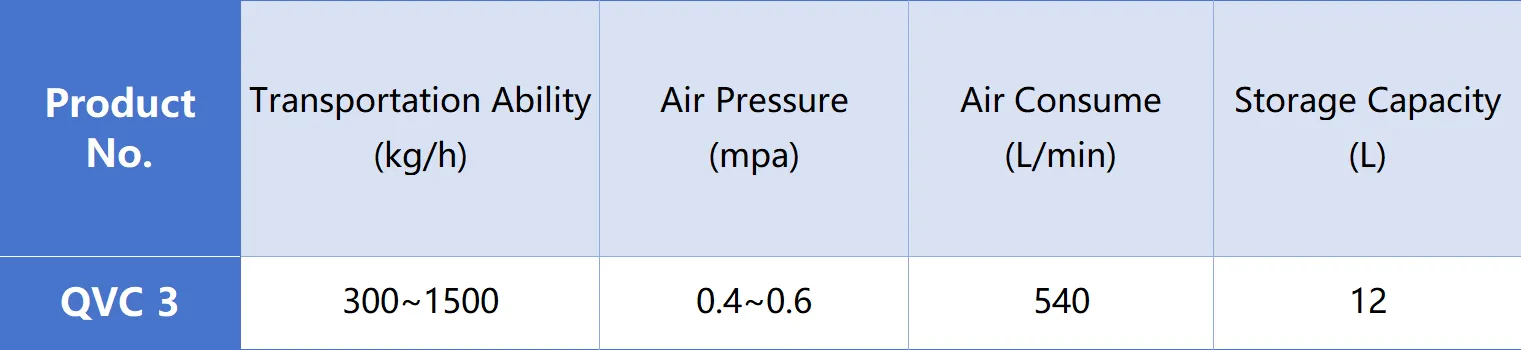

Current Product: QVC 3 Vacuum Feeder

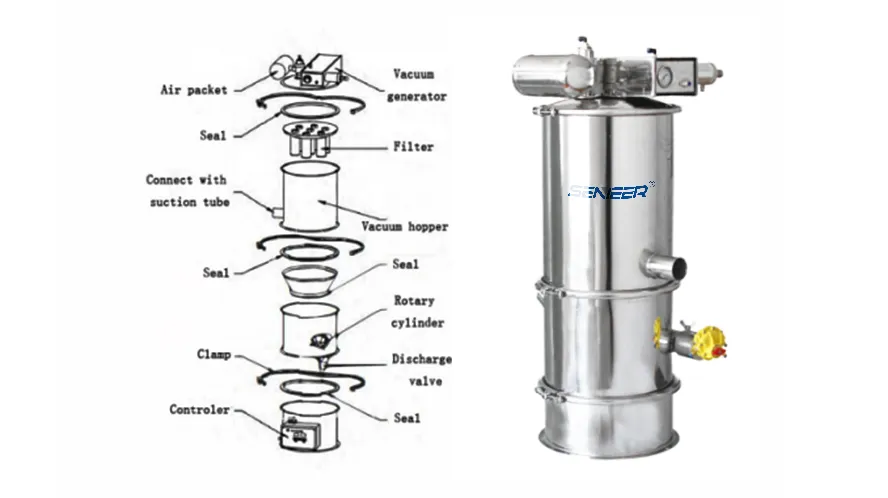

QVC 3 Vacuum Feeder is equipped with a vacuum generator, which produces a high vacuum to prevent the stratification of the transported materials and ensure the uniformity of the mixed material composition.It is the preferred equipment for automatic feeding of tablet press, capsule filling machine, dry granulator, packaging machine, hammer mill, vibrating screen and other machinery.