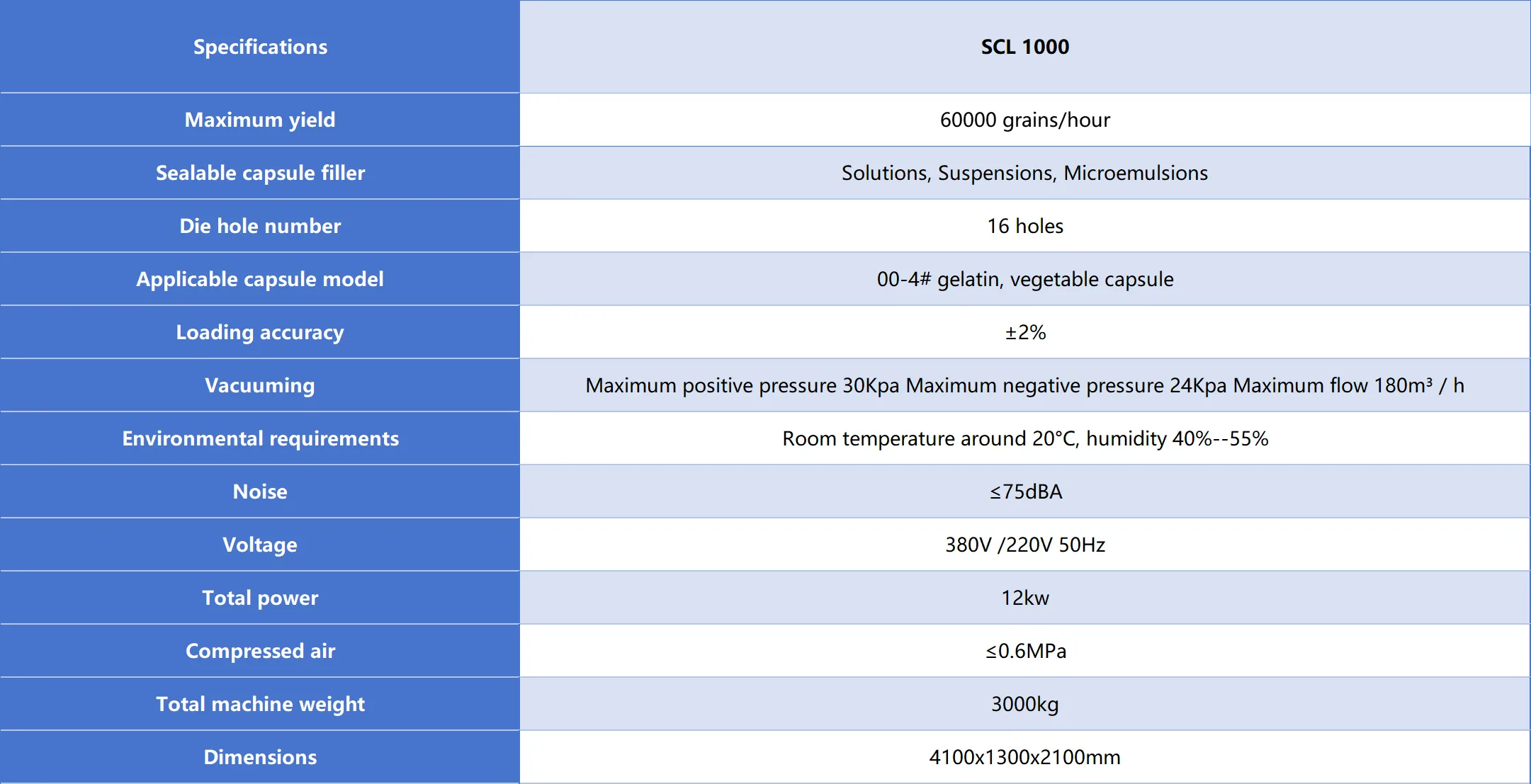

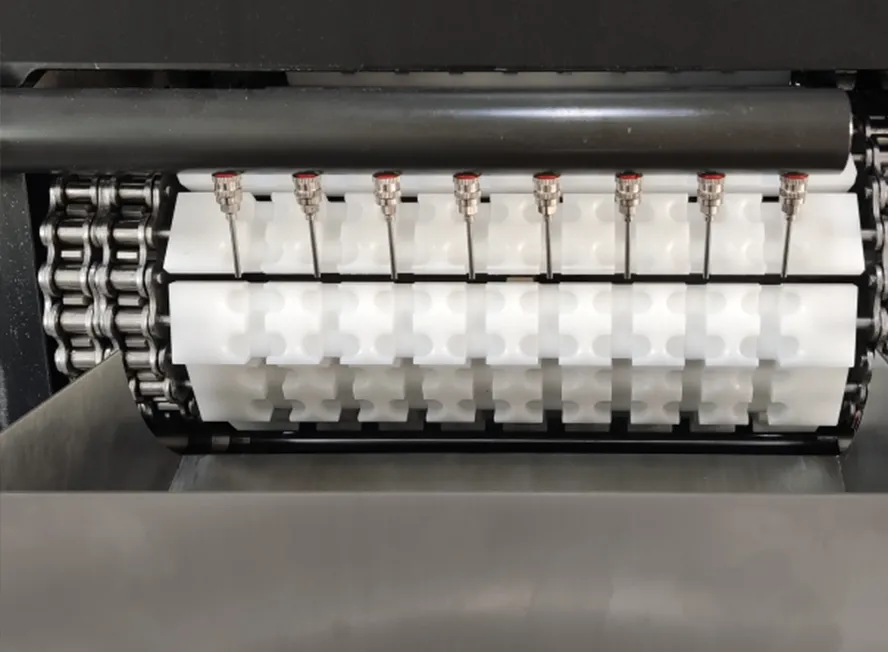

Current Product:SCL 1000 Liquid Capsule Filling Machine

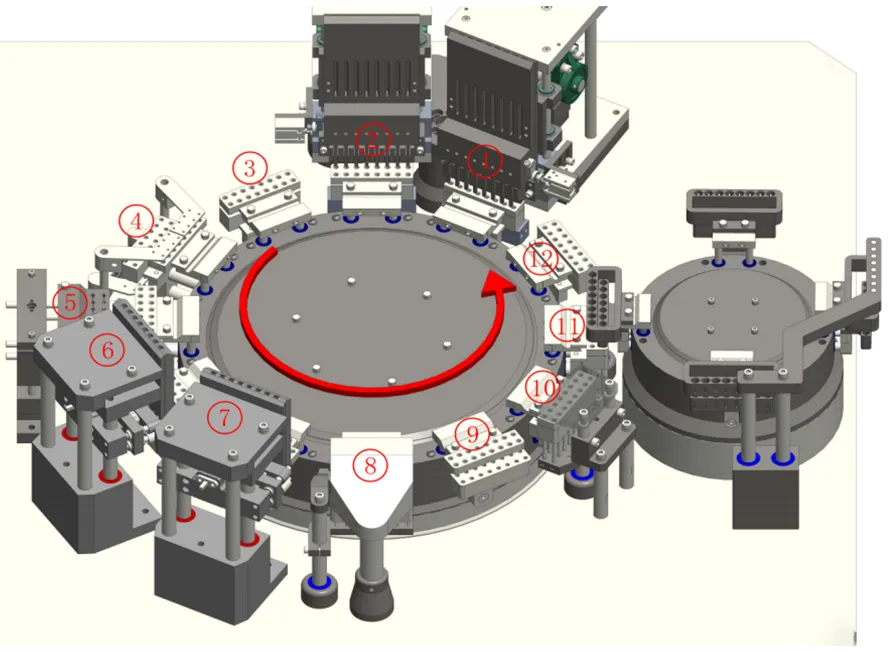

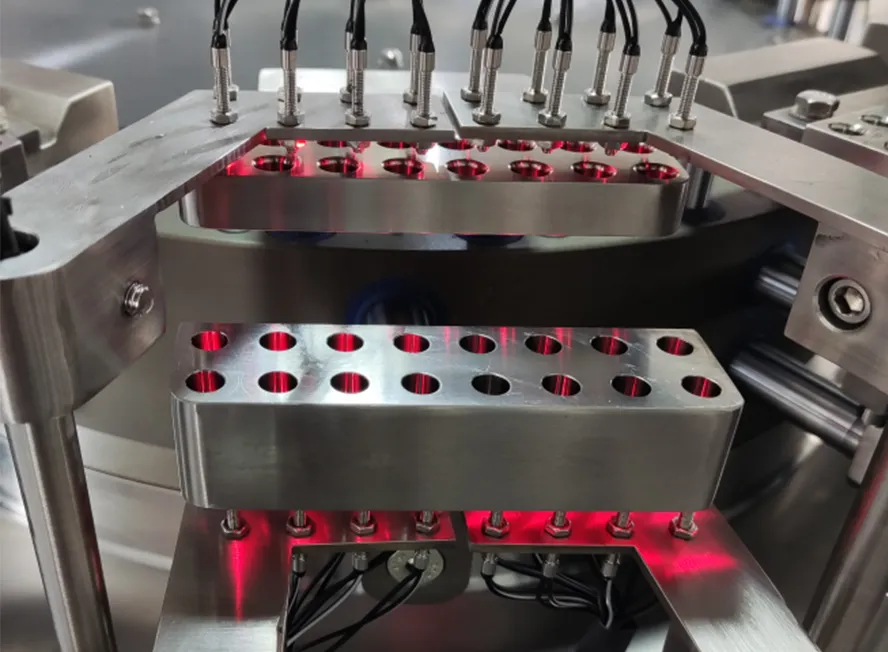

