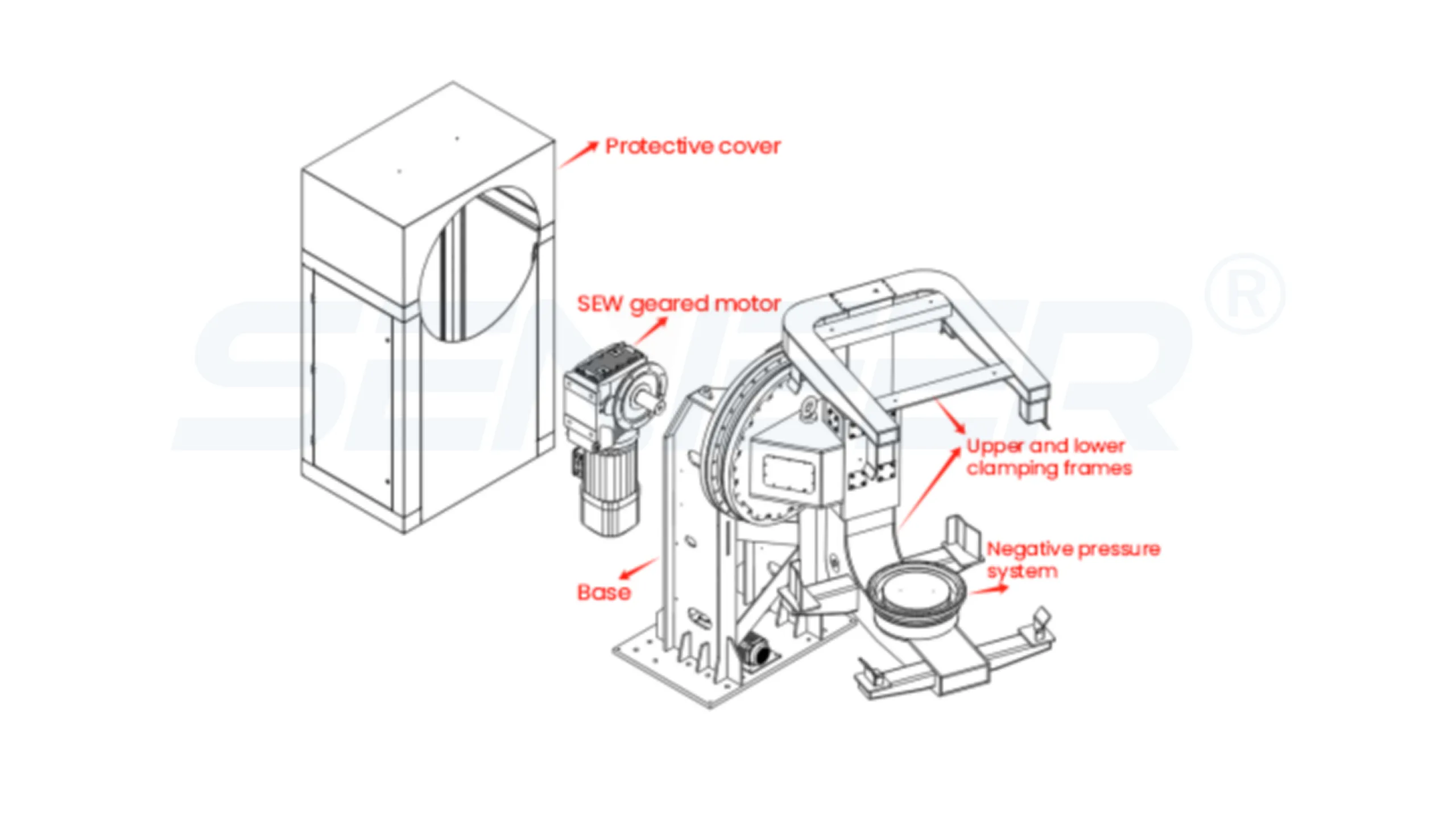

The forklift lifts materials to the feeding platform. Operators manually open bags and feed materials into the feeding system (including dust removal, impurity screening, and strong magnetic iron removal). Materials enter the IBC bin. When the weight reaches the preset threshold, feeding stops. The sealing manhole cover is closed, and nitrogen is injected through the inlet to displace air in the IBC bin. The IBC bin containing materials is then transferred to the bin blender using the forklift. The bin blender automatically completes clamping, mixing, and stopping at designated points according to preset speed and time. After mixing, the forklift transfers the IBC to the unloading platform. The conical valve unloading system automatically dispenses materials based on preset quantities, which pass through the metal detection system before reaching the temporary storage bin for weighing and packaging. The weighing and packaging machine accurately performs weighing and bagging through screw speed control and weighing systems, then transfers materials via conveyor belt to the external packaging process.

