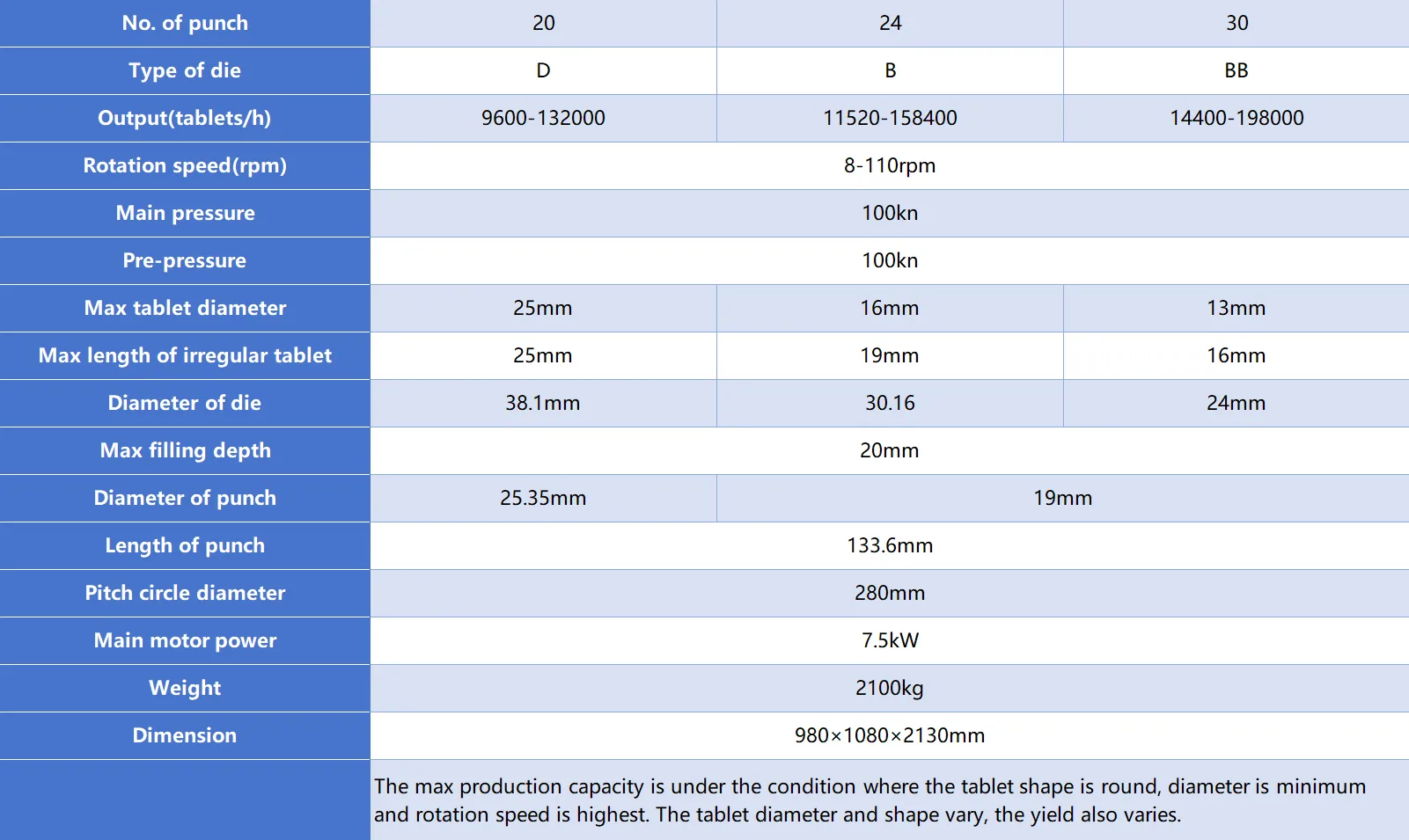

Current Product: STP280 Tablet Press Machine

With more than 30 years in the pharmaceutical industry, our engineers has abundant professional experiences in the manufacturing of tablet press machine. All our products are compliant with cGMP standards. The enclosed contained double layers three impellers force feeding, which enhances drug powder filling capability, can effectively avoid the segregation phenomenon of coarse and fine powder. For more details, welcome to contact us!