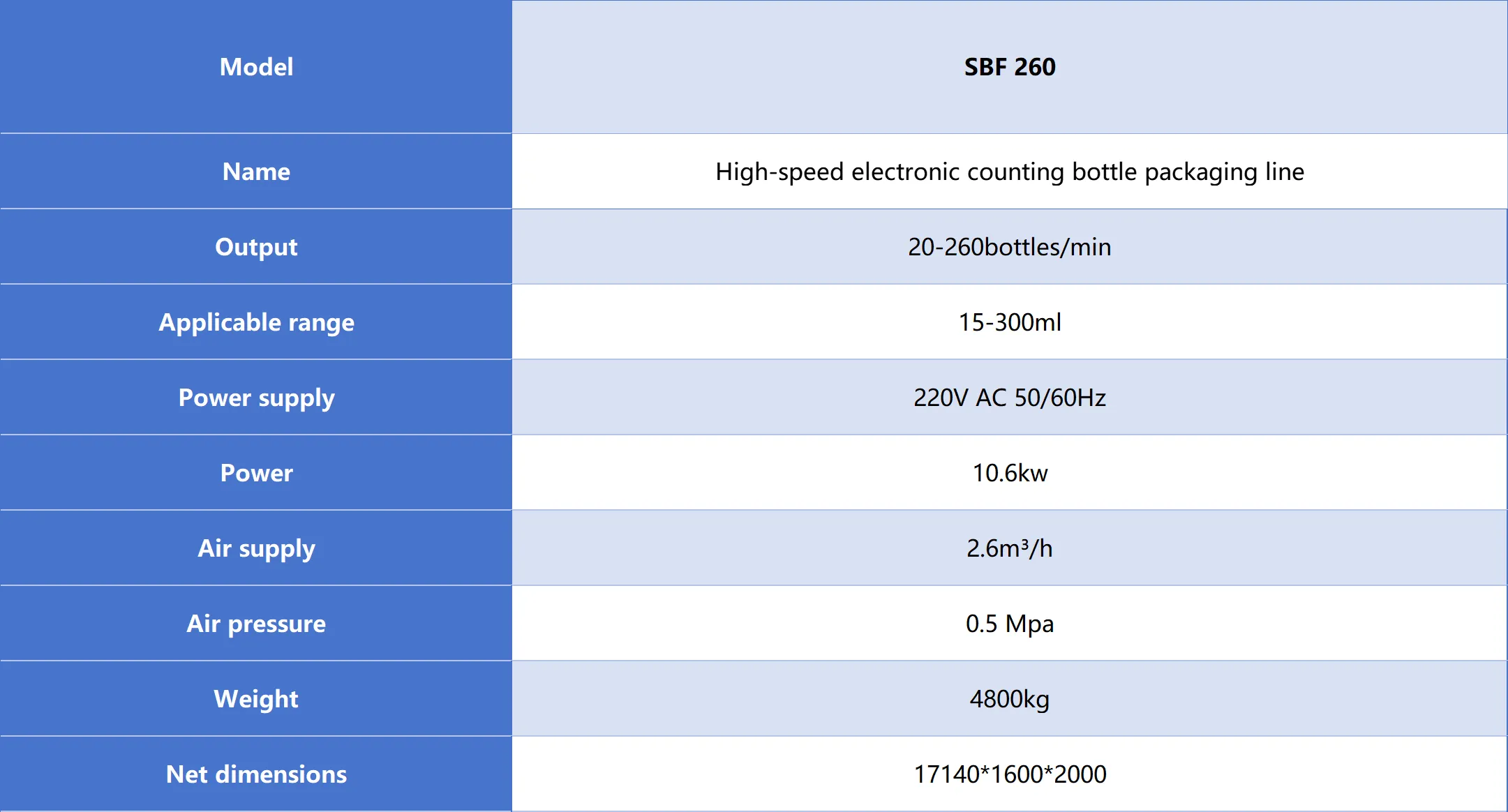

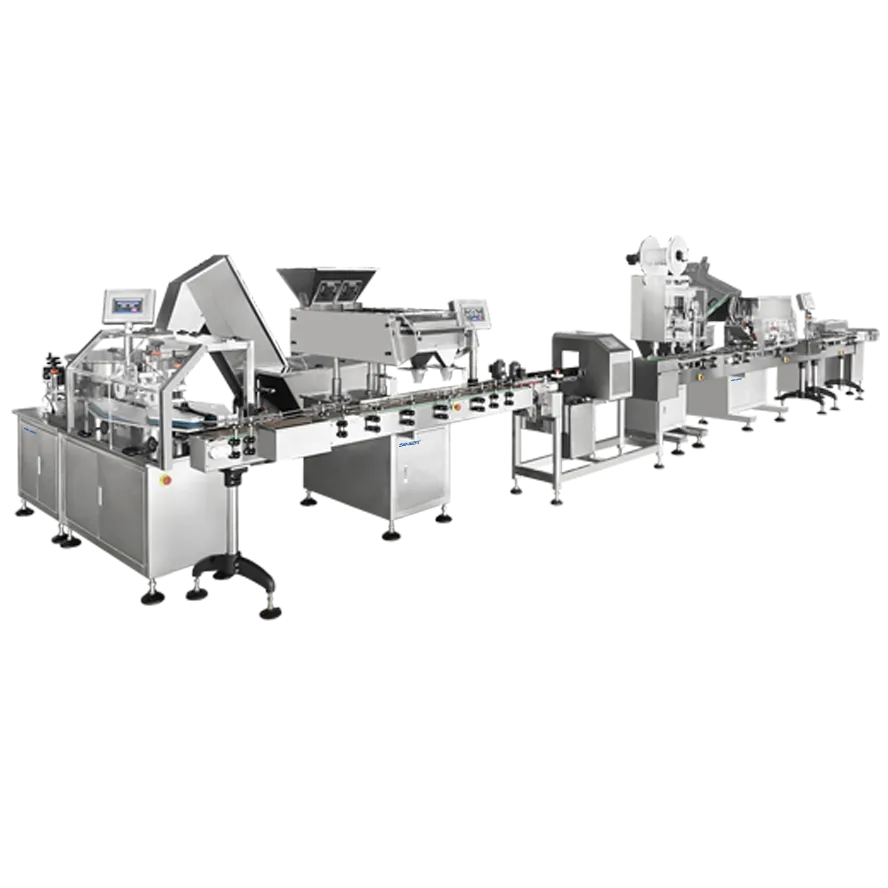

Current Product: SBF 260 Bottle Filling Line

The SBF 260 bottle filling line is an important production line for large-scale bottled production. It can choose from a variety of filling materials, including tablets, capsules, pills, granules, and other solid products, and can also use non-circular bottles for filling. All packaging links are closely coordinated to complete the bottling task efficiently and conveniently. Come on, the whole series of machines is on sale.