Chapter 2: What problems did we encounter during the technical handover and how did we solve them?

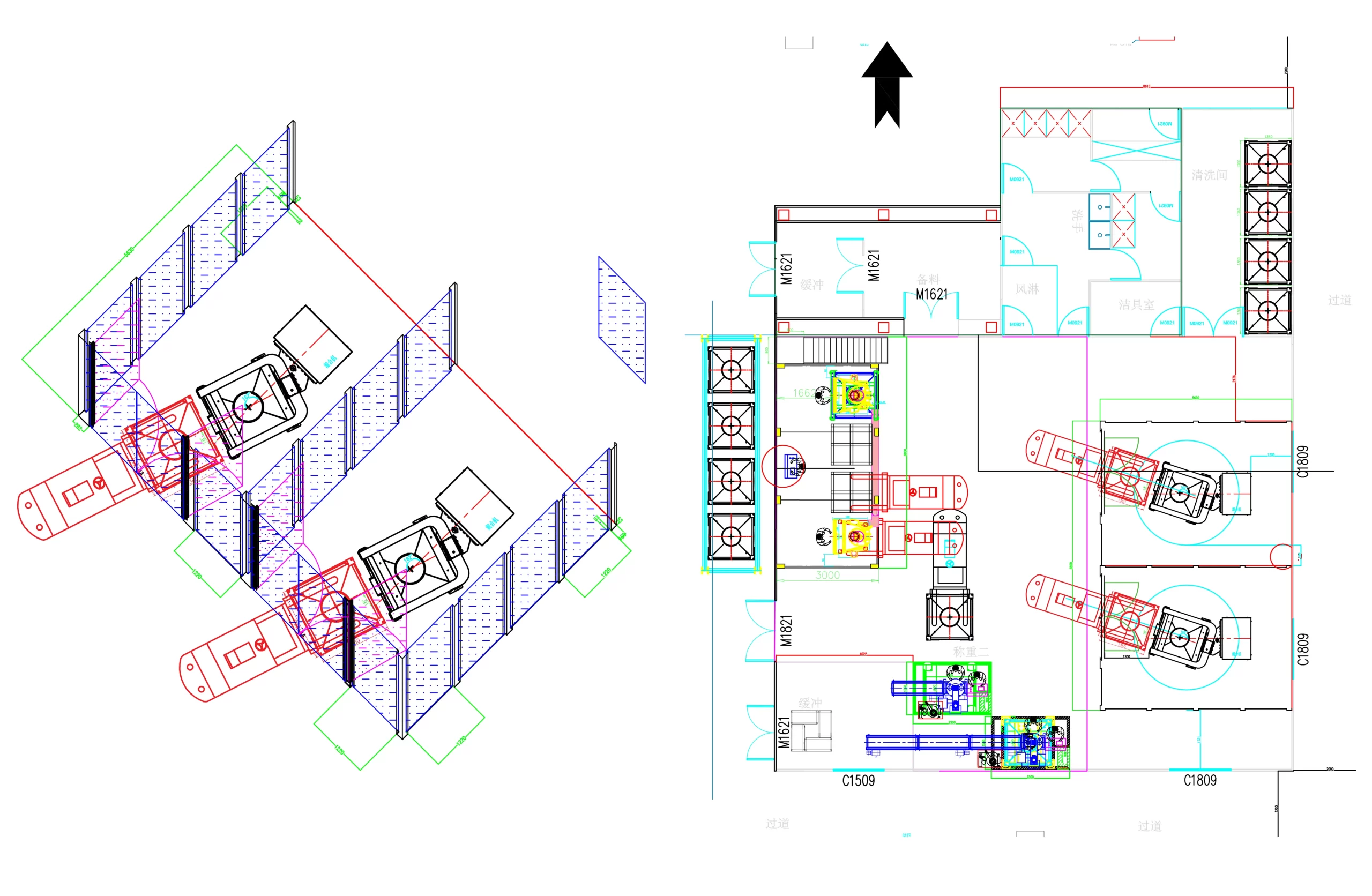

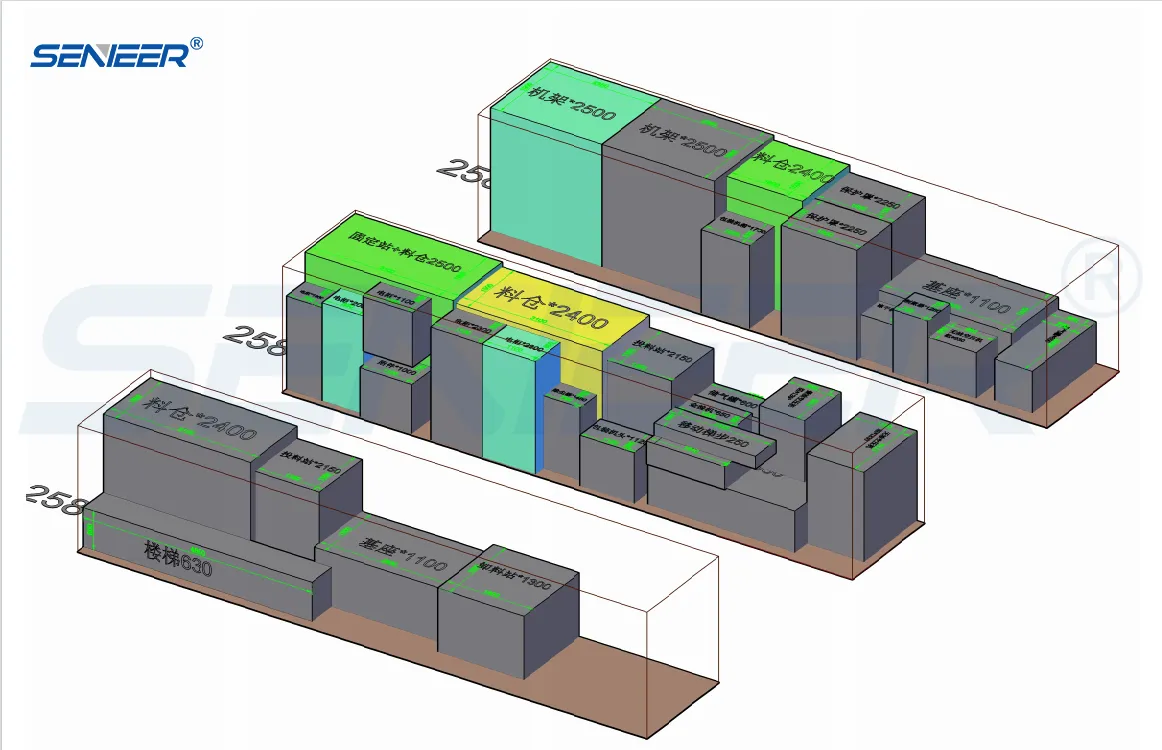

By analyzing core elements including material specifications, detailed process requirements, and on-site spatial measurements, we develop a comprehensive solution framework. Through multi-phase discussions with the client’s technical team, production managers, and leadership, we optimize equipment compatibility, operational efficiency, and maintenance costs. This results in a complete service package featuring customized production equipment, smart factory layout plans, and precision installation positioning. We offer three tailored solutions for different budget ranges, production capacities, and technical approaches. Through multidimensional comparative analysis, simulation testing, and ROI calculations, we refine solutions based on real-world production scenarios. Ultimately, we collaborate to select the optimal implementation plan that balances cost-effectiveness with forward-looking capabilities.

Chapter 3: Efficient packing and shipping to Malaysia.

All delivered equipment has now been fully commissioned, and we promptly arranged for a professional logistics team to handle transportation. Considering the substantial size and weight of the equipment, along with safety concerns during transit, we selected appropriate transport vehicles and packaging methods. The equipment was comprehensively packed using sturdy wooden crates and protective materials to ensure it remains undamaged throughout the long-distance journey. Simultaneously, we maintained close communication with the logistics provider to develop a detailed transportation plan and route. We continuously monitored the shipment’s status in real time to ensure the equipment arrived at the customer’s site safely and on schedule.

