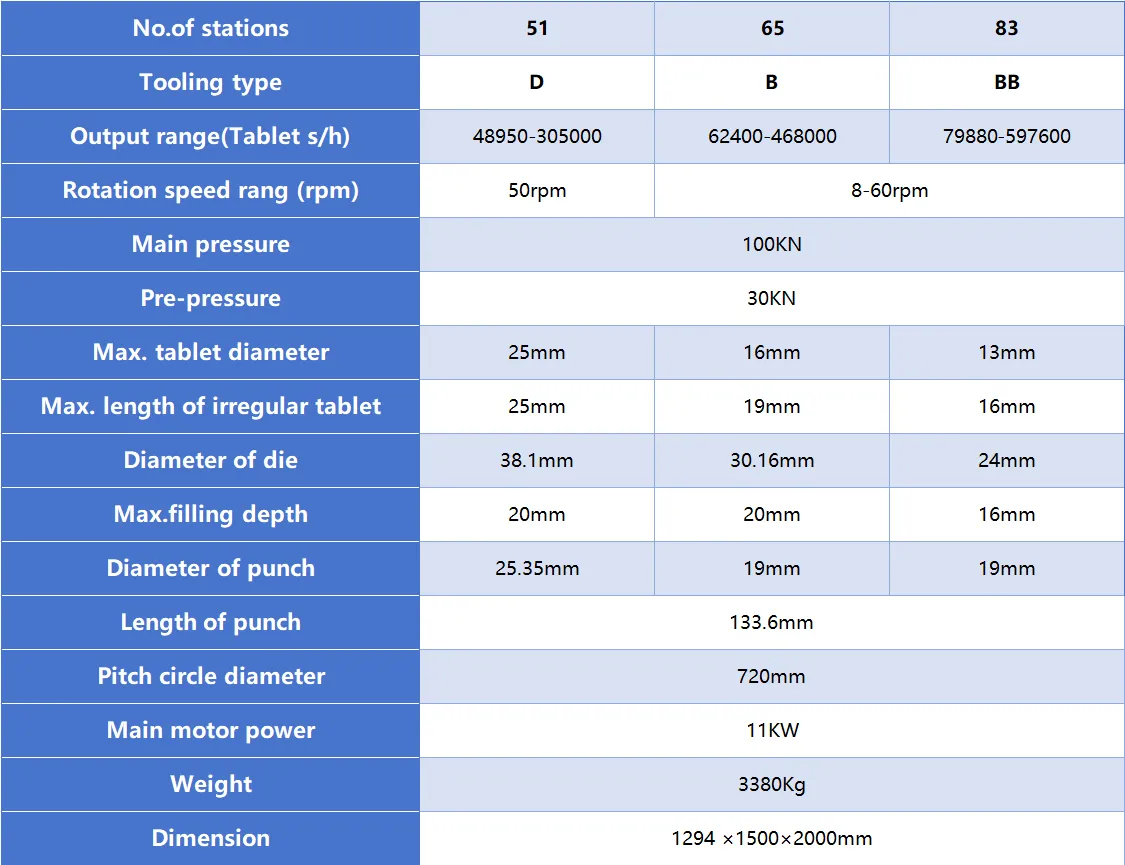

Current Product: High Speed Rotary Tablet Press Machine

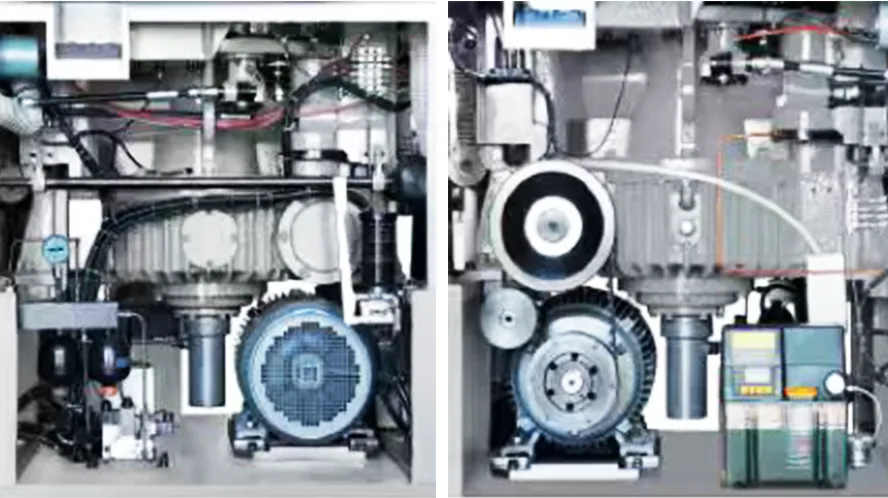

The high speed rotary tablet press machine has become an sophisticated equipment in the modern tablet press industry with its efficient capacity and process improvement.The automatic double discharge designs allow for sustainable tablet press production, which increases the production scale and efficiency.We supply our products to international markets spanning Peru, the US, the Middle East, South Africa, Indonesia, and beyond. Additionally, we offer comprehensive service solutions tailored for customers around the global clients.