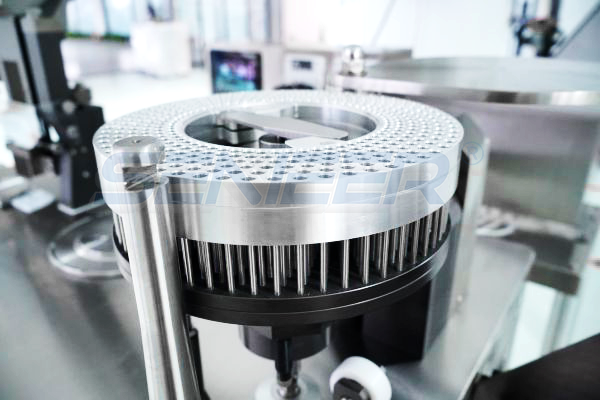

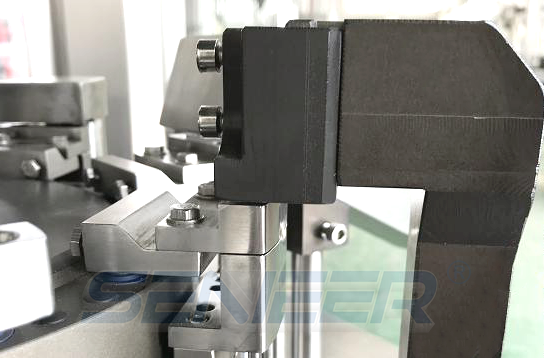

Current Product: Semi Automatic Liquid Capsule Filling Machine

Our semi automatic liquid capsule filling machine has a reasonable and simple structure design, beautiful appearance, efficient and smart filling and sealing devices, as well as meeting GMP standards. It suits common standards capsule sizes from 00# to 5#. Others such as gelatin and vegetarian capsules also available. It can fill both liquid and solid dosages only just replacing related molds. The filling error is within ±1–2%. Choose Senieer semi automatic liquid capsule filling machine, empowers your factory or lab production.