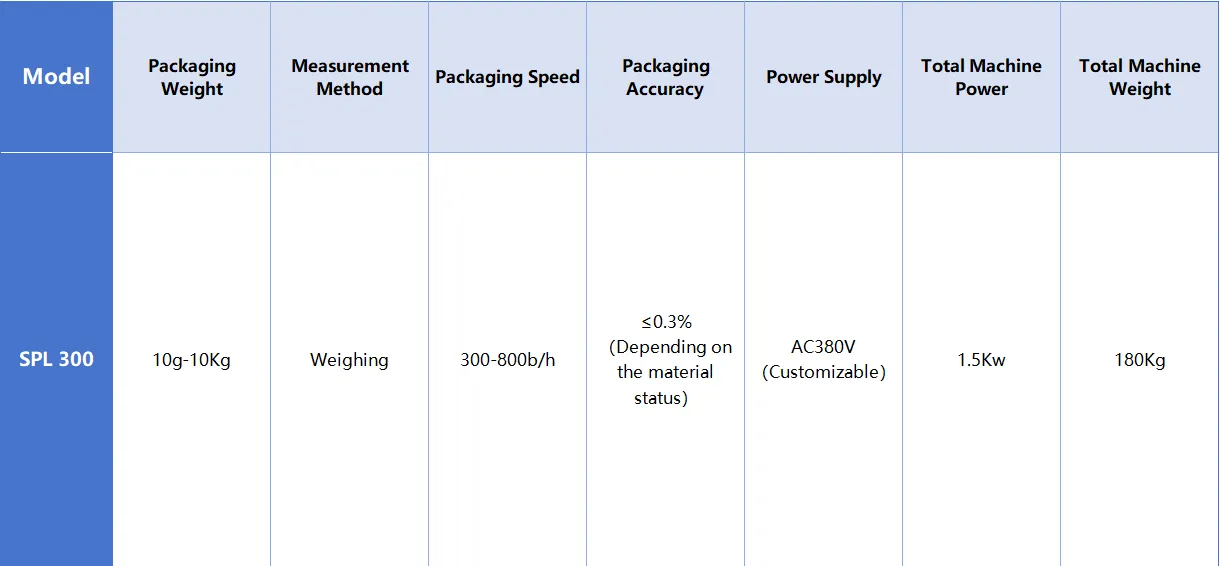

Current Product: SPL 300 Podwer Filling Line

The SPL 300 Powder Fill Line adopts a modular design, allowing users to select and combine core components based on their specific product characteristics and production needs. It fully complies with GMP requirements for process hygiene, anti-pollution, and quality traceability. We provide customized solutions to address customer challenges in powder filling and have established cooperative relationships with clients in multiple countries and regions, covering pharmaceutical, food, healthcare, and chemical industries. Look forward to your inquiry!