Chapter 4: How to comply with local regulations in Malaysia?

During the technology transfer process, Senieer proactively engaged with local Malaysian certification authorities, preparing comprehensive documentation as required and actively supporting the certification procedures. The company conducted thorough research and strictly adhered to local regulations and standards for the import of equipment. To address Malaysia’s specific requirements in equipment safety and environmental protection, Senieer incorporated these considerations during the design phase, ensuring all machine parameters and performance metrics comply with local specifications. This approach enabled Senieer to provide customers with the most tailored solutions.

Senieer evaluates clients’ User Requirements Specifications (URS) and provides expert recommendations to fulfill their needs. When necessary, laboratory machine testing is conducted. The company collaborates with clients to finalize design and drawings, covering cleanroom layout, 3D modeling, and specialized designs.

Senieer’s factories manufacture machinery according to final blueprints, using materials compliant with local environmental standards to ensure equipment compliance from the source. Regular inspections of the production process are conducted to monitor quality and progress. Upon completion, the equipment undergoes Factory Acceptance Testing (FAT), which includes welding procedures, pressure testing, trial runs, and product inspections. Our professional engineers personally conduct the acceptance and promptly provide feedback to their Malaysian counterparts. The acceptance is only deemed successful after mutual approval of quality standards. Additionally, Senieer handles the entire process of installation, commissioning, and training to ensure the machinery operates stably and requires minimal maintenance.