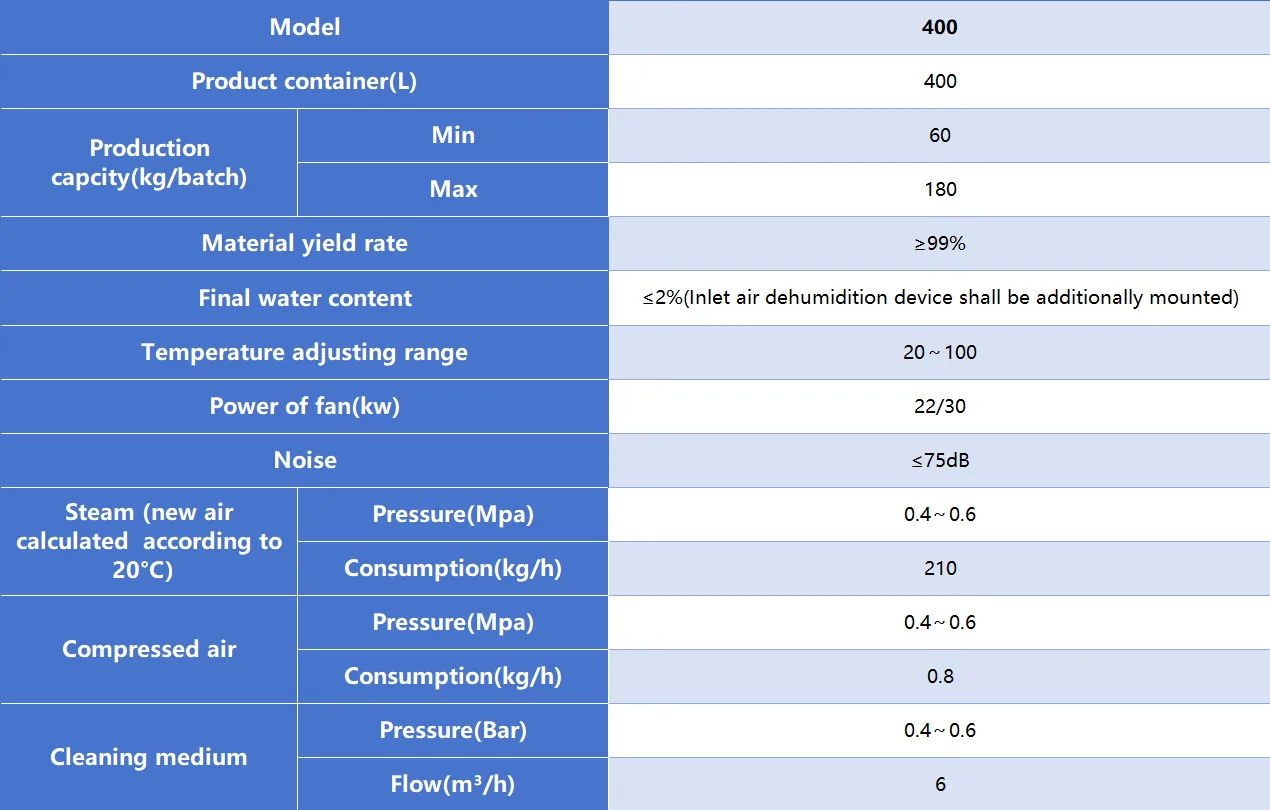

Current Product: FBG 400 Fluid Bed Granulator

The FBG 400 Fluid Bed Granulator adopts a tower design, and the entire machine structure adopts an arc transition with no dead ends and is easy to clean. It fully complies with GMP requirements for anti-pollution of processes and process equipment. Senieer provides more detailed services to solve customer’s granulation problems and has reached cooperative relationships with many countries such as the United States, Mexico, Canada, Spain, Egypt, Saudi Arabia, etc.