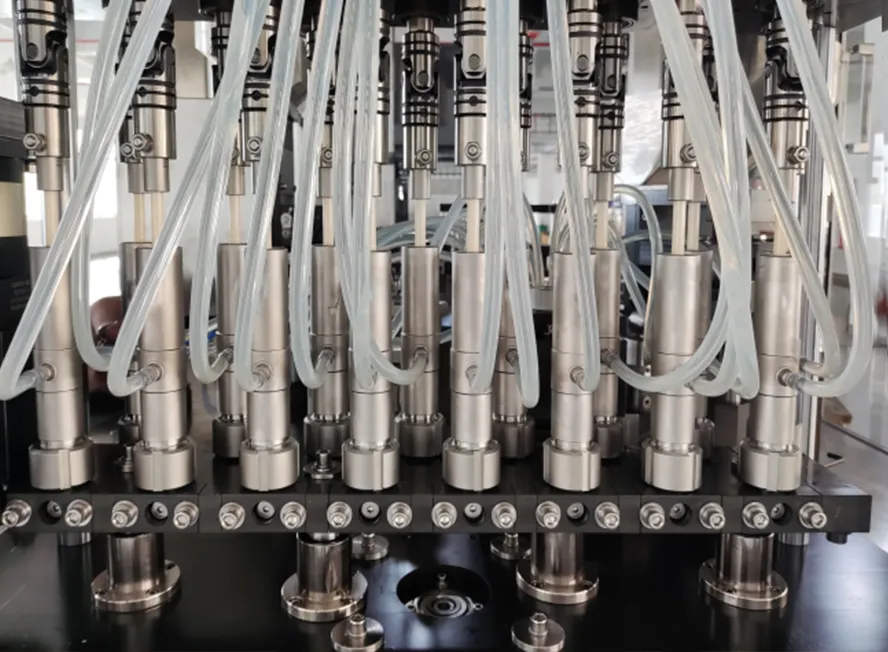

The SCL 1000 liquid capsule filling machine is the crystallization of Senieer technology. While ensuring the quality of dual-chamber capsule filling and sealing, it can also be used for large-scale production. It is the best choice for the research, development, and production of new drugs and high-standard pharmaceutical enterprises. If you want to know more, please feel free to contact us.