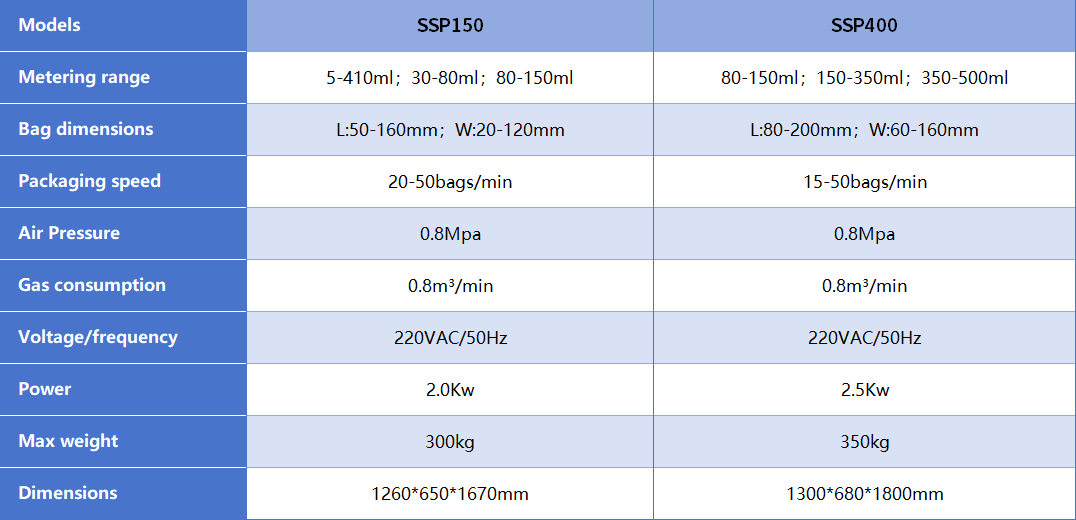

Current Product: Liquid Sachet Filling Machine

Our liquid sachet filling machine series offer adjustable filling and packing speed from 20-50 to 15-50 bags per minute, suitable for small and medium-scale production needs. If you have a higher production speed needs, please contact us to offer a customized project for you. With a professional team of more than 30 years, we promise to offer you satisfying solutions.