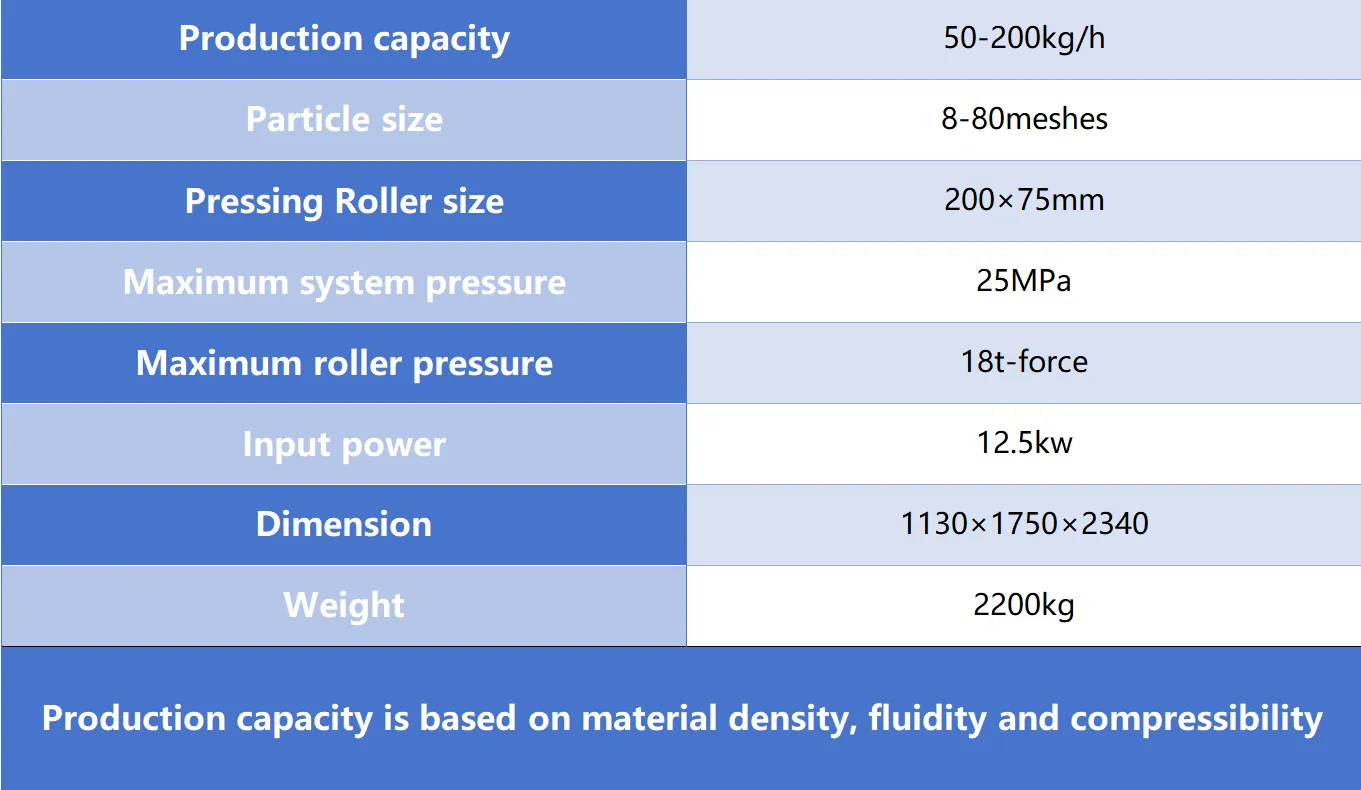

Current Product: SRC200 Dry Granulator

The working process of dry granulator is very simple and easy to use. It maninly uses tow continuously rotating press rollers to compress dry powders or granules to form sheets or flakes of powder. Then the sheets of powder will be milled into small and dense dry granules by milling. Senieer’s SRC200 Dry Granulator can help you make dry granules with excellent flowability, and density. Welcome to contact us to learn about more details.